Novel single pillar structure and mounting method thereof

An installation method, a single-column technology, applied in the field of marine engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

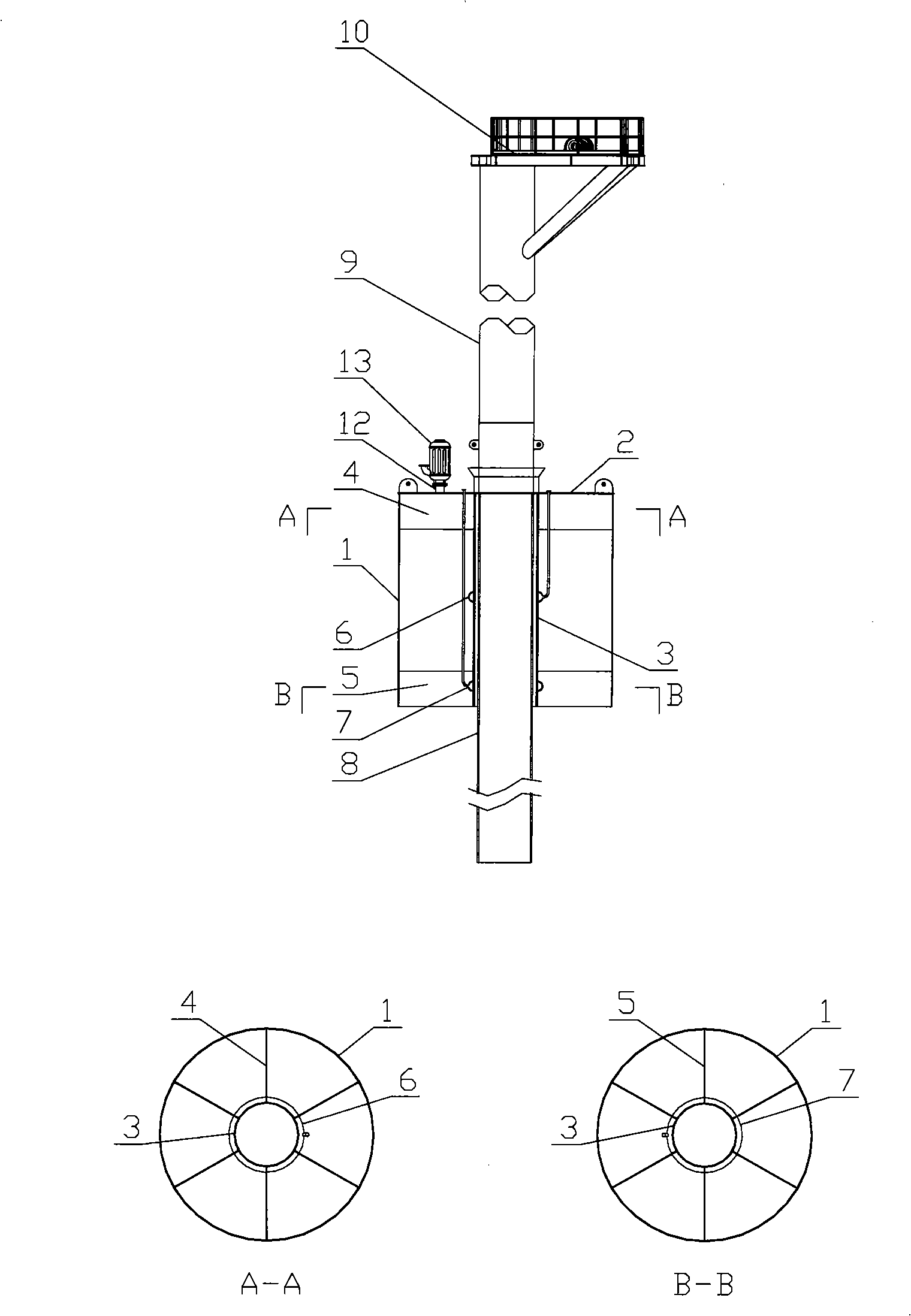

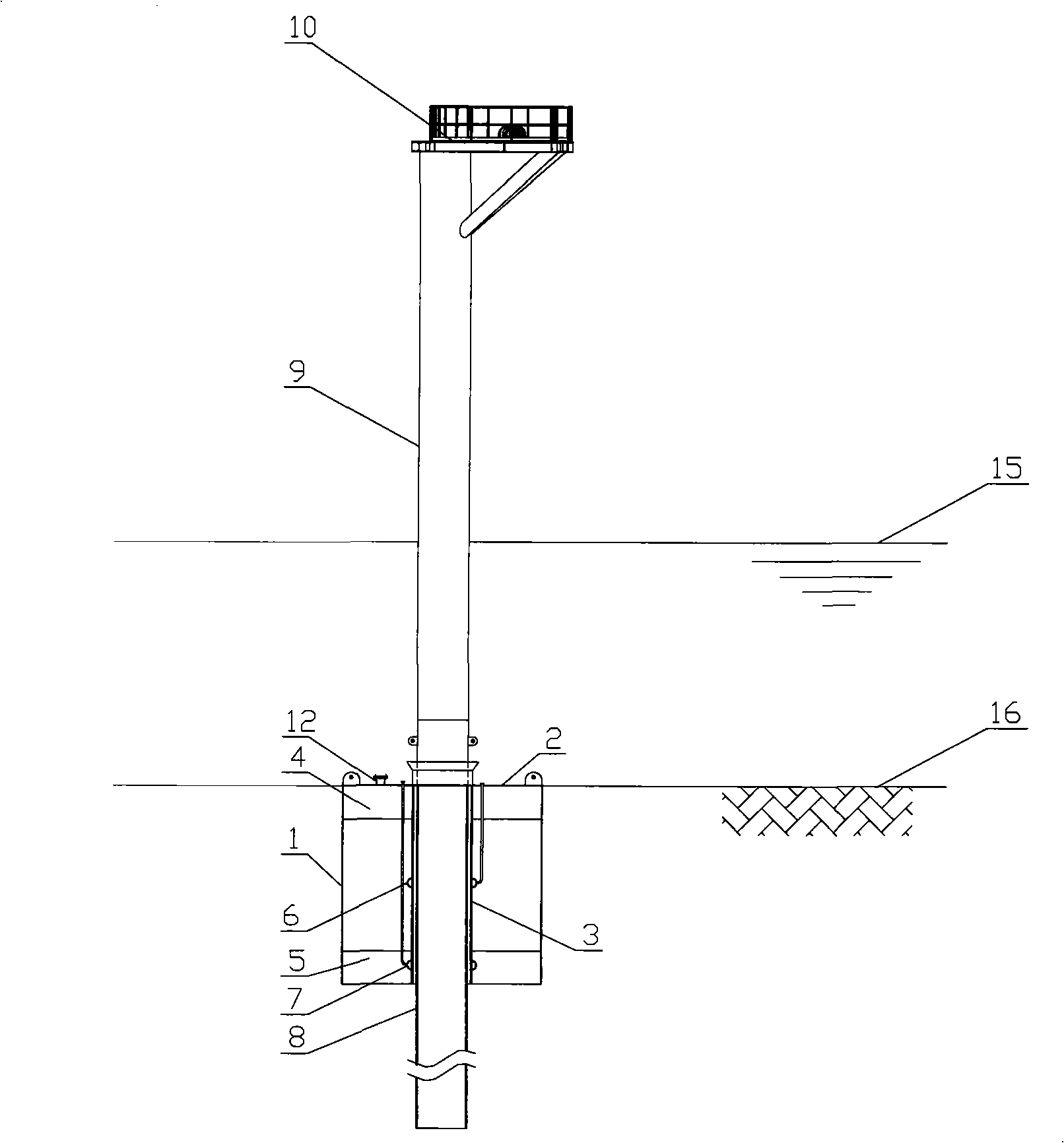

[0010] The new single-column structure see figure 1 , consisting of a cylinder body 1, a top cover 2, a central guide cylinder 3, an upper rib 4, a lower rib 5, a grouting spray ring 6, a mud cleaning ring 7, driven piles 8, a central column 9, and a small platform 10 Composed of pump port 12, the driven pile 8 is located in the center guide cylinder 3, the central column 9 and the small platform 10 are connected with the driven pile 8; the top surface of the top cover 2 is provided with a pump port 12, and a submersible pump 13 or a pneumatic pump is installed above it. Pump.

