Modular cast-in-place construction method for large-diameter root foundation

A technology of foundation modules and construction methods, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of difficult transportation of prefabricated parts in the construction site, difficulty in sinking caissons, and large hoisting equipment, and achieve light weight and shortened construction period , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Concrete construction among the present embodiment is carried out as follows:

[0029] 1. At the position where the root foundation is set, use a drilling rig to construct a pile hole; the suitable foundation outer diameter is generally 3-7m;

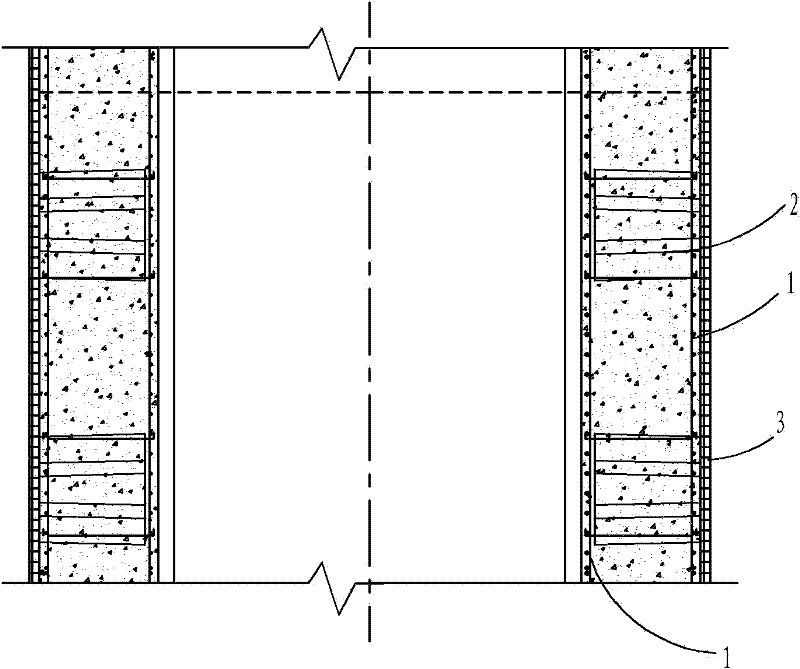

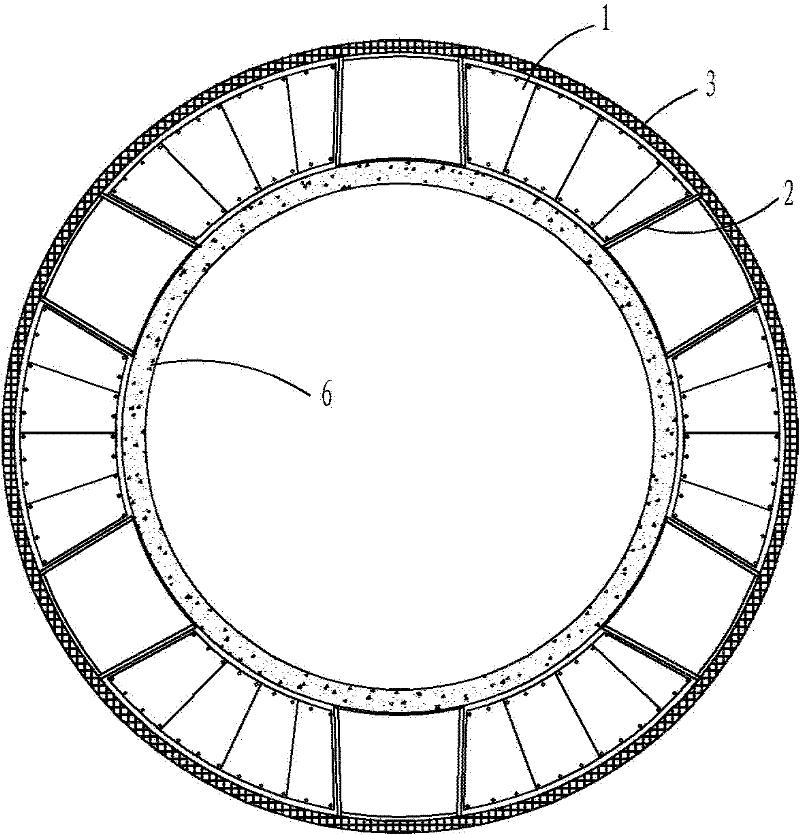

