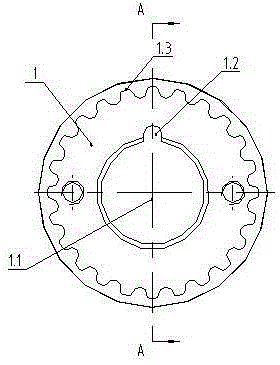

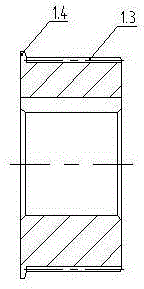

Timing belt wheel for battery electric vehicle engine crankshaft and manufacturing method of timing belt wheel

A pure electric vehicle, timing pulley technology, applied in belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problems of short service life, poor tooth strength, easy failure, etc. The effect of abrasiveness, improving strength and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] By weight, nickel powder 1.75, molybdenum powder 0.5, copper powder 1.5, chromium powder 1.7, manganese powder 1.0, graphite powder 0.8, cerium dioxide 0.2, stearic acid Zinc 0.05%, the rest is iron powder, the sum of each component is 100%; the corresponding process is green density 7.5g / cm3, sintering temperature 1200-1240℃, without tempering treatment.

[0034] After testing, the yield strength of the prepared powder metallurgy alloy is 575MPa, the tensile strength reaches 955MPa, the hardness is 98HRB, and the impact toughness is 31.3J / cm 2 .

Embodiment 2

[0036] The chromium and part of iron in the formula of Example 1 are achieved by adding fine particle Cr-Fe alloy powder with an average particle size of 4.65 μm to achieve the weight ratio.

[0037] After testing, the tensile strength of the prepared powder metallurgy alloy reaches 1212MPa, and the hardness is 31HRC.

Embodiment 3

[0039] By weight, nickel powder 1.75, molybdenum powder 0.5, copper powder 1.5, chromium powder 1.7, manganese powder 1.0, graphite powder 0.8, cerium dioxide 0.2, stearic acid Zinc 0.05%, molybdenum disulfide 0.5%, rare earth element La 0.6%, the rest is iron powder, the sum of each component is 100%; the corresponding process is green density 7.5g / cm 3 , Sintering temperature 1200-1240 ℃, without tempering treatment.

[0040] After testing, the yield strength of the prepared powder metallurgy alloy is 578MPa, the tensile strength reaches 962MPa, the hardness is 80-85HRA, and the impact toughness is 58J / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com