Negative electrode material and preparation method thereof, negative electrode and all-solid-state lithium battery

A negative electrode material and negative active material technology, applied in the field of negative electrode and all-solid-state lithium battery, lithium ion battery negative electrode material and its preparation, can solve the problems of fragile silicon film and the decrease of electrochemical performance of silicon negative electrode material, and achieve good electronic performance. Effect of conductance and ionic conductance, good volume stability, good electrochemical performance and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

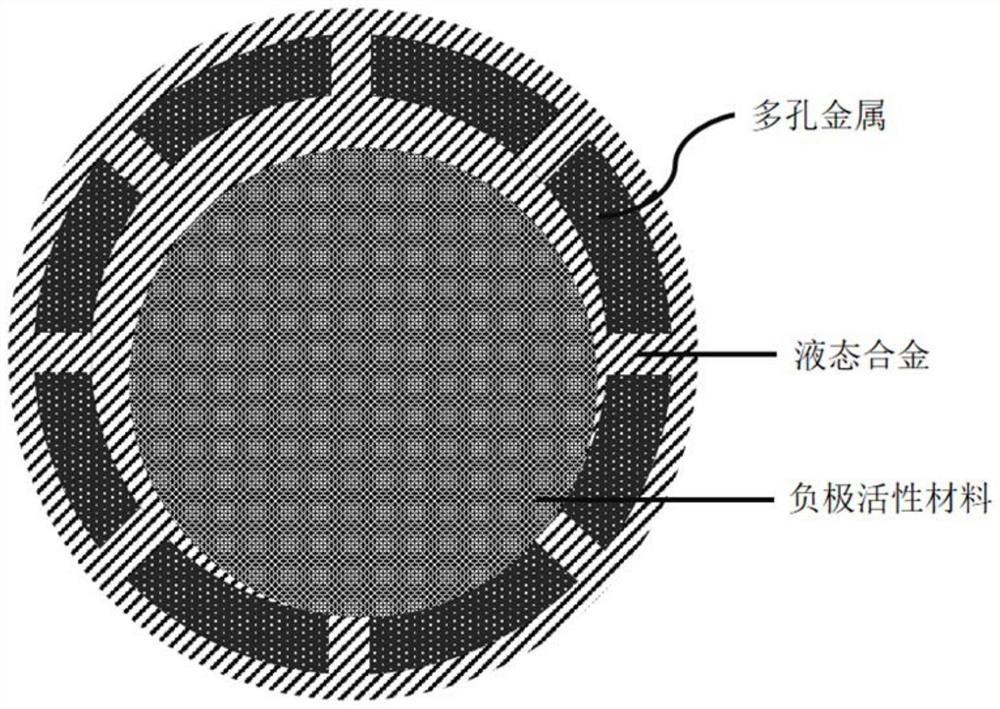

Image

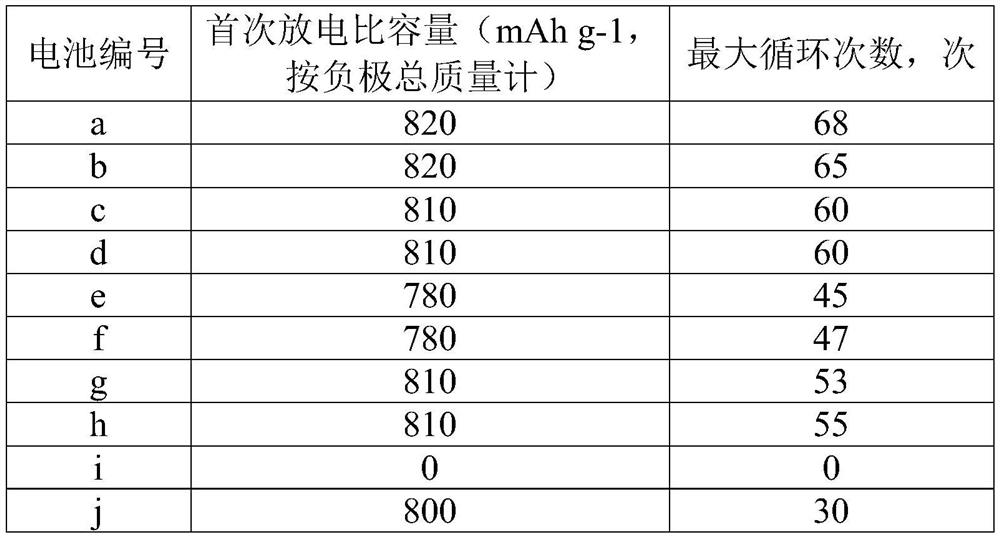

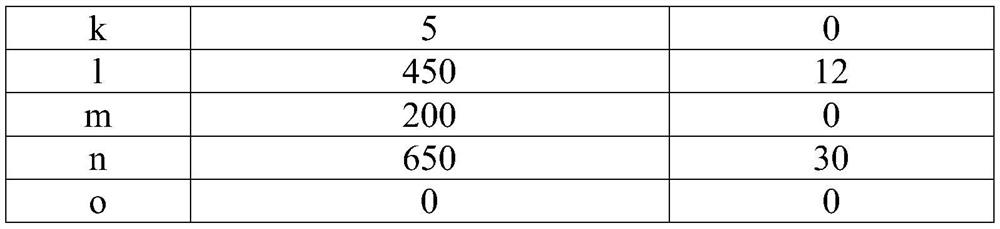

Examples

Embodiment 1

[0055] This example is used to illustrate the preparation process of the negative electrode material of the present disclosure. All manipulations were performed under inert gas (argon) conditions.

[0056] (1) 1424 parts by weight of the lithium-silicon alloy Li 1.71 Si, 20 parts by weight of nano-copper and 20 parts by weight of nano-zinc are mixed and placed in a ball mill for ball milling to obtain the first mixture, wherein the rotating speed of the ball mill is 150rpm, and the ball milling time is 20min, wherein the first mixture includes The first core and the first cladding layer clad on the surface of the first core, the first core is made of lithium silicon alloy Li 1.71 Si, the first cladding layer is composed of a mixture of nano-copper and nano-zinc.

[0057] (2) Heat the first mixture prepared in step (1) to 600° C. and continue heating for 2 hours to obtain a second mixture, wherein the second mixture includes a second inner core and a first inner core coated o...

Embodiment 2

[0062] Adopt the method for embodiment 1 to prepare negative electrode material B, the difference is that, the liquid alloy that adopts in the present embodiment is Ga 0.9 sn 0.05 Zn 0.05 .

Embodiment 3

[0064] Negative electrode material C was prepared by the method of Example 1, except that the amount of nano-zinc in step (1) was 10 parts by weight.

[0065] In the negative electrode material C prepared in this embodiment, the porosity of the porous copper is about 35%, and the pore diameter is about 15 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com