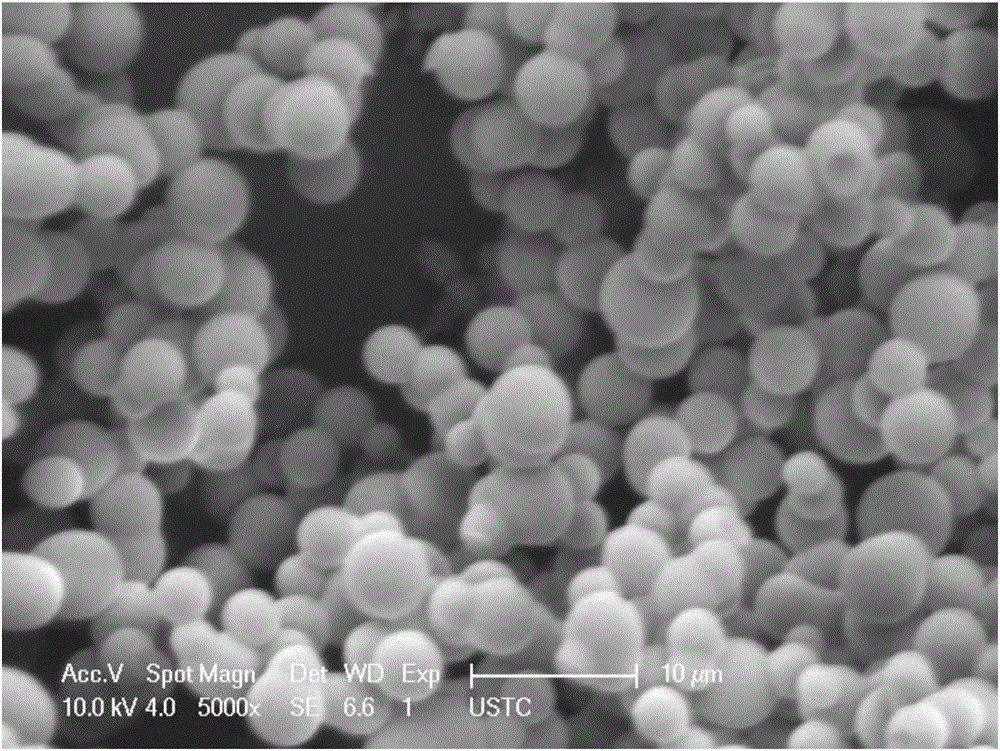

Method for quickly preparing hydrophobic silicon dioxide aerogel at low cost

A technology of hydrophobic silica and aerogel, applied in the direction of silica, silica, chemical instruments and methods, etc., can solve the problems of increasing preparation cost and time, achieve shortening preparation time, good thermal insulation, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

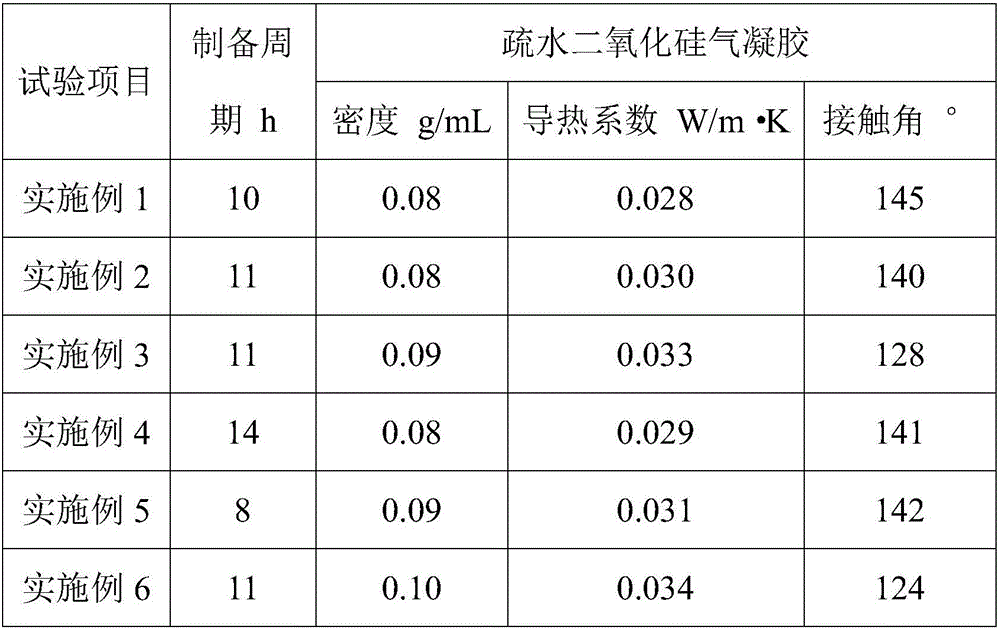

Examples

Embodiment 1

[0040] A method for quickly preparing hydrophobic silica airgel at low cost, comprising the steps of:

[0041] S1. Mix the silicon source, water and surfactant to obtain a precursor solution; add an acid catalyst to the precursor solution, adjust the pH=3.5, and then hydrolyze to obtain a sol;

[0042]S2. Add an alkali catalyst dropwise to the sol obtained in S1, stir continuously during the dropwise addition, adjust the pH to 6.5, let the gel stand, age, and dry under normal pressure to obtain a hydrophobic silica airgel.

Embodiment 2

[0044] A method for quickly preparing hydrophobic silica airgel at low cost, comprising the steps of:

[0045] S1, methyltrimethoxysilane, water and DuPont Mix well to obtain a precursor solution; add an aqueous hydrochloric acid solution with a concentration of 0.1mol / L to the precursor solution, adjust the pH=3, then adjust the temperature to 45°C, and hydrolyze for 0.5h to obtain a sol, wherein methyltrimethoxysilane and The volume ratio of water is 1:4, DuPont and precursor solution volume ratio is 0.5:100;

[0046] S2. Add dropwise an ammonia solution with a concentration of 0.5 mol / L to the sol obtained in S1. Stir continuously during the dropwise addition, adjust the pH to 6.5, let the gel stand for 10 minutes, heat up to 45°C, age for 2 hours, and heat up to 60°C , dried for 2 hours, then heated to 120°C, dried for 2 hours, then heated to 150°C, dried for 4 hours to obtain a hydrophobic silica airgel.

[0047] The hydrophobic silica airgel that embodiment 2 is mad...

Embodiment 3

[0051] A method for quickly preparing hydrophobic silica airgel at low cost, comprising the steps of:

[0052] S1, the silicon source, water and DuPont Mix well to obtain a precursor solution; add an aqueous hydrochloric acid solution with a concentration of 0.1mol / L to the precursor solution, adjust the pH=3, then adjust the temperature to 45°C, and hydrolyze for 0.5h to obtain a sol, wherein the volume ratio of the silicon source to water is 1:3, the silicon source is a mixture of methyltrimethoxysilane and ethyl orthosilicate, in which the molar content of methyltrimethoxysilane is 60%, DuPont and precursor solution volume ratio is 0.5:100;

[0053] S2. Add dropwise an ammonia solution with a concentration of 0.5 mol / L to the sol obtained in S1. During the dropwise addition, keep stirring to adjust the pH to 6.5, let the gel stand for 5 minutes, heat up to 45°C, age for 2 hours, and heat up to 60°C. , dried for 2 hours, then heated to 120°C, dried for 2 hours, then heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com