Multi-layer composite plate

A composite board and outer layer technology, which is applied in the direction of layered products, synthetic resin layered products, glass/slag layered products, etc. problem, to achieve the effect of reducing the sound intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

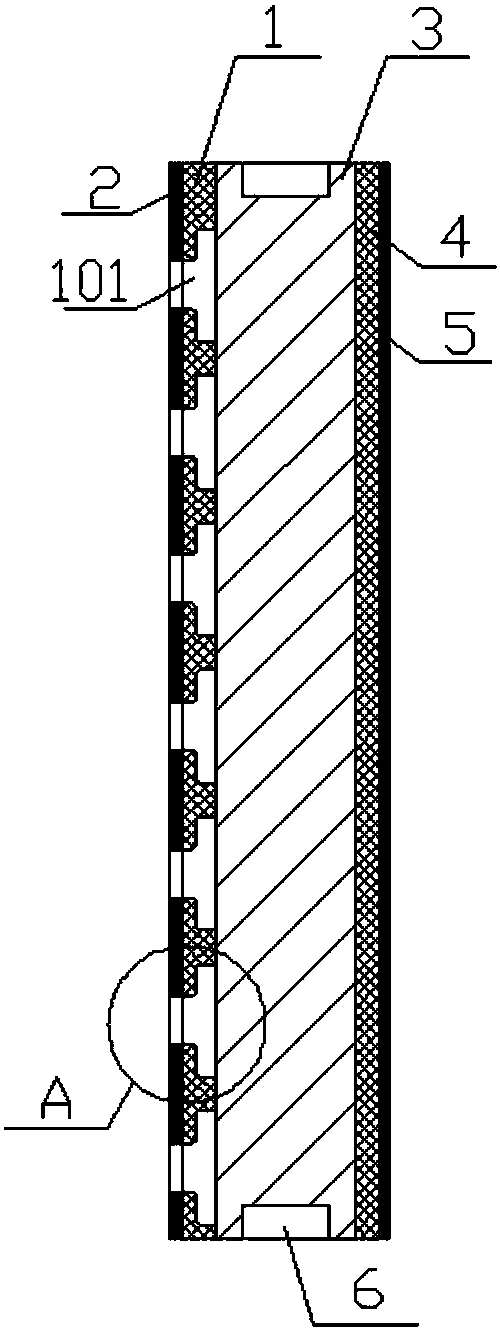

[0028] Such as figure 1 As shown, a multi-layer composite board includes a glass fiber outer board 1, a sound-absorbing board 3 and a glass fiber inner board 4, the outer surface of the glass fiber outer board 1 is provided with a flame-retardant outer layer 2, and the glass fiber outer board The inner side of the board 1 is connected to the outer side of the sound-absorbing board 3, and the inner side of the sound-absorbing board 3 is connected to the outer side of the glass fiber inner board 4, and the inner layer surface of the glass fiber inner board 4 is provided with a flame-retardant inner layer 5, The flame-retardant outer layer 2, the glass fiber outer panel 1, the sound-absorbing panel 3, the glass fiber inner panel 4 and the flame-retardant inner layer 5 are sequentially connected from outside to inside to form a multilayer composite board.

[0029] Specifically, the sound-absorbing panel 3 is a pressed loofah board, which is uniformly mixed with loofah fiber and or...

Embodiment 2

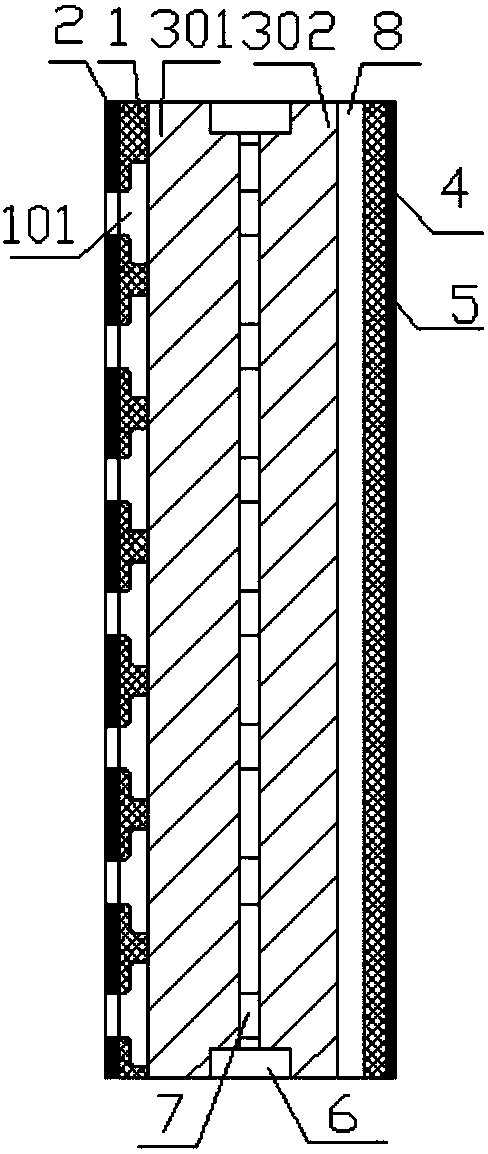

[0031] Such as figure 2 , 3 As shown, a multi-layer composite board includes a glass fiber outer board 1, a sound-absorbing board 3 and a glass fiber inner board 4, and also includes a porous sound-insulating board 7, and the sound-absorbing board 3 includes a first sound-absorbing board 301 and a second sound-absorbing board 302; the outer surface of the glass fiber outer plate 1 is provided with a flame-retardant outer layer 2, the inner side of the glass fiber outer plate 1 is connected to the outer side of the first sound-absorbing panel 301, and the inner side of the first sound-absorbing panel 301 passes through The porous sound-insulating board 7 is connected to the outside of the second sound-absorbing board 302, and a sound-absorbing cavity 8 is provided between the inside of the second sound-absorbing board 302 and the outside of the glass fiber inner board 4, and the inside of the glass fiber The inner surface of the board 4 is provided with a flame-retardant inne...

Embodiment 3

[0043] Such as figure 2As shown, a multi-layer composite board includes a glass fiber outer board 1, a sound-absorbing board 3 and a glass fiber inner board 4, and also includes a porous sound-insulating board 7, and the sound-absorbing board 3 includes a first sound-absorbing board 301 and a second sound-absorbing board 302; the outer surface of the glass fiber outer plate 1 is provided with a flame-retardant outer layer 2, the inner side of the glass fiber outer plate 1 is connected to the outer side of the first sound-absorbing panel 301, and the inner side of the first sound-absorbing panel 301 passes through The porous sound-insulating board 7 is connected to the outside of the second sound-absorbing board 302, and a sound-absorbing cavity 8 is provided between the inside of the second sound-absorbing board 302 and the outside of the glass fiber inner board 4, and the inside of the glass fiber The inner surface of the board 4 is provided with a flame-retardant inner laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com