Inorganic cementing material with stable and coordinated development of strength and volume and application of inorganic cementing material

An inorganic cementitious material, mass percentage technology, applied in bridge materials, on-site coagulation pavement, roads, etc., can solve the problems of poor stability of mineral composition, reduced durability, long time-consuming deployment, etc., to achieve high strength and Volume stability, good volume stability, and the effect of reducing energy consumption for calcination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

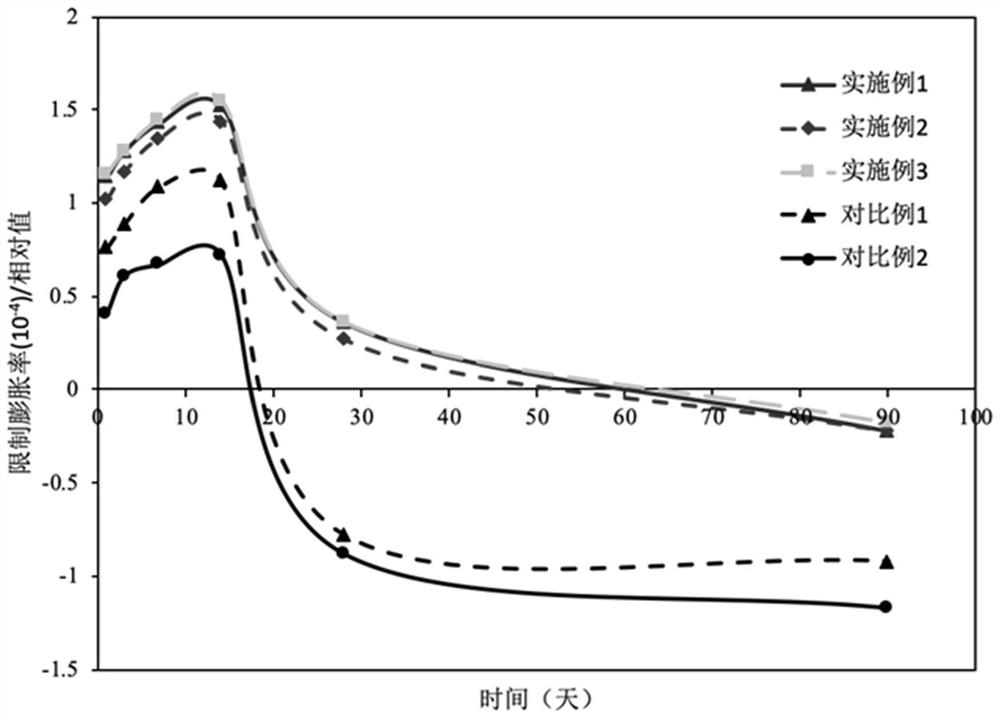

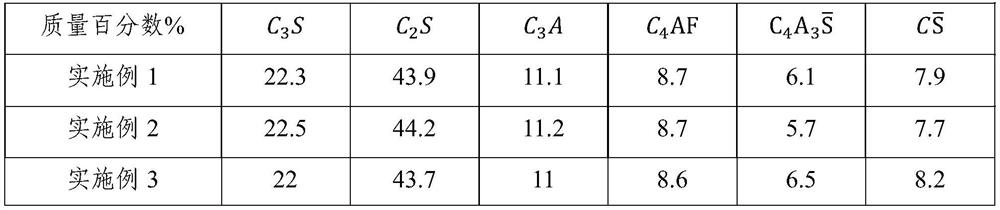

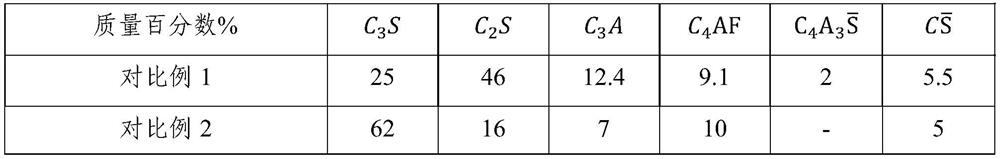

[0038] This embodiment provides 3 groups of inorganic gelling materials with stable and coordinated development of strength and volume. The specific mineral composition is as follows:

[0039] The mineral composition of the inorganic cementitious material of table 1 embodiment

[0040]

[0041] Among them, the C of embodiment 1-3 3 S and C 2 The sum of the quality of S accounts for 66.2%, 66.7%, 65.7% of the total mass of the inorganic gelling material respectively; C 3 A and The sum of the mass accounts for 17.2%, 16.9%, and 17.5% of the total mass of the inorganic gelling material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com