Multi-stage green assembling cantilever-type reinforced earth retaining wall

A cantilever type, reinforced soil technology, applied in construction, artificial island, infrastructure engineering, etc., can solve the problems of large bending moment and shear force of the wall body, large horizontal displacement of the wall top, cumbersome construction process, etc. The effect of bending moment and shear force, reducing horizontal displacement, and improving slope stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

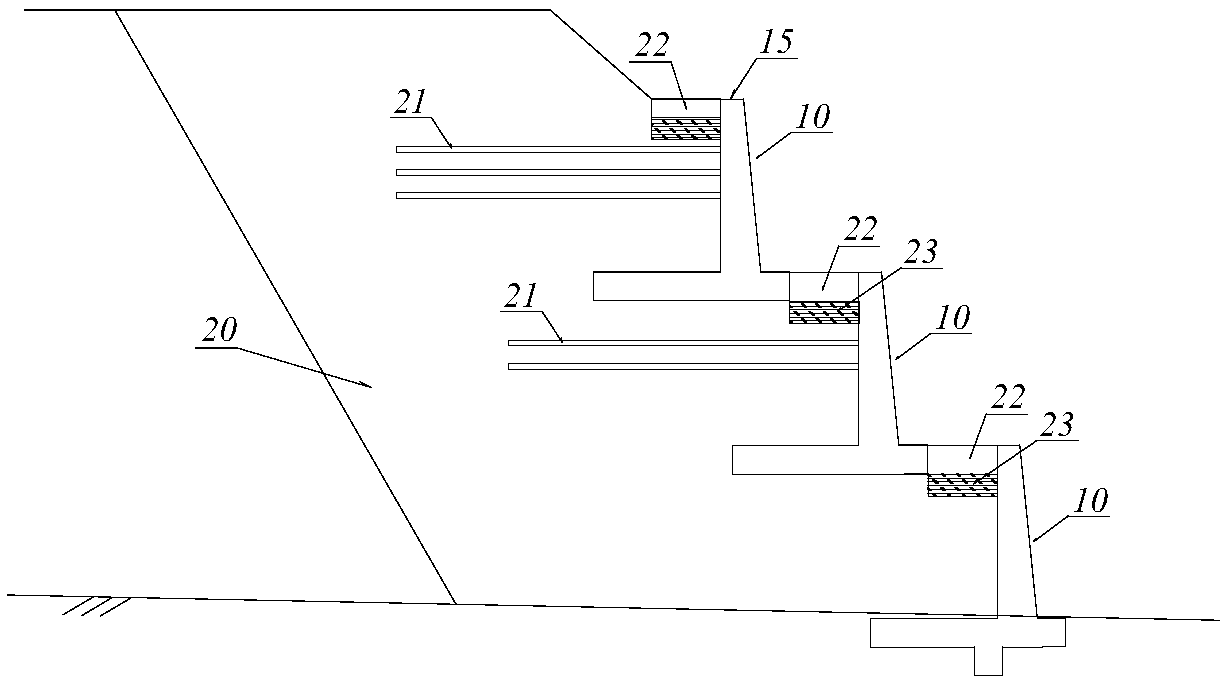

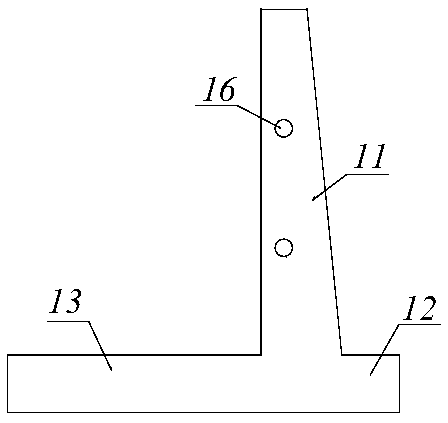

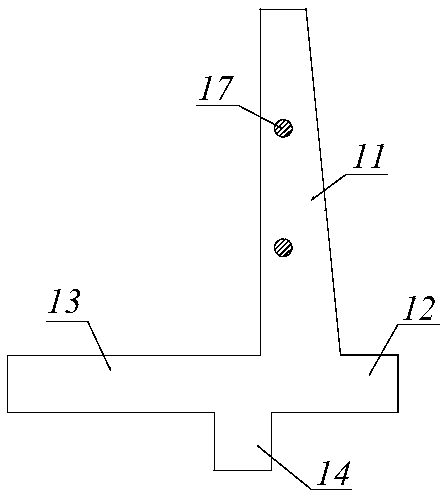

[0022] refer to figure 1 , the multi-stage green assembled cantilever reinforced soil retaining wall of the present invention, the cantilever reinforced soil retaining wall is arranged step-by-step on the filling soil body 20, and the cantilever reinforced soil retaining wall at all levels is composed of reinforced concrete cantilever type The retaining wall segments 10 are spliced horizontally, between the top of the next cantilever reinforced earth retaining wall and the bottom of the previous group of cantilever reinforced earth retaining walls, the uppermost cantilever reinforced earth retaining wall A step 22 is formed between the top of the top and the slope of the filling soil body 20, and green plants are planted in the step 22 to form a green belt 25. Two adjacent reinforced concrete cantilever retaining wall segments 10 of the same level ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com