Single lay steel cord for elastomer reinforcement

A technology of elastomers and steel ropes, which is applied in the field of single-twist steel ropes reinforced with elastomers, and can solve problems such as sequential fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

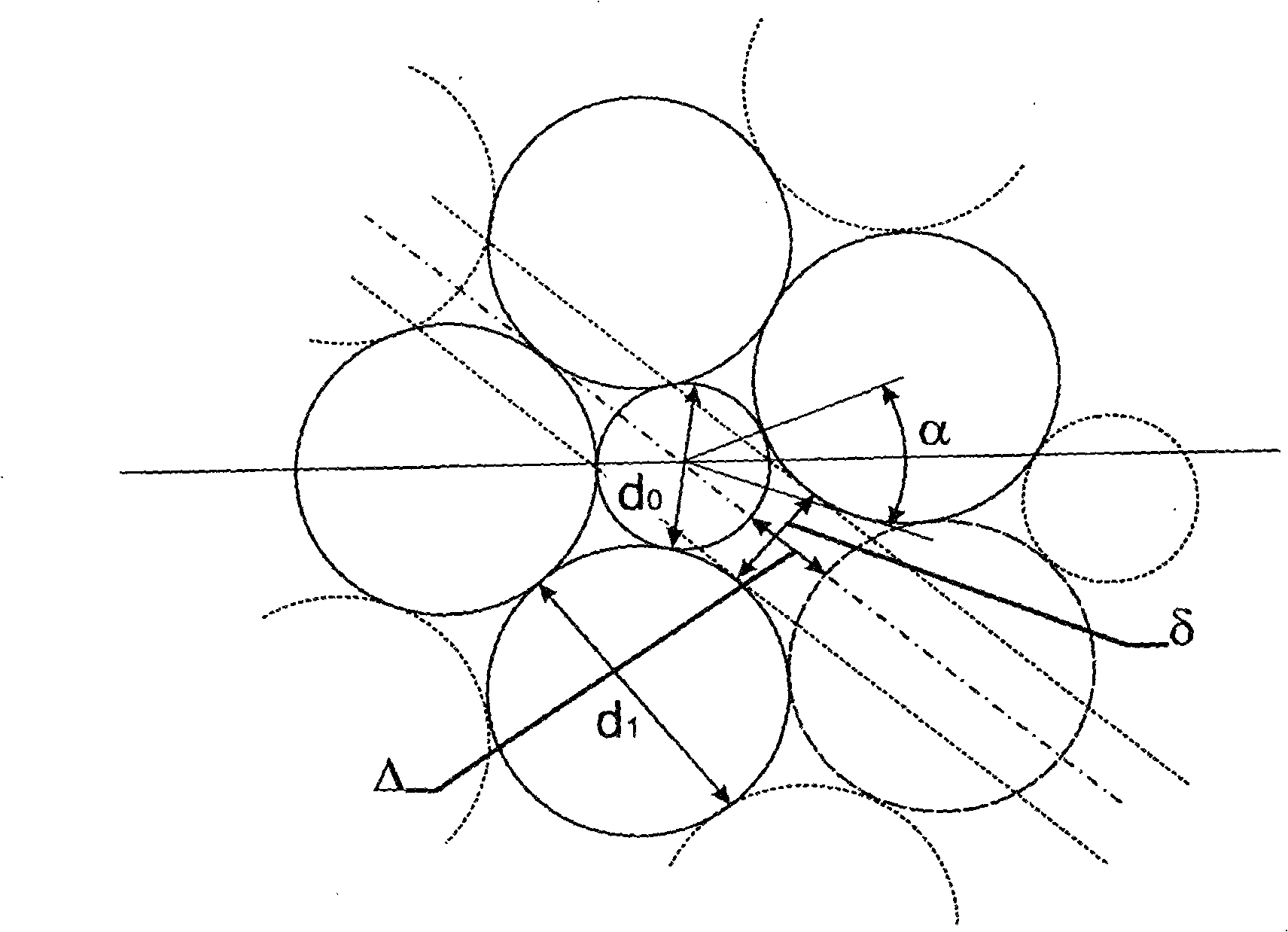

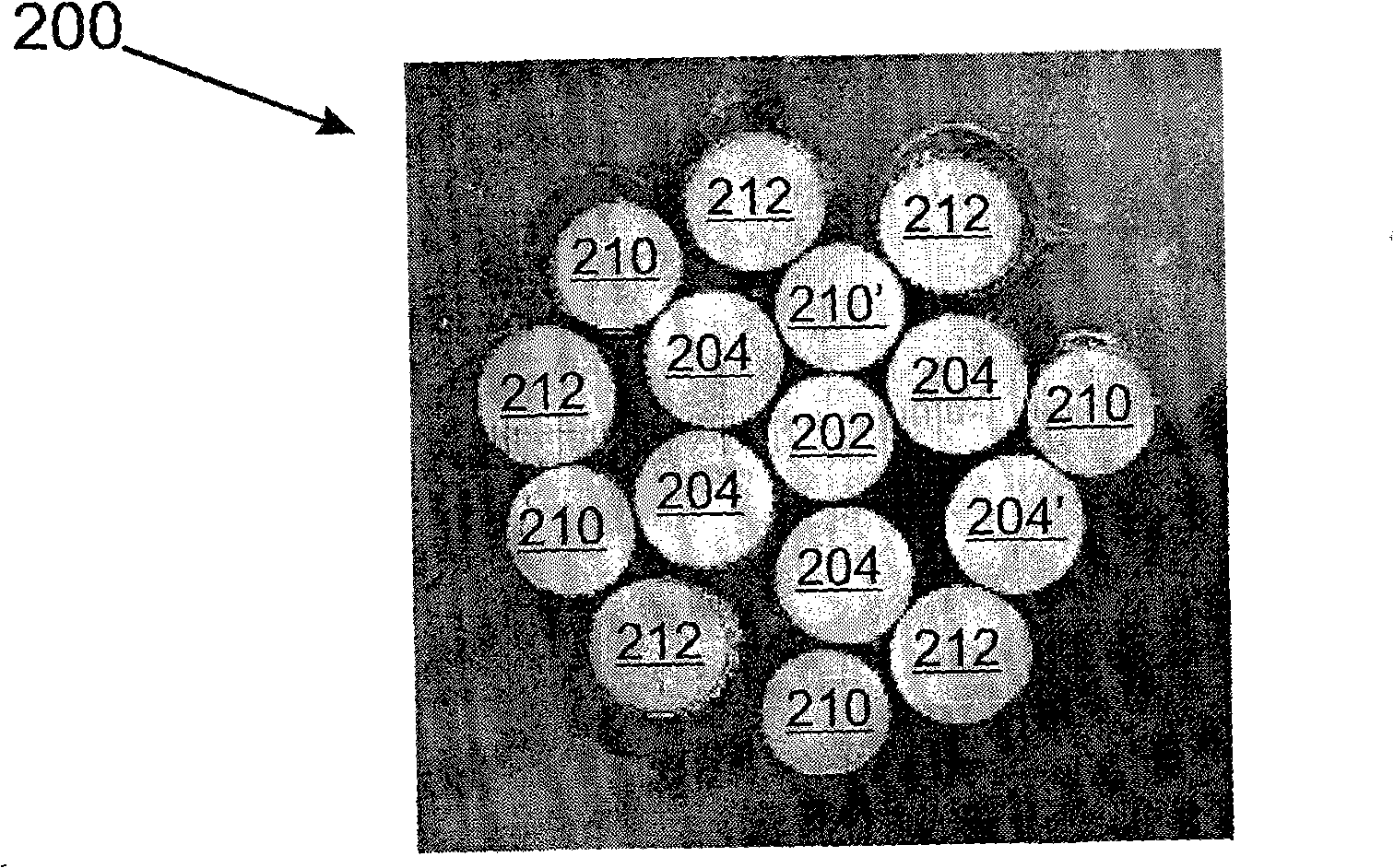

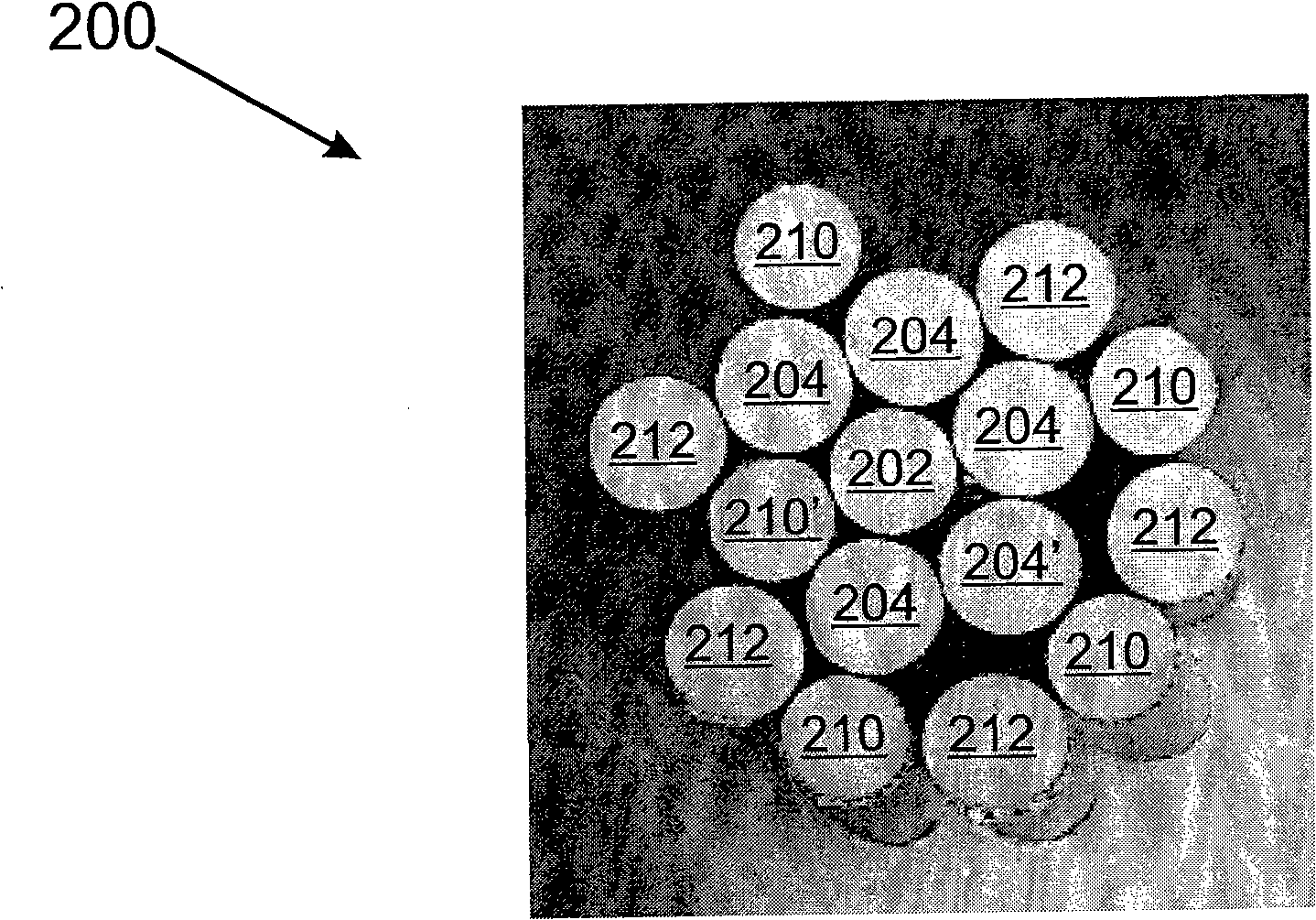

[0049] The original scheme for providing a low-cost alternative is to utilize 1|3×N-type constructions, such as d 0 +(5×d 1 |5×d 2 |5×d 3 ), as described in EP 1474566, where the core filament diameter d 0 small enough to be located with diameter d 1 The center of the 5 first-layer filaments. with diameter d 2 and d 3The filaments form the second layer surrounding the first layer. The filaments between the brackets are assembled together with a single twist in one operation. A vertical bar "|" separates filaments that lie on different rings relative to the center of the circle when "regularly arranged". A "regular" arrangement means that the centers of the filaments of the first layer lie on a regular "N-gon", where N is the number of filaments in the layer. The filaments of the second layer are adjacent to the two filaments in the first layer in the slit formed by the filaments of the first layer, and are arranged according to the circumferential direction when they ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com