Full automatic hydraulic flash butt welding method of metal circular ring chain and apparatus thereof

A metal ring and flash butt welding technology, which is applied in auxiliary devices, metal processing, metal processing equipment, etc., can solve the problems of high labor intensity, high cam manufacturing requirements, wear and other problems, and achieve the reduction of labor intensity and high-quality excision welding. Edges and burrs, the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

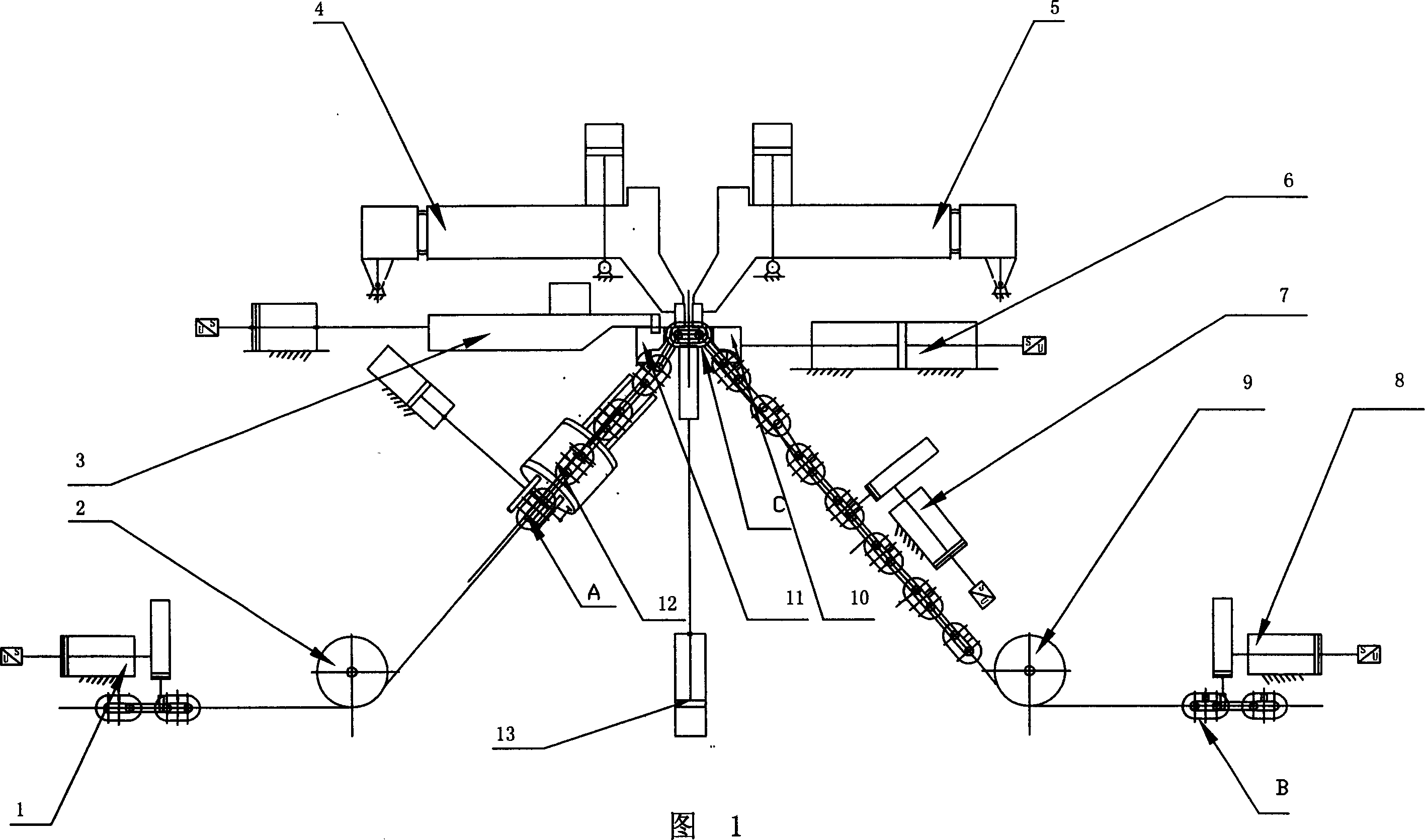

