Heat-insulation slurry composition and applications thereof

A technology of thermal insulation and composition, which is applied in the direction of thermal insulation and building components, can solve the problems of limited application range, poor thermal insulation performance, complicated construction steps, etc., and achieve excellent thermal insulation performance, high mechanical strength, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

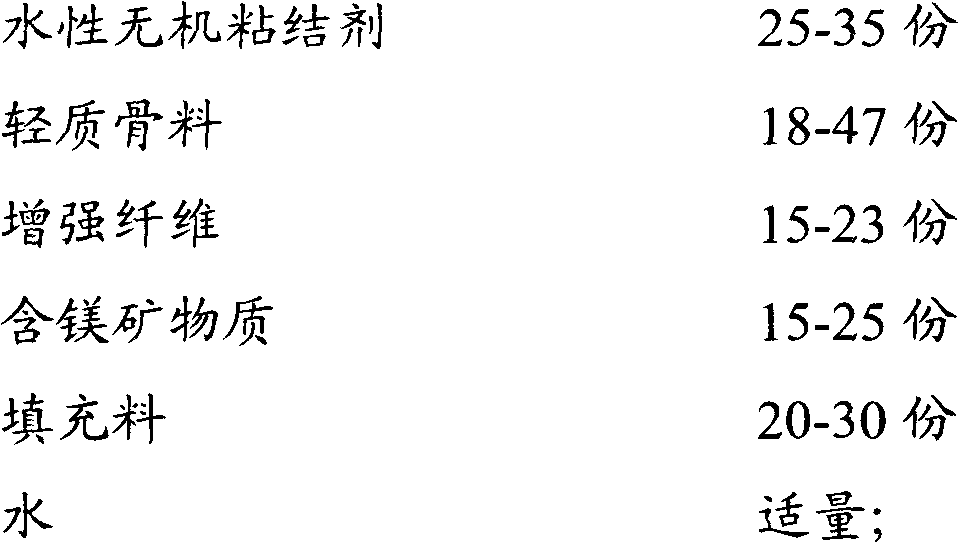

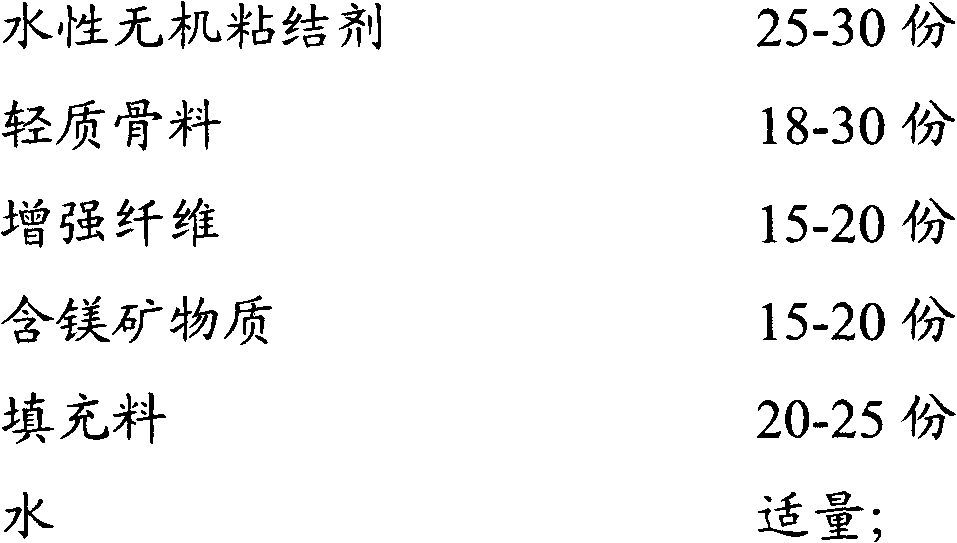

[0055] The components and proportions of the slurry compositions in Examples 1-6 of the present invention are shown in Table 2 below.

[0056] According to the composition ratio of Examples 1-6, the thermal insulation board is prepared according to the following steps:

[0057] First weigh the reinforcing fiber and soak it in water at 60°C to 80°C with a small amount of sodium dodecylbenzenesulfonate, stir continuously until it becomes a slurry; take lightweight aggregate and soak it in water at room temperature for 1-2 hours;

[0058] According to the corresponding examples in Table 2, weigh the aforementioned pretreated aqueous inorganic binder solution (numbered as WNOA-1 ~ WNOA-9), the reinforcing fiber solution, and add them to the mixer together with the magnesium-containing minerals in, and add an appropriate amount of water to mix and stir to obtain a slurry.

[0059]Add fillers weighed according to the corresponding examples in Table 2 and pretreated lightweight aggr...

Embodiment 7-54

[0071] The present invention can also add one or more of inorganic powdery binders, foaming agents, active agents, and stabilizers to the slurry composition on the basis of Examples 1-6, and its specific slurry combination See Example 7-54 in Table 3 for details.

[0072] According to embodiment 7-54, heat insulation board is prepared according to the following steps:

[0073] First weigh the reinforcing fiber and soak it in water at 60°C-80°C plus a small amount of sodium dodecylbenzenesulfonate, stir continuously until it becomes a slurry; take lightweight aggregate and soak it in water at room temperature for 1-2 hours; The components in the mineral and inorganic powder binder are stirred and mixed evenly; the foaming agent, active agent, and stabilizer are dissolved in water respectively, and set aside;

[0074] Take the aforementioned pretreated aqueous inorganic binder solution (numbering is WNOA-1~WNOA-9), the reinforcing fiber solution respectively by the correspondin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com