Light weight wall brick and method of manufacturing the same

A manufacturing method and technology for wall tiles, applied in the field of wall tiles, can solve the problems of poor combustion resistance, poor heat resistance, and low strength of plastic brick bodies, and achieve the effects of good thermal insulation effect, simple and convenient manufacturing process, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

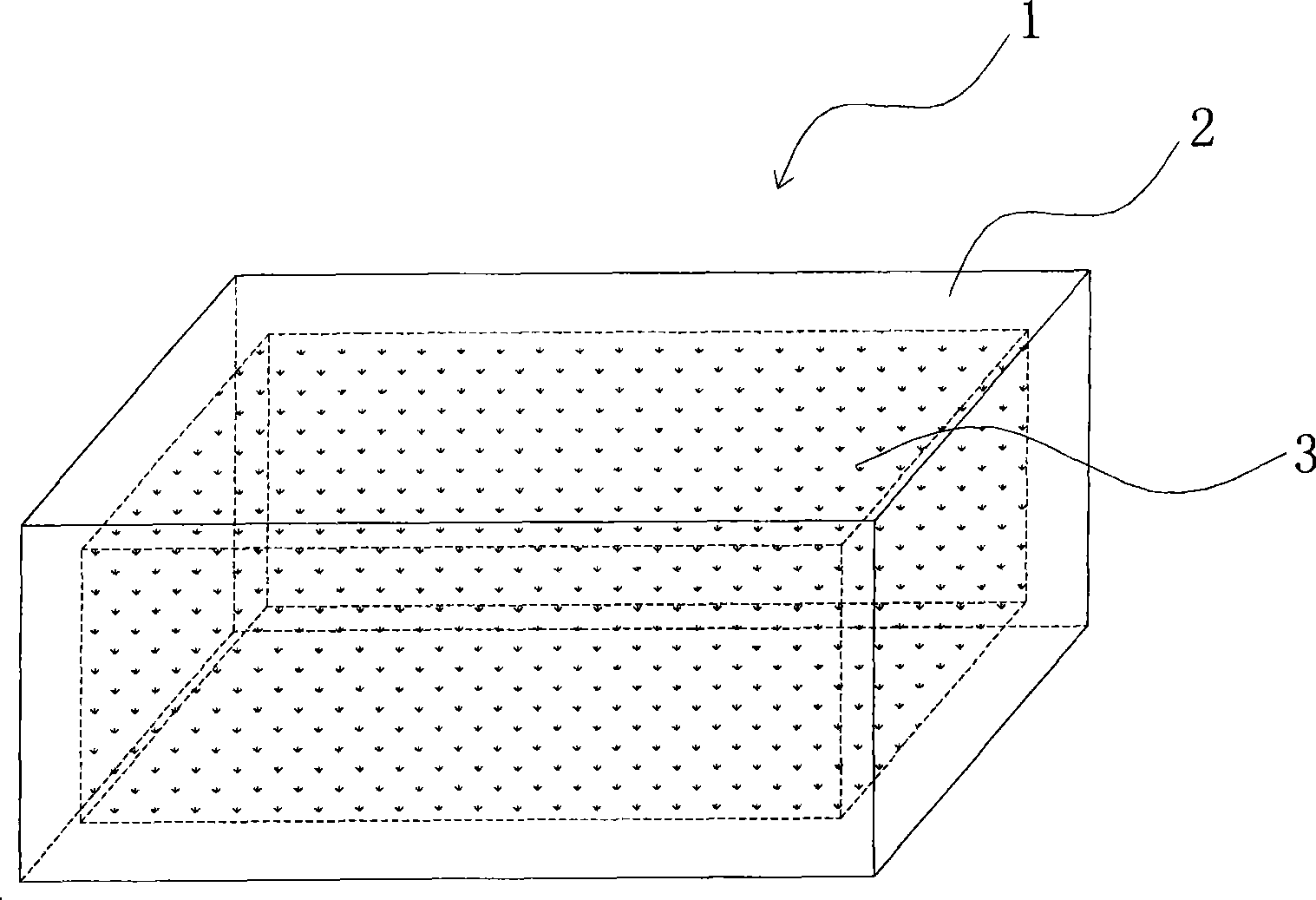

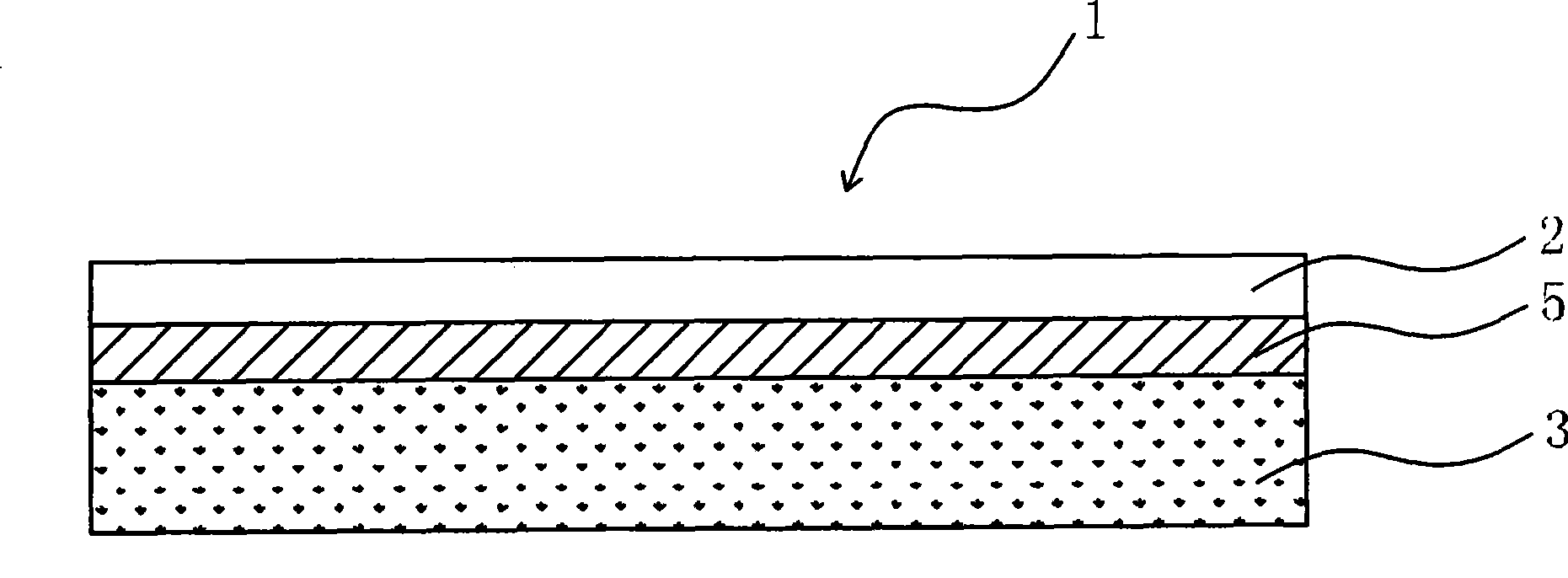

