Construction method for assemble cargo boom of crawling crane through breaking-off method

The technology of a crawler crane and construction method, which is applied in the directions of crane, transportation and packaging, can solve problems such as the combination of boom sections, and achieve the effect of reducing trimming, reducing damage to the ecological environment and having a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

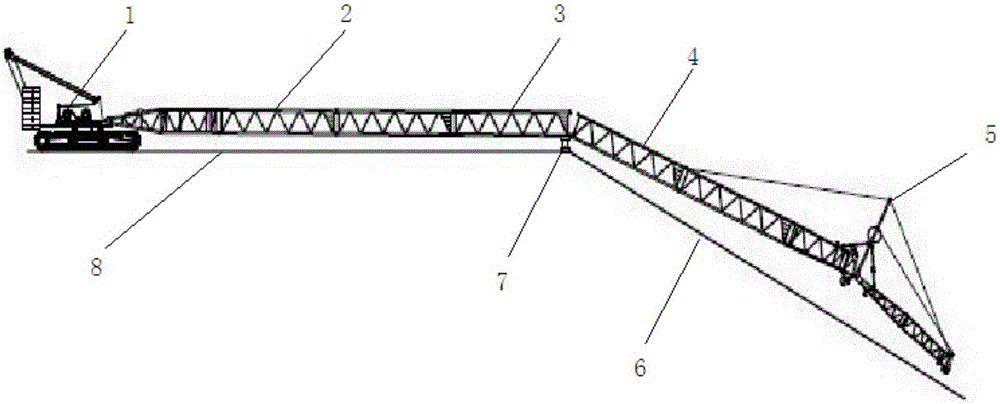

[0031] A construction method using the "breaking method" to combine the boom of a crawler crane is as follows:

[0032] When 8 pairs of booms are combined on the horizontal ground with the same height as the platform where the main engine 1 of the crawler crane is located, each boom section unit 2 is sequentially connected with the upper pin shaft and the lower pin shaft from the root section; when the boom is combined under the ground In the slope position, a support device 7 is placed on the ground adjacent to the downhill position to support the assembled boom unit 2;

[0033] Then the boom section unit 3 at this position and the next boom section unit 4 are only connected to the lower parts of the two boom section units through the lower pin shaft, and then connected successively through the upper pin shaft and the lower pin shaft along the ground slope. down each arm section unit;

[0034] After all the boom section units are assembled and the hook rope 5 is put on, use ...

Embodiment 2

[0038] When the ground is extremely uneven, drive the main engine of the crawler crane to a position with a certain height above the ground, and then use the upper pin shaft and the lower pin shaft to connect each arm section unit sequentially from the root section in the air, when installed to the set position When the boom section unit at this position is connected to the next boom section unit, the lower parts of the two boom section units are only connected through the lower pin shaft, and then the next boom sections are connected sequentially through the upper pin shaft and the lower pin shaft. unit;

[0039] After all the boom section units are assembled, lift the head position of the boom, and gradually lift it to the same level as the boom root section, install the upper pin between the two boom section units at the downhill position The shaft connects the tie rods of the two boom section units;

[0040] After all the installation work is completed, the main hoisting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com