Prefabricated T-beam and construction method

A prefabricated assembly and construction method technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of difficult quality assurance and long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

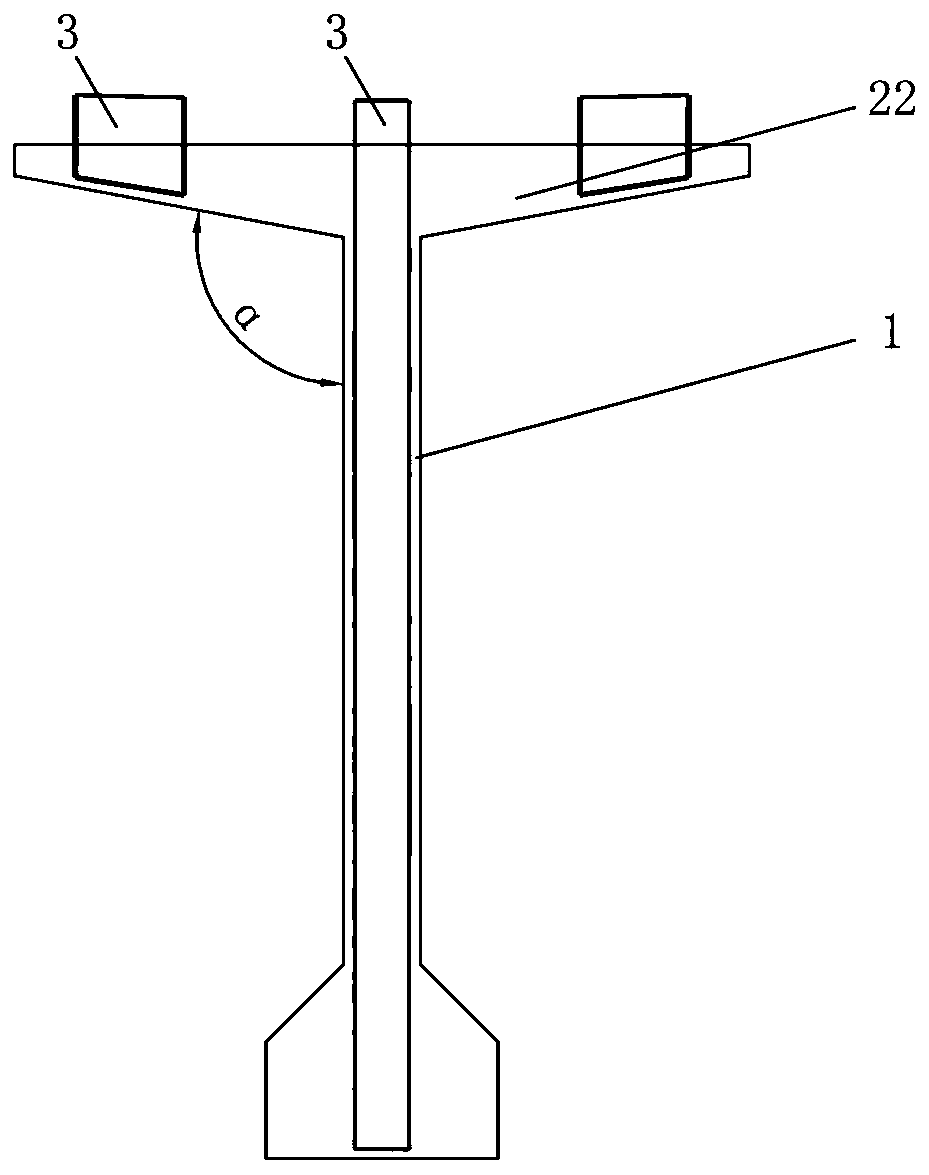

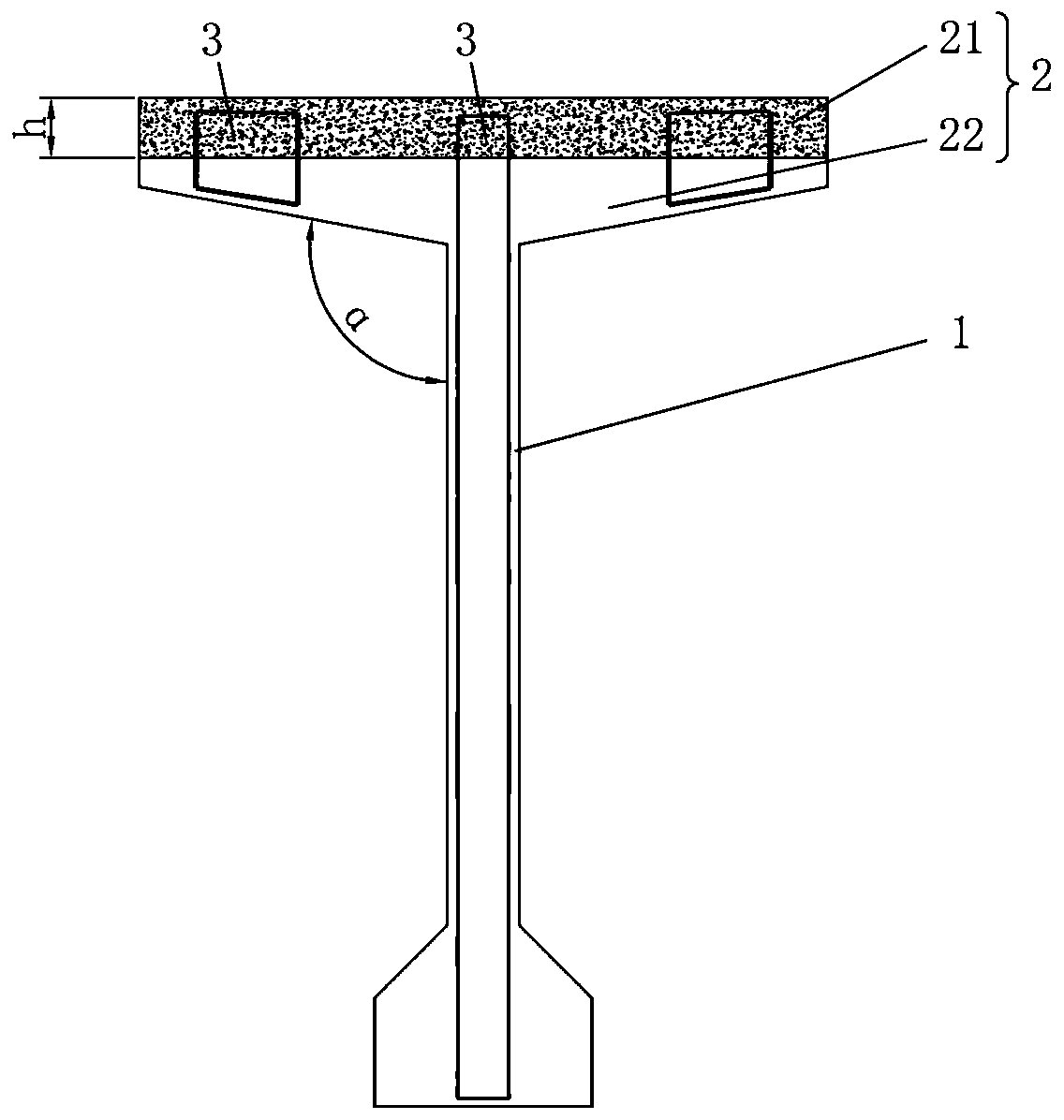

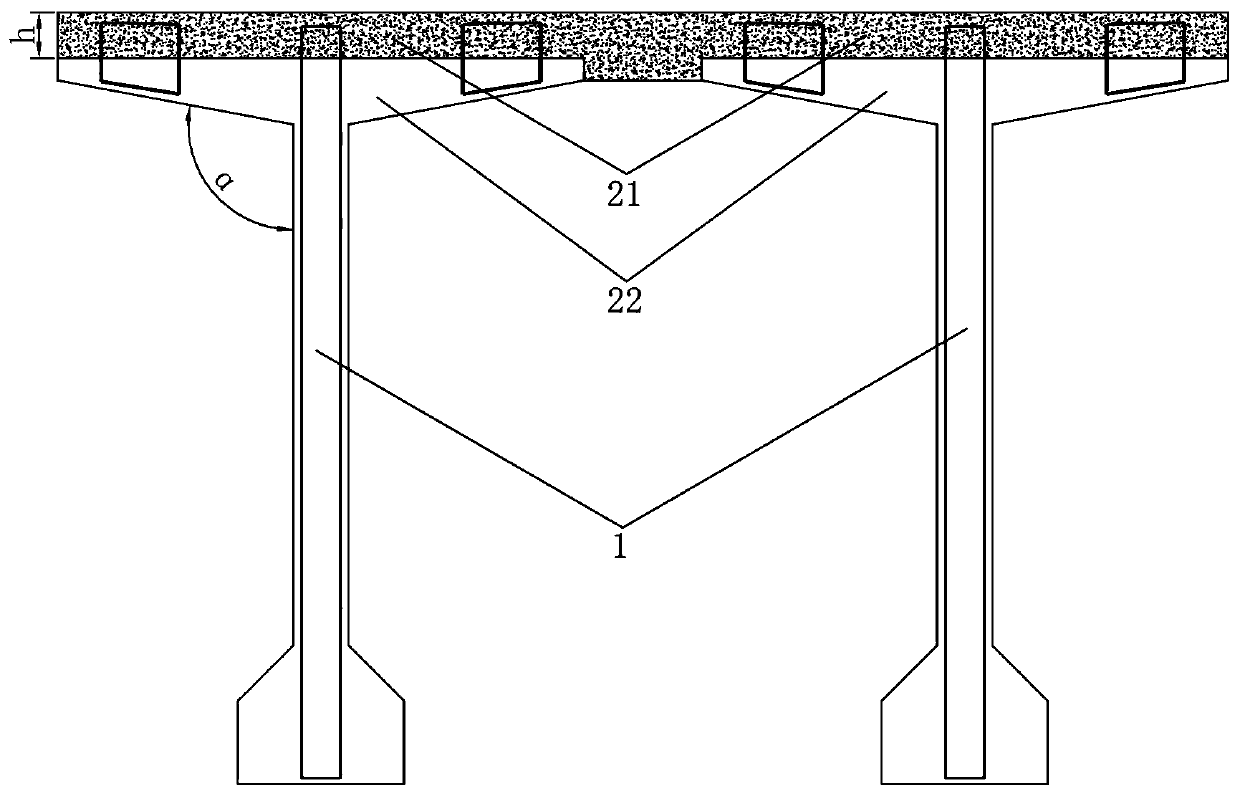

[0033] like figure 1 and figure 2 As shown, the prefabricated T-beam of this embodiment includes a T-beam unit, the T-beam unit includes a beam rib 1 and a wing plate 2, and the wing plate 2 includes a wing top plate 21 and two wing lower plates 22, wherein the two wing lower plates 22 is the same as the current T-beam system. It is set on both sides of the top of the beam rib 1 and prefabricated with the beam rib 1 as a whole. The wing top plate 21 is laid and poured on the wing lower plate after the beam rib 1 and the wing lower plate 22 are prefabricated. 22 and the top surface of the beam rib 1, and then the lower wing plate 22 and the beam rib 1 are fixed and stressed together.

[0034] This arrangement method can only hoist the beam rib 1 and the lower wing plate 22 during hoisting, and then lay the wing top plate 21 after erection is in place. The hoisting weight is greatly reduced, and the requirements for the bearing capacity of the transportation road are low, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com