Carbon-containing gunning mix for hot-state gunning mix of converter as well as preparation method and using method of carbon-containing gunning mix

A gunning material and converter technology, applied in the field of converter gunning repair, can solve the problems that the effect of repair cannot meet the requirements of steelmaking, affect the purity of molten steel, affect the quality of tapping, etc., so as to eliminate the risk of phosphorus increase, strength and Excellent volume stability, stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

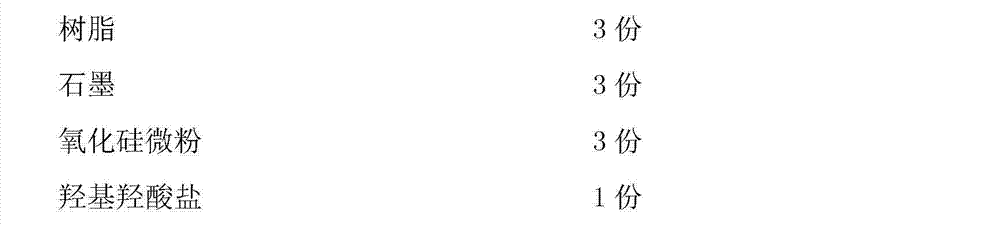

[0025] The carbon-containing gunning material used for hot-state gunning of converters is made of the following raw materials in proportion by weight:

[0026]

[0027]

[0028] The particle size of the above-mentioned magnesia or magnesia-calcium sand is formed by the following proportioning by weight:

[0029] 3≤particle size≤1mm 30 parts

[0030] 1

[0031] 0mm

[0032] The production method of carbon-containing gunning material is as follows:

[0033] 1) Raw material crushing, screening and fine grinding: Grinding and sieving magnesia or magnesia-calcium sand into the required particle size according to the particle size distribution;

[0034] 2) Binder co-grinding: After weighing magnesia or magnesia-calcium sand fine powder and instant powdered sodium silicate, resin, graphite, silicon oxide micropowder, and hydroxy hydroxy acid salt according to weight, add them to the vibrating mill for co-grinding ...

Embodiment 2

[0041] A method for manufacturing an ultra-pure carbon-containing gunning material, which is made from the following raw materials in proportions by weight:

[0042]

[0043] The particle size of the above-mentioned magnesia or magnesia-calcium sand is formed by the following proportioning by weight:

[0044] 3≤particle size≤1mm 35 parts

[0045] 1

[0046] 0mm

[0047] The method of making and using the carbon-containing gunning material are the same as in Example 1.

Embodiment 3

[0049] A method for manufacturing an ultra-pure carbon-containing gunning material, which is made from the following raw materials in proportions by weight:

[0050]

[0051] The particle size of the above-mentioned magnesia or magnesia-calcium sand is formed by the following proportioning by weight:

[0052] 3≤particle size≤1mm 30 parts

[0053] 1

[0054] 0mm

[0055] The method of making and using the carbon-containing gunning material are the same as in Example 1.

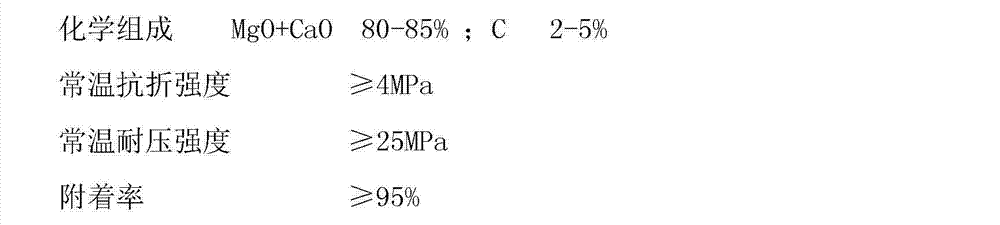

[0056] The technical indicators of the above finished products are:

[0057] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com