Electric timing belt wheel

A synchronous pulley and electric technology, applied in the direction of electric components, belts/chains/gears, electromechanical devices, etc., can solve the problems of uneven appearance of pulleys, low processing efficiency, complicated procedures, etc., to promote automation and intelligence, Improve the tightness of the connection and keep it clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

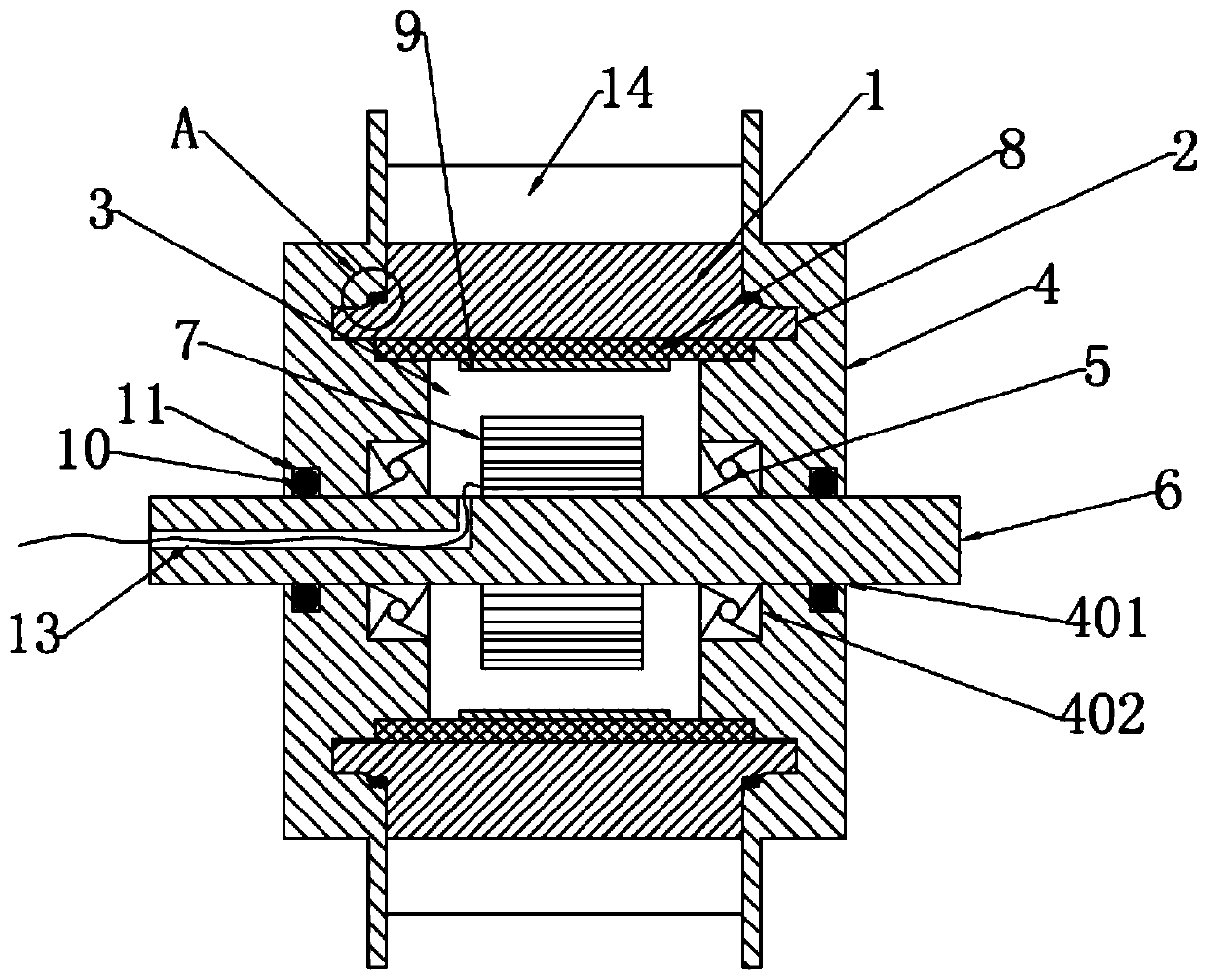