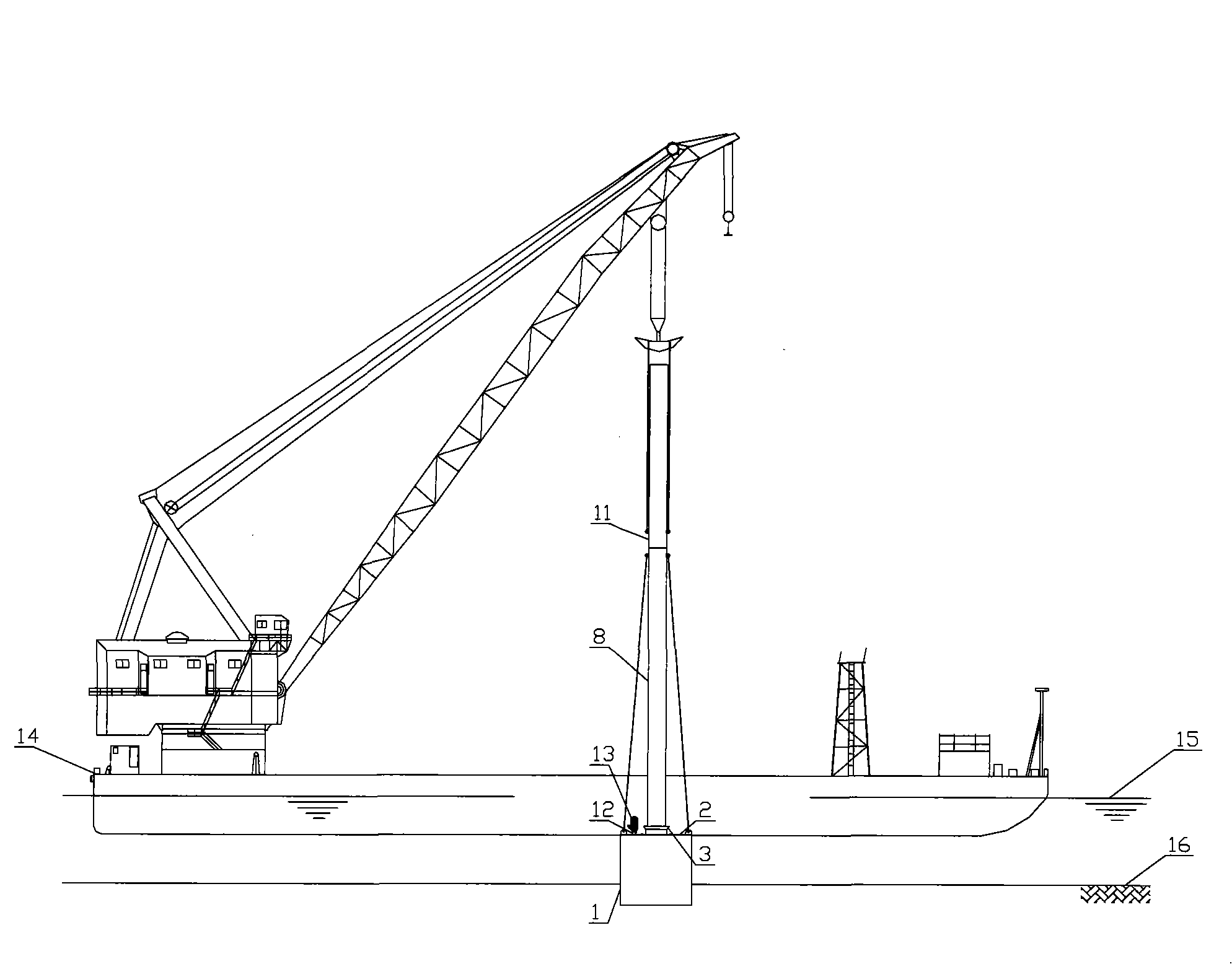

[0011] The new single-column structure is integrally hoisted into the water and released figure 2 At this moment, the suction pile, the driving pile 8 and the sending pile 11 and the submersible pump 13 are lowered to the seabed mud surface by the floating crane 14, and the initial mud entry of the suction pile and the driving pile 8 foundation reaches the sealing condition by dead weight.

[0012] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com