Composite sound absorbing device with built-in resonant cavity

A sound-absorbing device and resonant cavity technology, which is applied in the direction of sound-emitting devices, instruments, building components, etc., can solve the problems of insufficient low-frequency sound absorption, etc., and achieve the effects of widening the sound-absorbing frequency band, improving the sound-absorbing coefficient, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

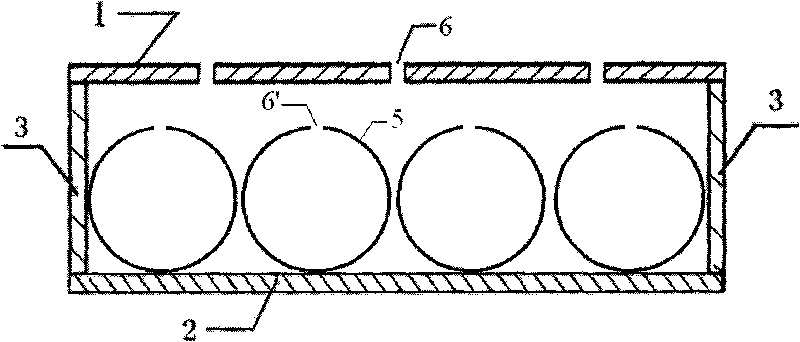

[0042] refer to figure 1 In this embodiment, a composite sound-absorbing device with a built-in resonant cavity of the present invention is produced. The device is a closed cavity composed of a perforated plate 1 made of stainless steel, a back plate 2 made of stainless steel and a side plate 3 made of stainless steel. A square stainless steel plate with a thickness of 5 mm. The first hole 6 is provided on the perforated plate 1. The diameter of the first hole 6 is 3 mm. The perforation rate of the first hole 6 is 28%. The arrangement of the first holes 6 on the perforated plate 1 is regular. There are four resonant cavities 5 in the closed cavity, the resonant cavity 5 is an aluminum spherical cavity, and the volume of the resonant cavity 5 is 1.4×10 4 mm 3 , the cavity wall thickness of the resonant cavity 5 is 5 mm; there is a second hole 6' on the cavity wall of the resonant cavity 5, the aperture d' of the second hole 6' is 2 mm, and the perforation rate σ' of the secon...

Embodiment 2

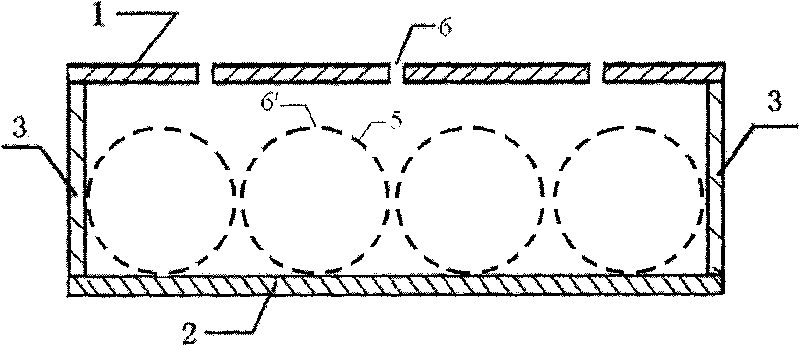

[0044] refer to figure 2 In this embodiment, a composite sound-absorbing device with a built-in resonant cavity of the present invention is produced. The device is a closed cavity composed of a perforated plate 1 made of stainless steel, a back plate 2 made of stainless steel and a side plate 3 made of stainless steel. The depth D of the closed cavity is 50 mm, and the perforated plate 1 is a circle with a diameter of 100 mm. Shaped stainless steel plate with a thickness of 0.7 mm. The perforated plate 1 is provided with a first hole 6. The diameter of the first hole 6 is 1.7 mm. The perforation rate of the first hole 6 is 4.6%. The arrangement of the first holes 6 on the perforated plate 1 Arranged in a regular square; there are four resonant cavities 5 in the closed cavity, the resonant cavity 5 is a plastic sphere cavity, and the volume of the resonant cavity 5 is 3.35×10 4 mm 3 , the thickness of the cavity wall of the resonant cavity 5 is 0.4mm; there are 26 second hol...

Embodiment 3

[0050] refer to figure 2 In this embodiment, a composite sound-absorbing device with a built-in resonant cavity of the present invention is fabricated. The device is a closed cavity composed of a perforated plate 1 made of stainless steel, a back plate 2 made of stainless steel and a side plate 3 made of stainless steel. The depth D of the closed cavity is 100 mm, and the perforated plate 1 is a circle with a diameter of 100 mm. Shaped stainless steel plate with a thickness of 0.7 mm. The perforated plate 1 is provided with a first hole 6. The diameter of the first hole 6 is 1.7 mm. The perforation rate of the first hole 6 is 4.6%. The arrangement of the first holes 6 on the perforated plate 1 It is arranged in a regular square; 9, 7, 4 and 1 resonant cavities 5 are placed in the closed cavity in stages, the resonant cavity 5 is a plastic sphere cavity, and the volume of the resonant cavity 5 is 3.35×10 4 mm 3 , the thickness of the cavity wall of the resonant cavity 5 is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com