Self-moving type recycled block body discharging, mixing and vibrating device

A vibrating device and self-moving technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of full mixing of non-renewable blocks and cast-in-place concrete, laborious opening of drawer-type baffles, and the bearing capacity of formwork. Require high-level problems to achieve the effect of reducing manpower consumption, high degree of automation, and highly targeted blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific measures of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the embodiments of the present invention are not limited thereto.

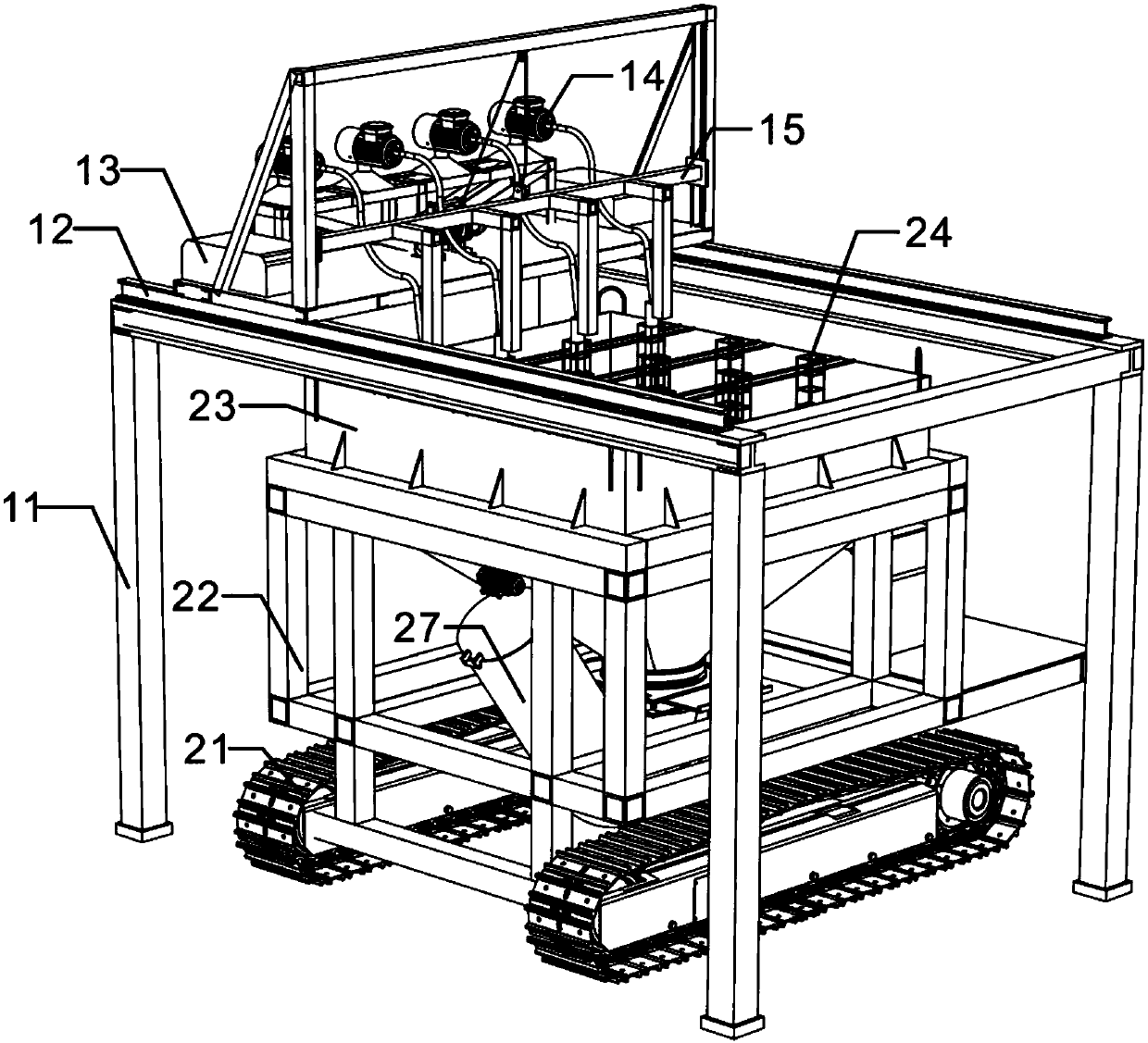

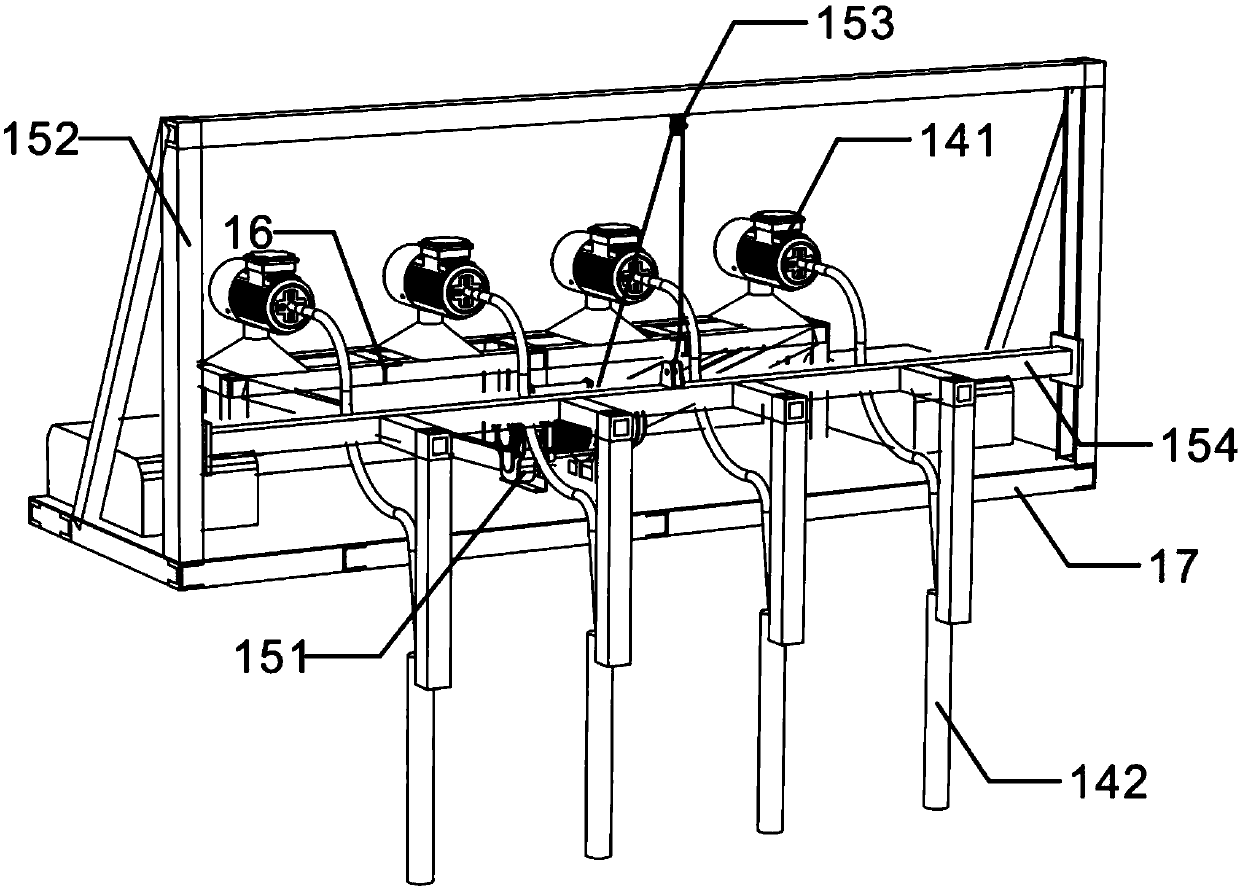