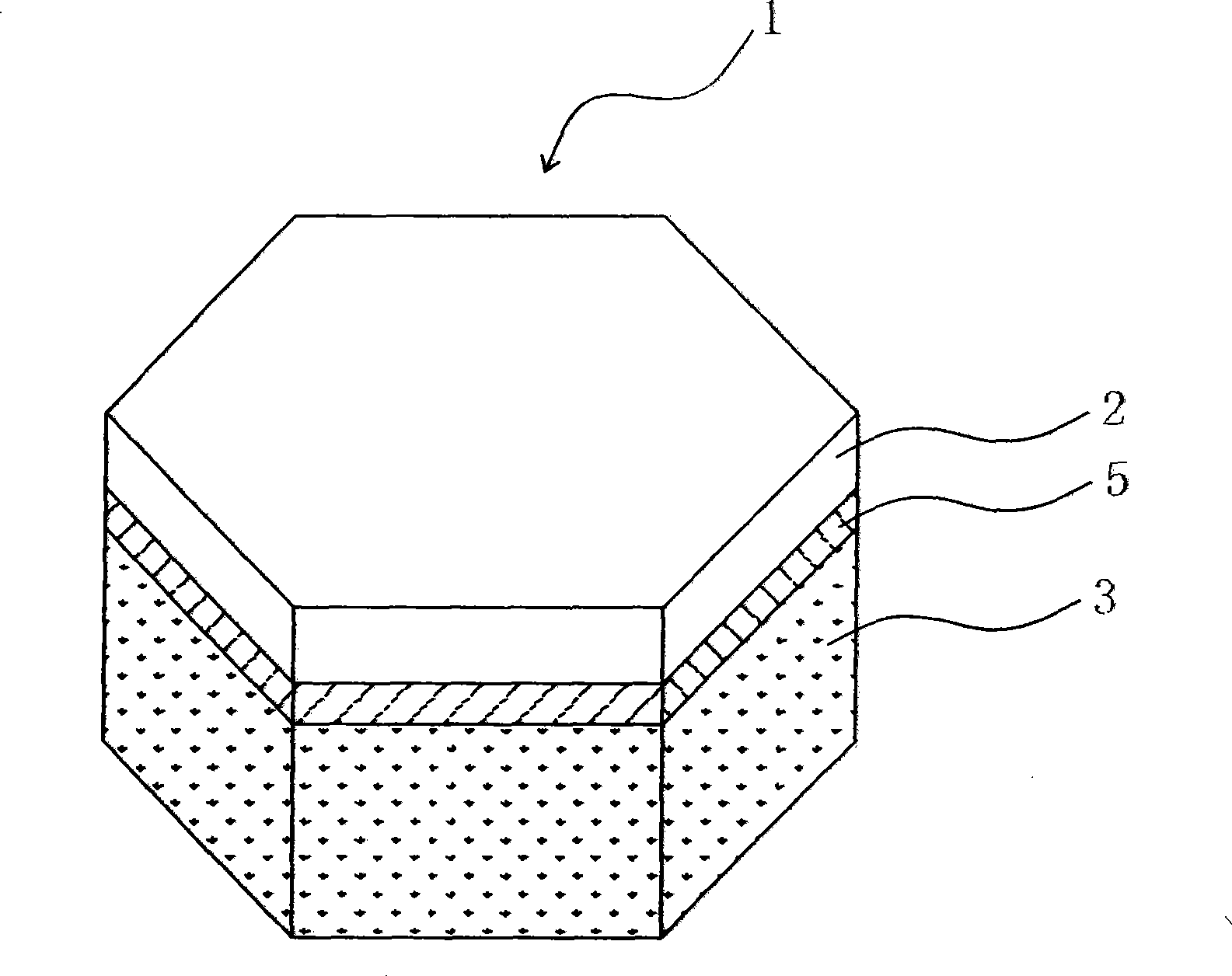

[0035] The structure of the lightweight wall brick of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0036] The present invention proposes a lightweight wall brick, comprising a decorative layer and a lightweight material body, the decorative layer covering at least one side of the lightweight material body; and the decorative layer is made of aggregate and a binder covering the aggregate composition, preferably, the aggregate is pre-coated by the binder to form coated aggregate particles, and then bonded by the binder, and the decorative layer also contains a flame retardant, And when in use, the flame retardant is added into the binder; the light material body is made of light material and pressed from light material. The lightweight material body is wood chips, wood silk, ceramic foam, plastic foam, expanded perlite body or foamed cement body, through the structural design of the light material body, the weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com