Modular hose reel

a hose reel and module technology, applied in the field of reels, can solve the problems of single, limited space, and predetermined size of the hose reel that may not be suitable for each application, and achieve the effect of easy custom manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

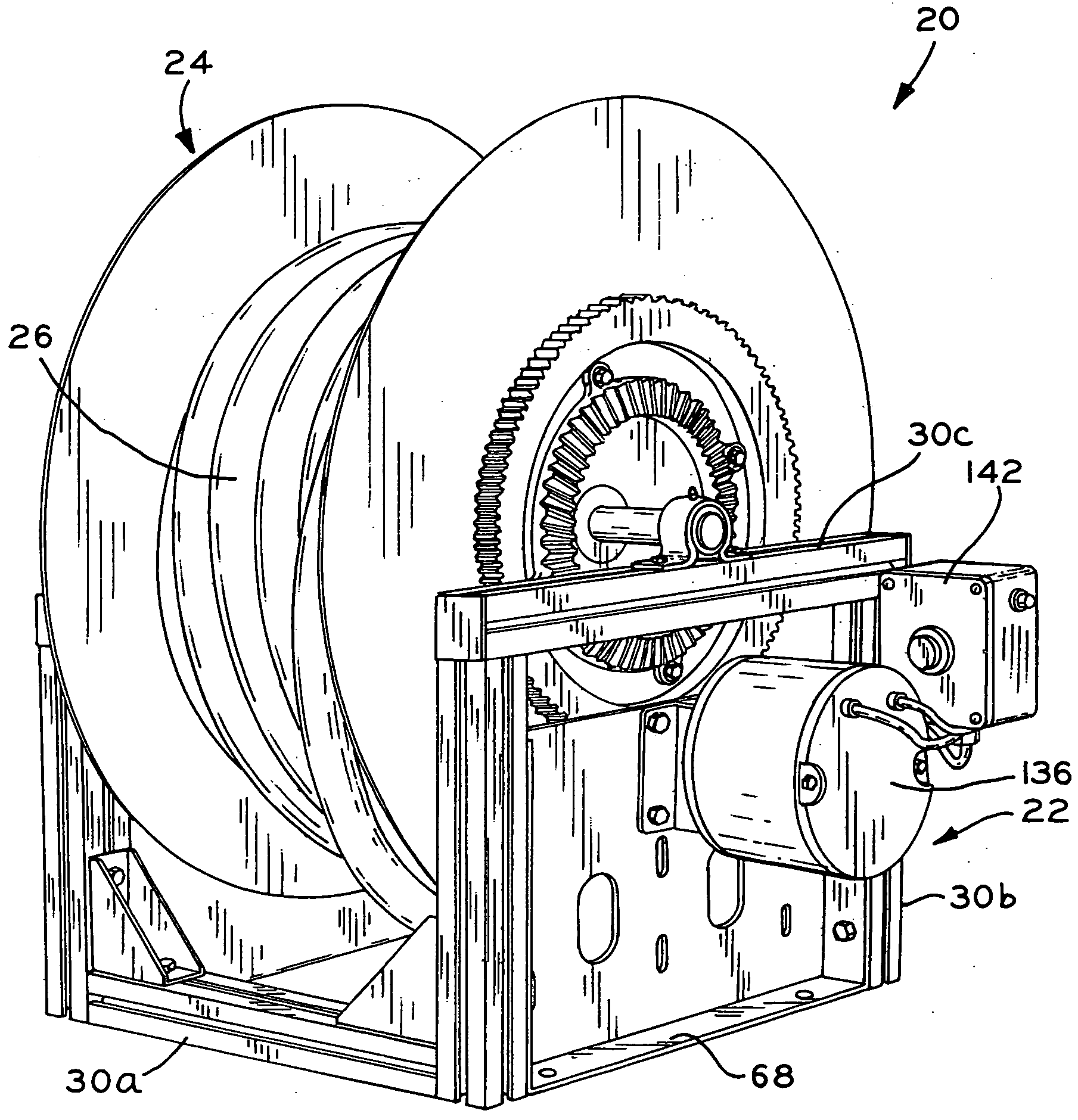

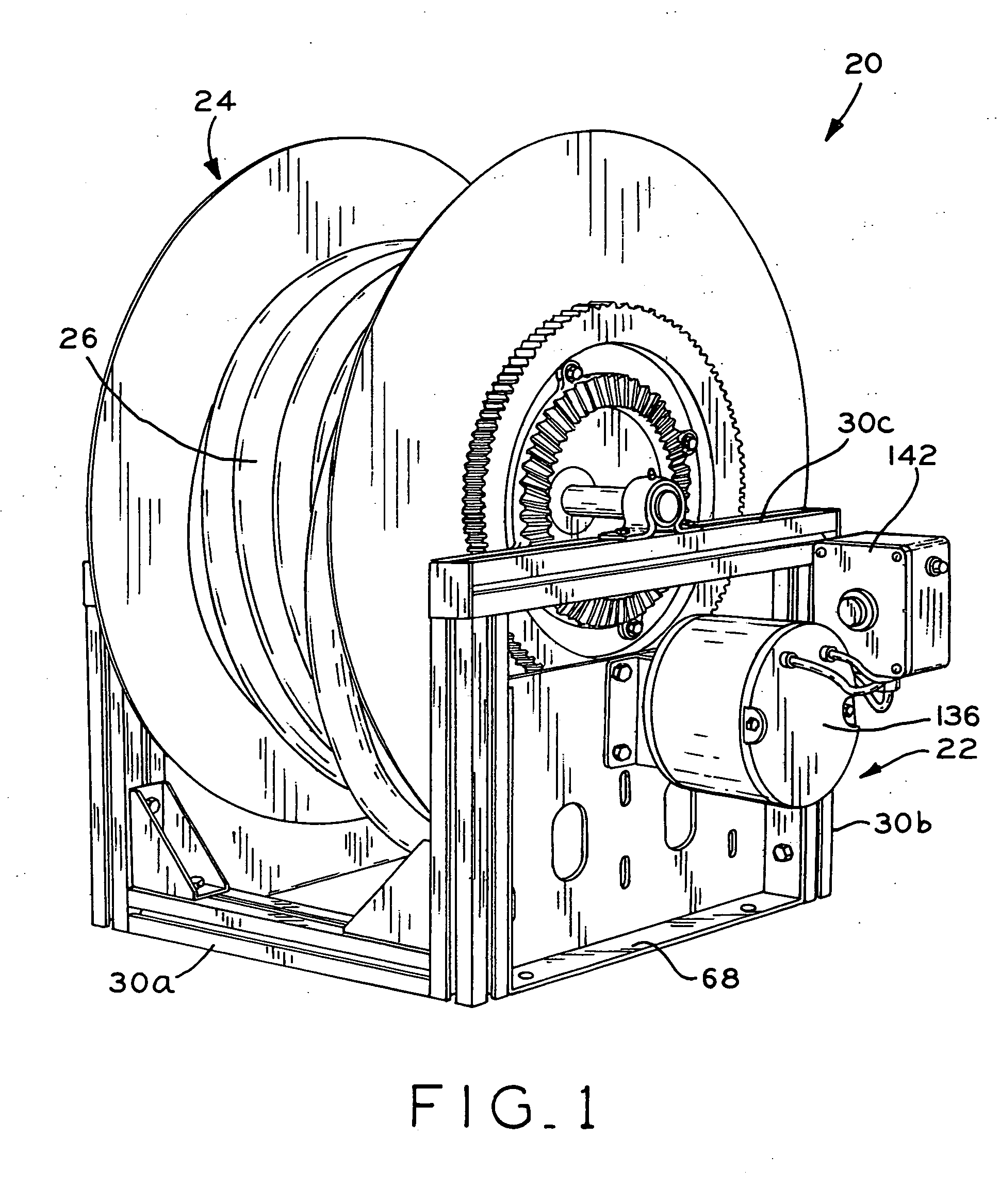

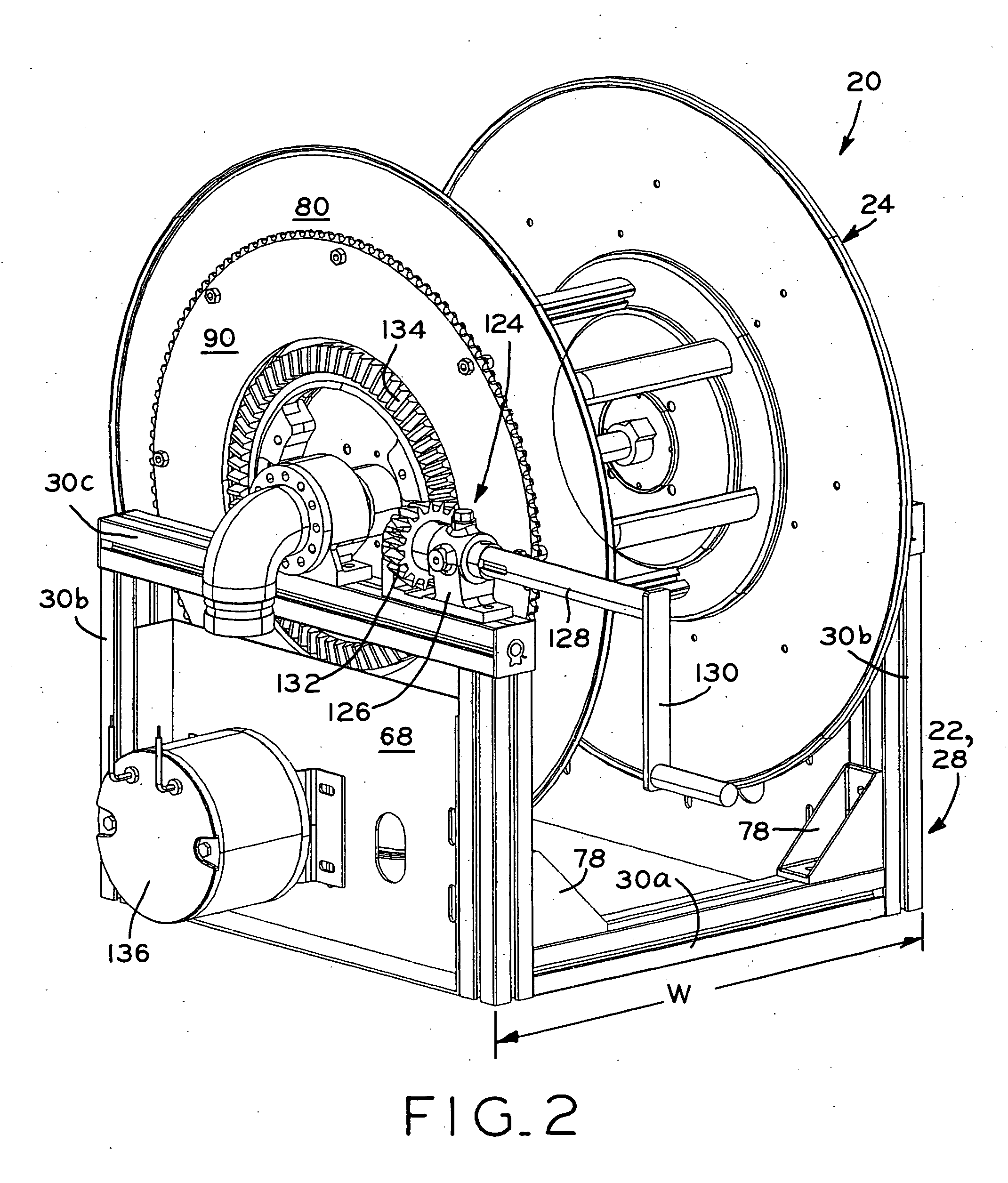

[0037] Referring first to FIGS. 1 and 2, a exemplary reel 20 in accordance with the present invention is shown in the form of a hose reel. Although reel 20 is described below as a hose reel for use in storing a hose 26, it should be understood that the reels 20 according to the present invention may also be used with electrical cords, ropes, cables, or other elongate items in a variety of different applications. Hose reel 20 generally includes base assembly 22 and spool assembly 24 rotatably mounted to base assembly 22, with spool assembly 24 holding a hose 26 or other elongate item wound thereon.

[0038] Referring to FIG. 3, base assembly 22 generally includes base frame 28 formed of a plurality of frame components 30 connected to one another as described below. Frame components 30 may be formed as extrusions, such as aluminum extrusions, for example. Alternatively, frame components 30 may be formed from a rigid plastic via an injection molded or an extrusion process. Base frame 28 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com