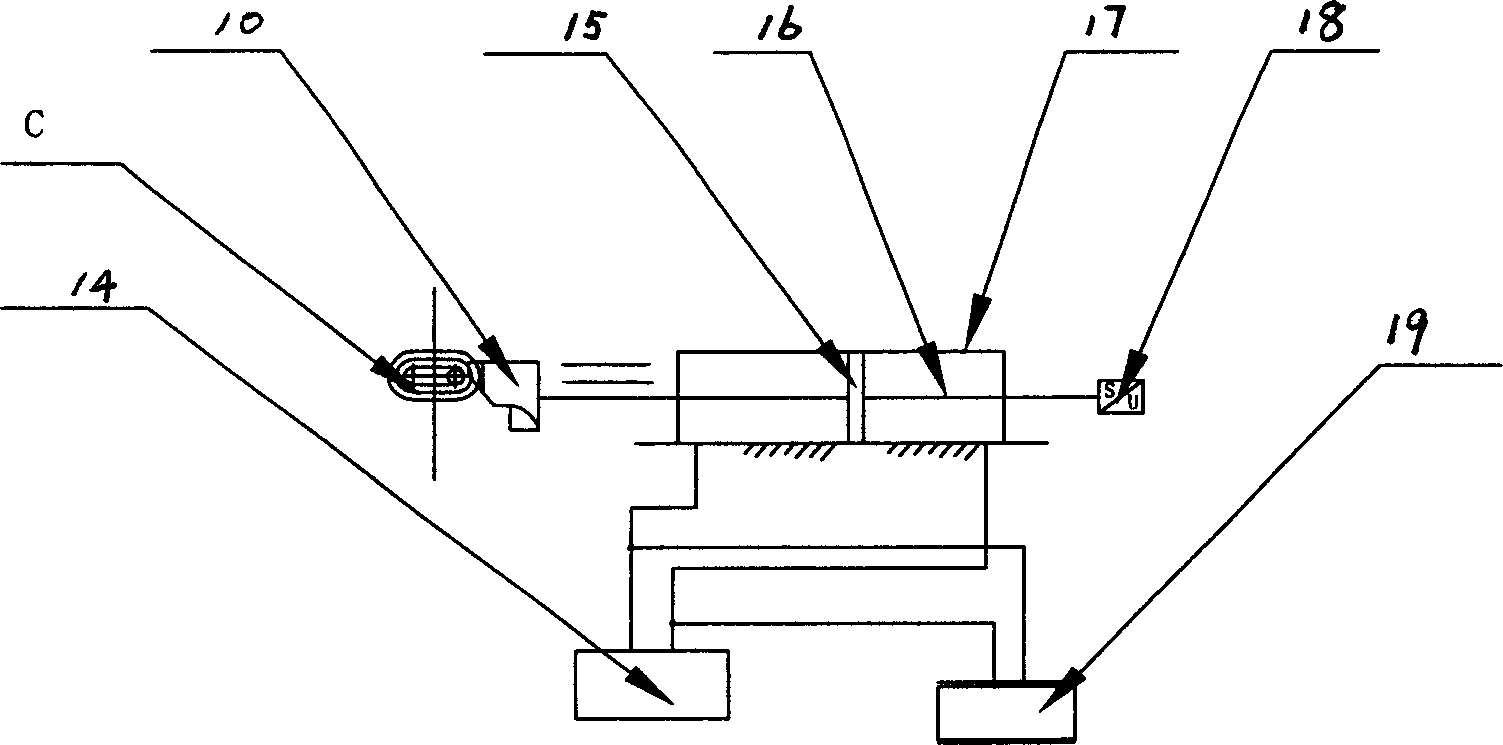

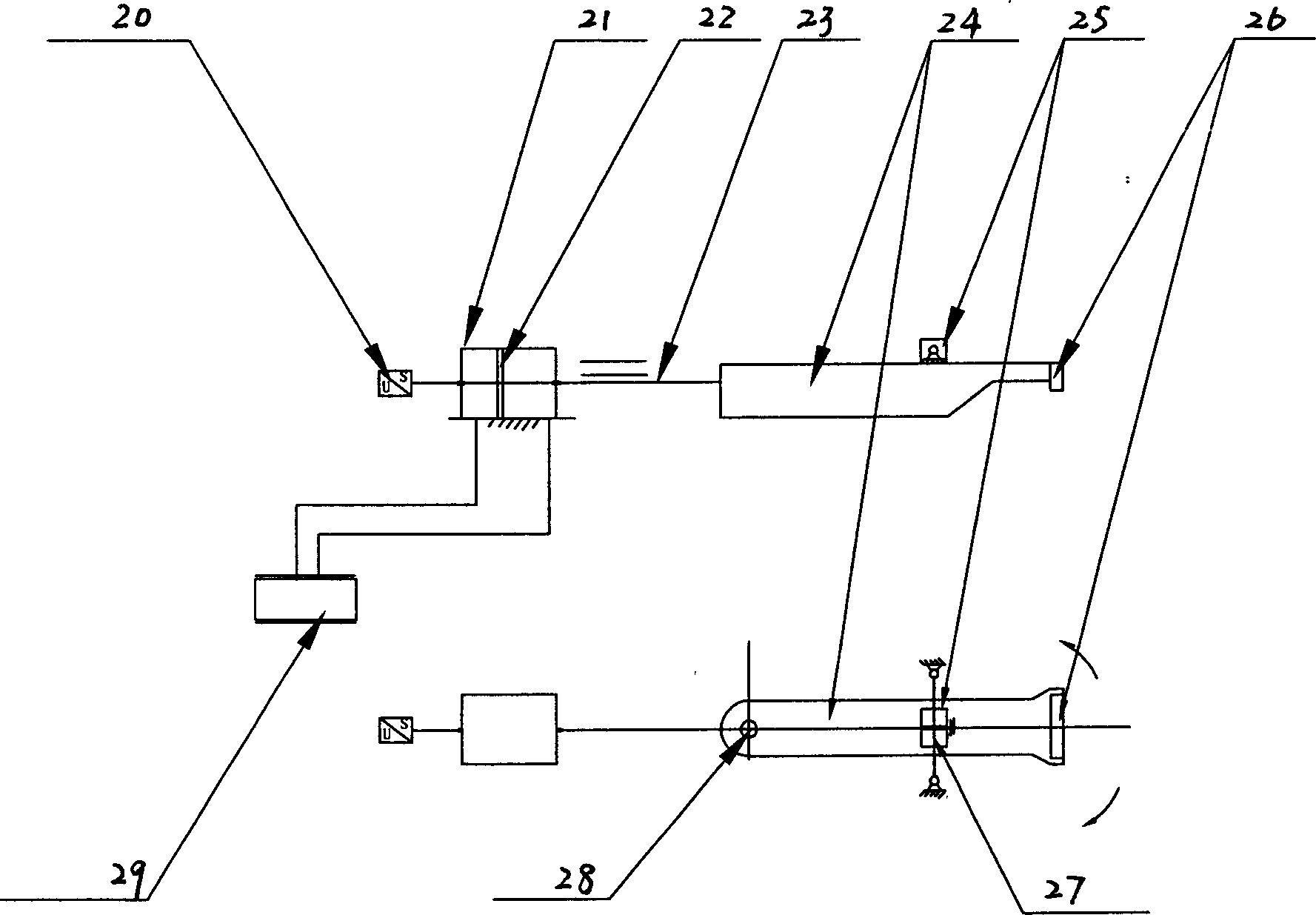

[0023] Shown in Fig. 1 is the structural diagram of the full-automatic full-hydraulic link flash butt welding machine of the present invention. This equipment consists of the following devices: 1 left auxiliary conveying mechanism, 2 left tensioning wheel, 3 hydraulic pressure removal device, 4 left electrode head device, 5 right electrode head device, 6 hydraulic upsetting device, 7 main conveying mechanism, 8 Right auxiliary conveying mechanism, 9 right tensioning wheel, 10 right upsetting cylinder seat, 11 left fixed upsetting steel seat, 12 rotating tube mechanism, 13 lifter mechanism.

[0024] A conveying mechanism for conveying the chain is set on the traveling route of the chain; at the welding position of the welded link C of the chain, there is a hydraulic upsetting device 6 for clamping the welded link C, and a hydraulic upsetting device 6 for welding the welded link C The left and right electrode head devices 4, 5 at the open end of the open end, and the hydraulic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com