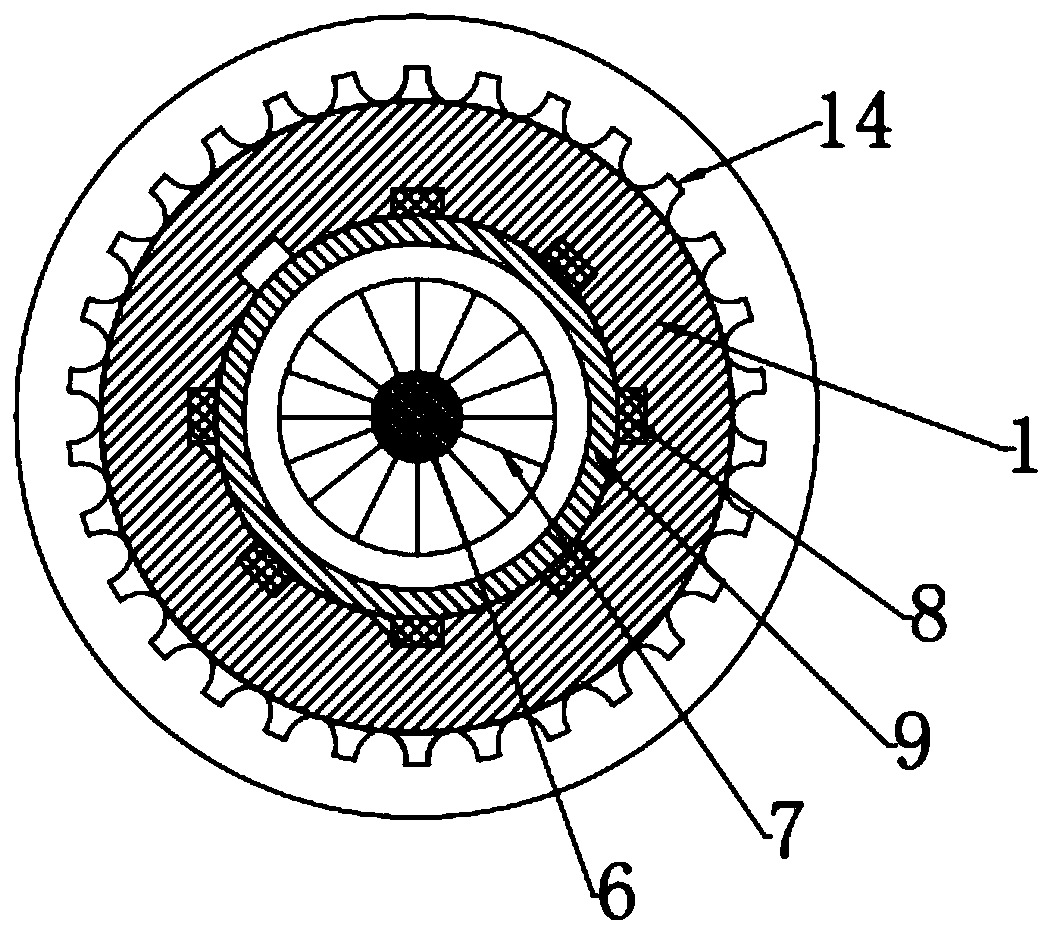

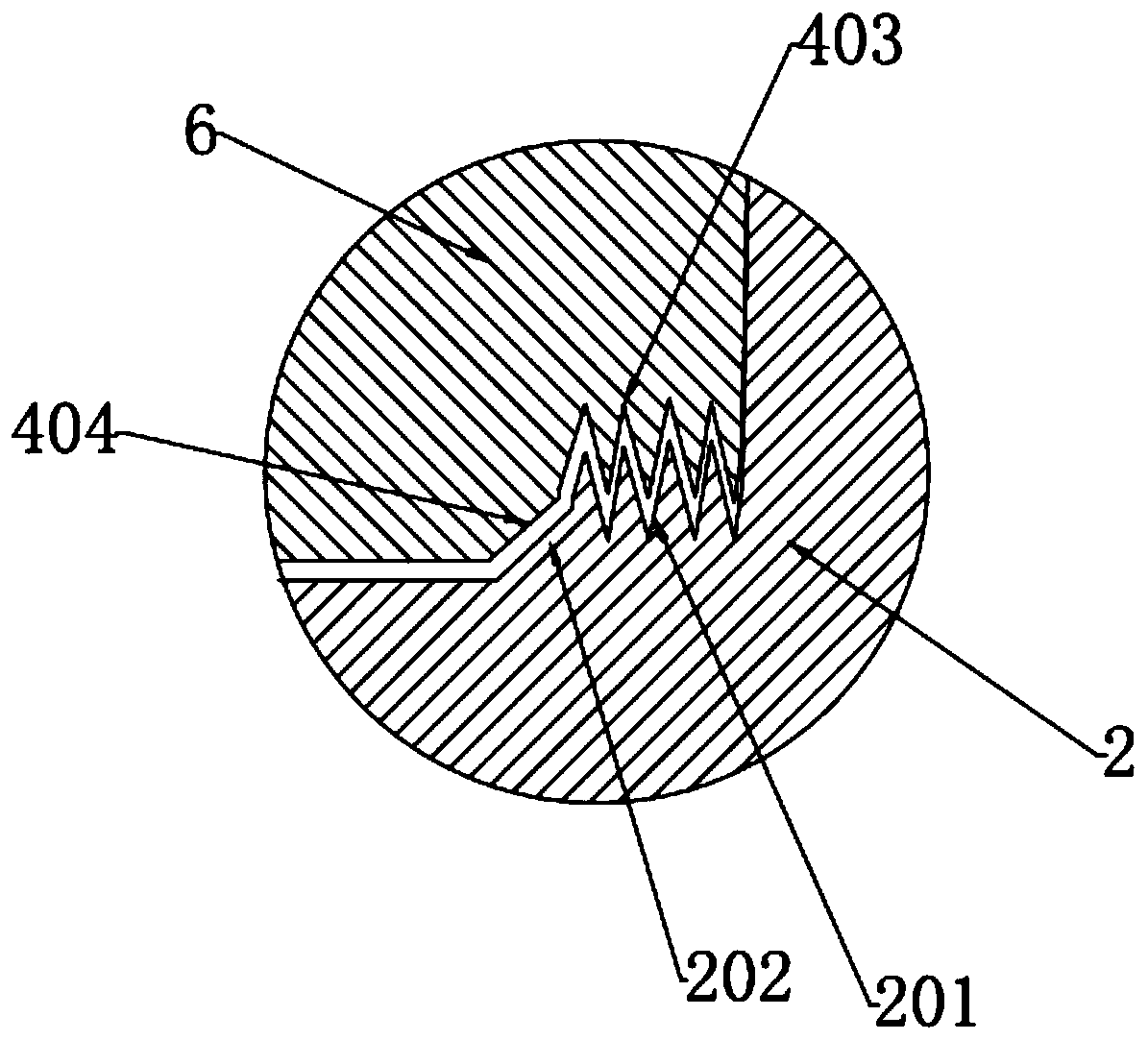

[0018] An electric synchronous pulley, comprising a pulley body 1 with protrusions 2 at both ends, the axis of the pulley body 1 and the protrusions 2 at both ends is provided with the pulley body 1 and the protrusions 2 at both ends The central round hole 3 of the said protrusion 2 is connected with an end cover 4, the axis line of the end cover 4 is provided with a shaft hole 401 communicating with the central round hole 3, and the end cover 4 is close to the pulley body 1 A bearing installation hole 402 is provided on one side coaxially with the shaft hole 401, and a bearing 5 is installed in the bearing installation hole 402, and a fixed shaft 6 is coaxially installed on the two end covers 4 through the bearing 5, and the fixed shaft 6 is located in the center A stator coil 7 is installed inside the round hole 3 , and a rotor yoke 8 is provided inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com