[0030] 2. If figure 1 with figure 2 As shown, the FRP composite structure of each segment is made in sections. The FRP composite structure is to set the root key steel sleeve 2 radially and radially in the double-layer steel cage 1, and wrap the outer steel wire around the outer periphery of the double-layer steel cage 1. Mesh, the distance between the outer steel wire mesh and the outer steel bars of the double-layer steel cage is maintained with a concrete protective layer, and then the FRP layer 3 is formed in the form of winding on the outer periphery of the outer steel wire mesh; the length of each segment of FRP is 6-10m.

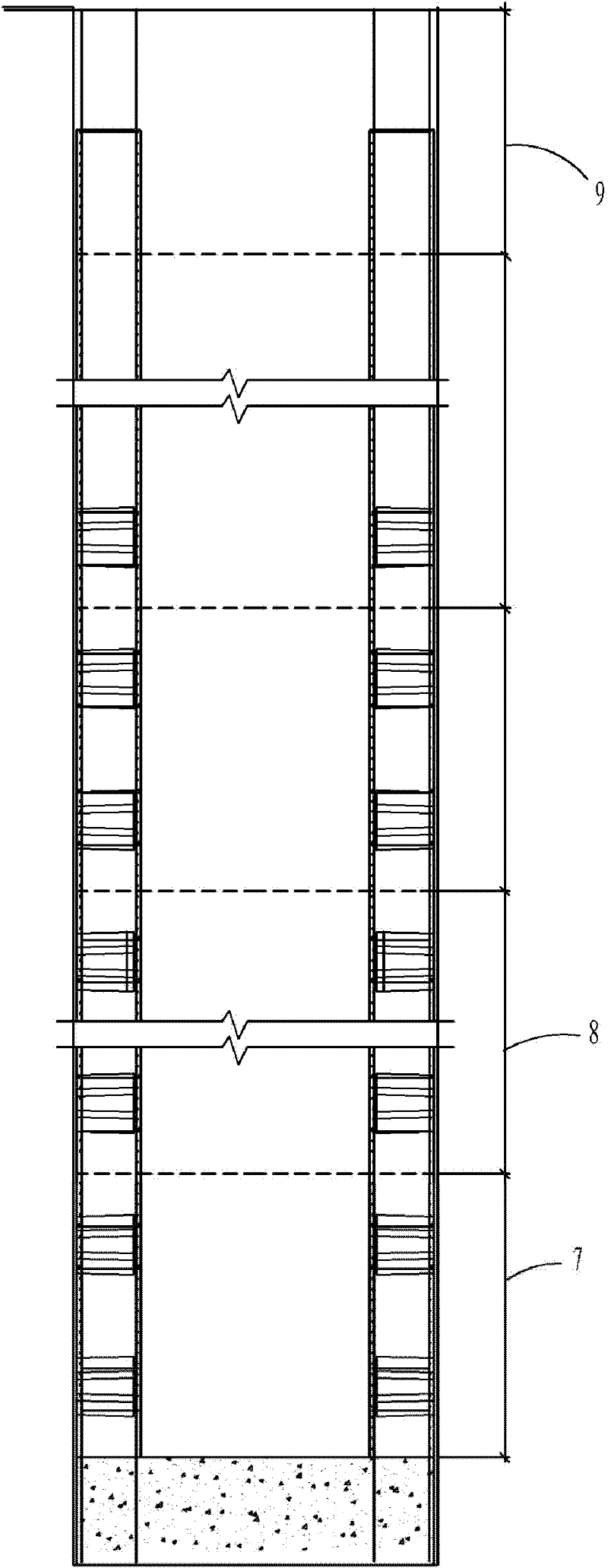

[0031] 3. image 3 As shown, in the pile-forming hole, the first section of FRP composite struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com