[0032] Such as figure 1 , 2 . As shown in 3, a self-moving regenerative block blanking and mixing vibrating device includes: a vibrating support frame 11, a track 12 arranged in parallel on the top of the vibrating support frame 11, reciprocating along the track 12 Sliding walking trolley 13, some vibrators 14, walking drive system 21, hopper 23 arranged on the walking driving system 21, opening from the top of the hopper 23, horizontally equidistantly arranged on the walking trolley 13 A plurality of vibrating guiding devices 24 extending to the inside of the hopper, and a chute 27 connected to the discharge port of the hopper 23 .

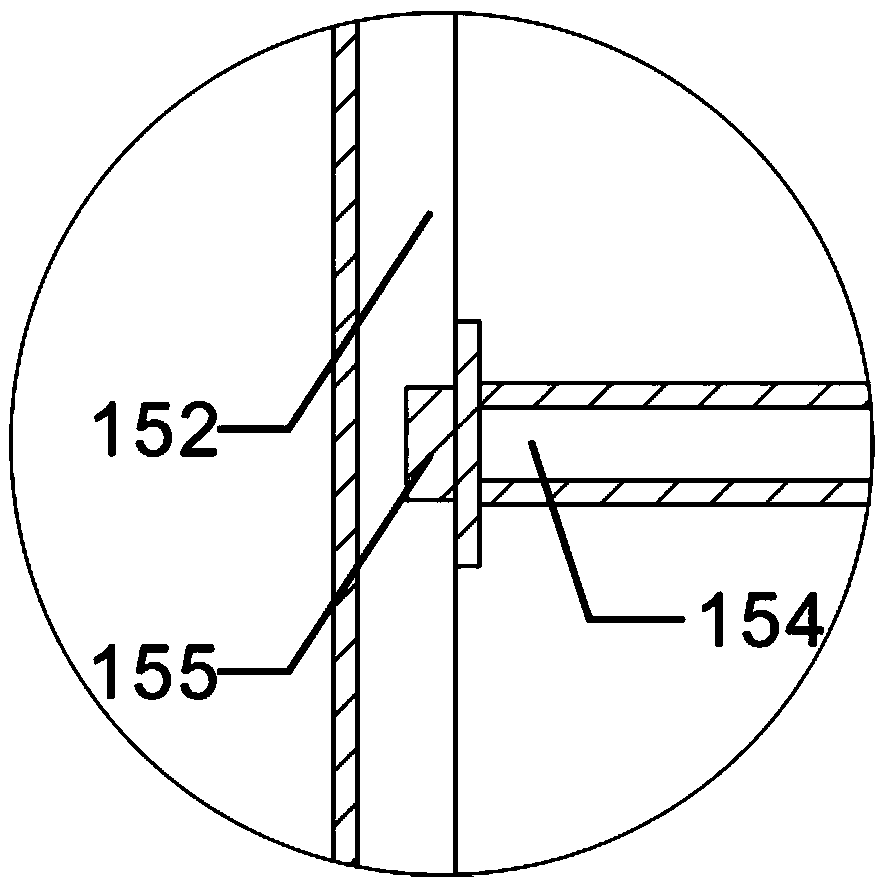

[0033] The walking trolley 13 includes a sliding bottom plate 17 cooperating with the track 12 , a lifting mechanism 15 fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com