Large-diameter pile base reinforcing steel bar in-hole layering and bundling construction method

A construction method and reinforcement hole technology, which can be used in infrastructure engineering, sheet pile walls, building structures, etc., can solve problems such as hidden safety hazards, difficulty in construction of large-diameter steel cages, and difficulty in hoisting, so as to control the hoisting weight and facilitate the The effect of setting up an operation stand and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

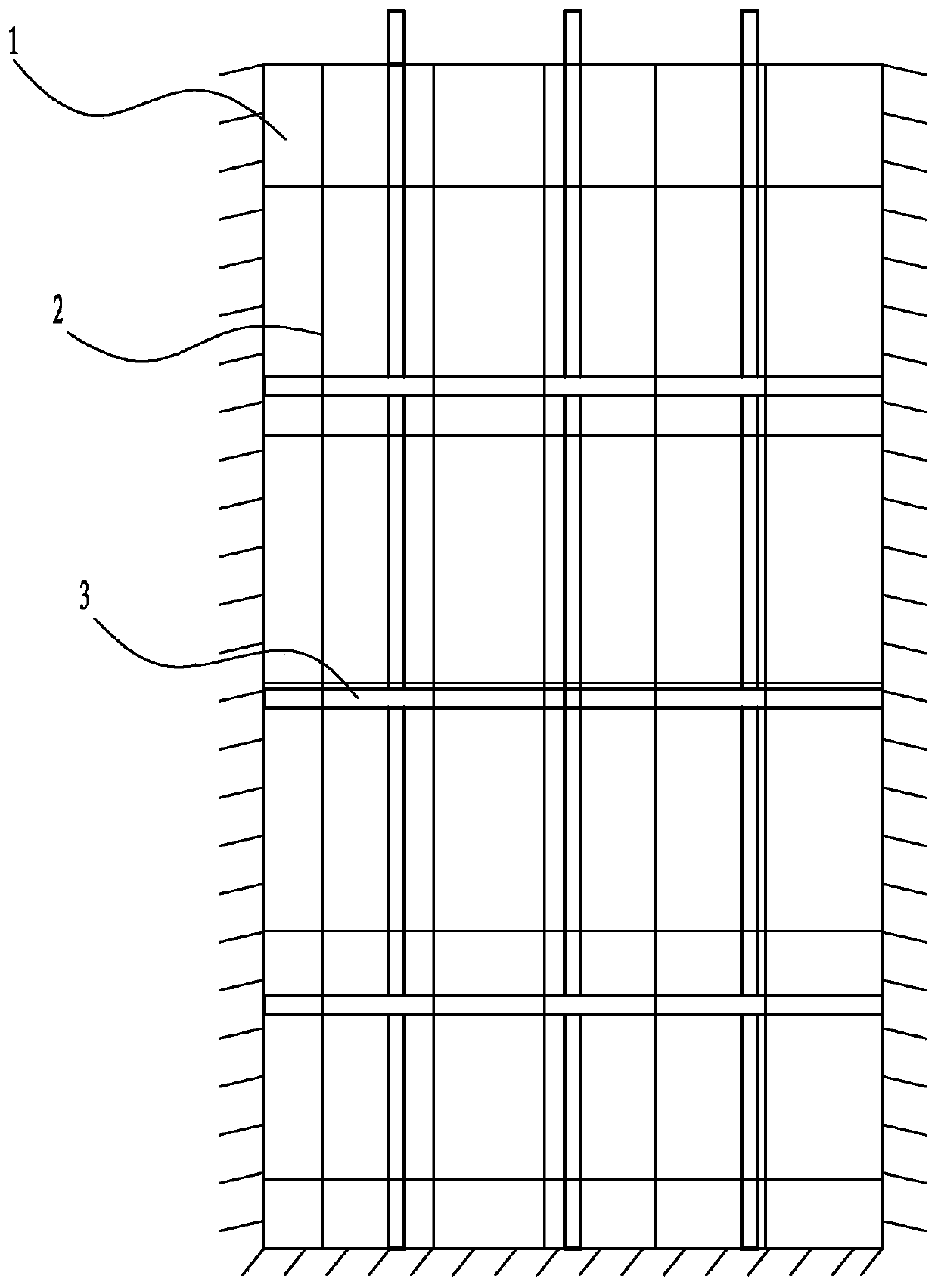

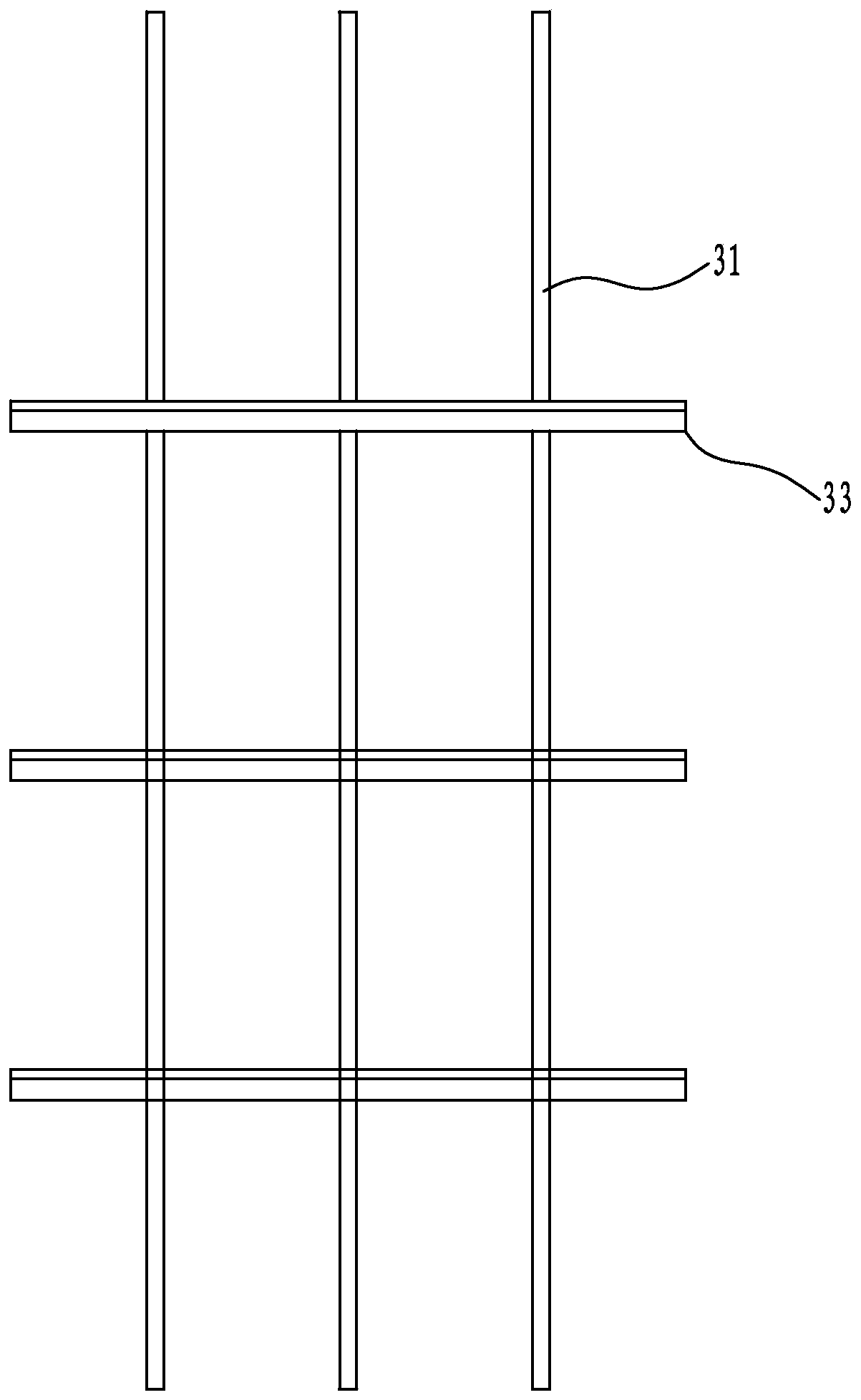

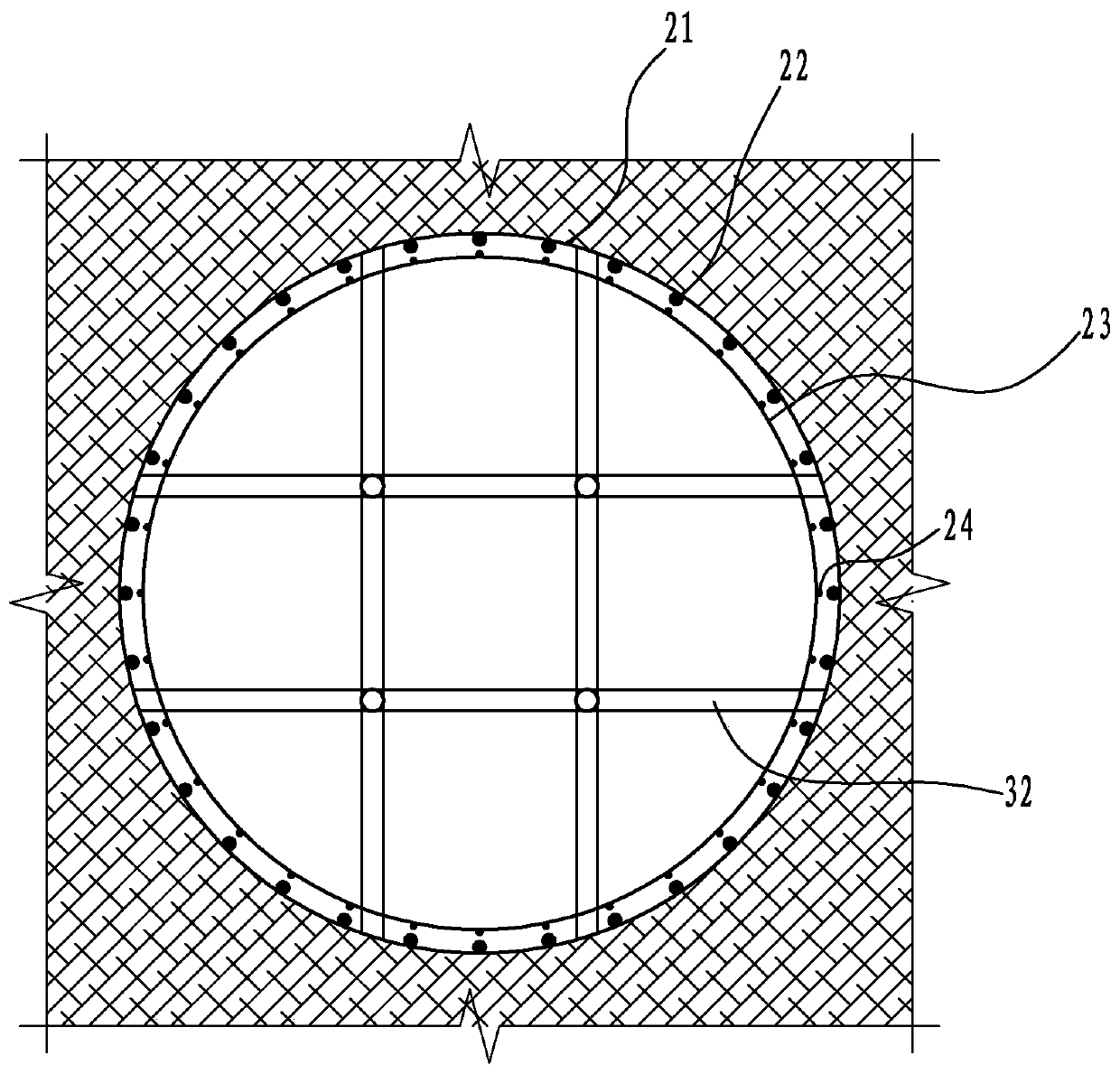

[0028] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a layered binding construction method in a large-diameter pile foundation reinforcement hole disclosed by the present invention specifically includes the following construction steps:

[0029] S1: Deepen the construction drawing. According to the reinforcement diagram of the pile foundation and the site construction conditions, the reinforcement arrangement of the pile foundation is deepened, and the reinforcement cage 2 and the operation frame 3 are designed according to the size of the pile diameter and the arrangement and spacing of the reinforcement. For each type A deepened drawing of reinforcement cage 2 and operating frame 3 and a deepened diagram of reinforcement arrangement shall be issued for the piles. The arrangement of the operation frame 3 is determined according to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com