Hybrid solid-liquid electrolyte lithium storage battery

A lithium battery and solid-state electrolyte technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, lithium battery, etc., can solve problems such as lithium battery safety hazards, lithium battery short circuit, etc., achieve excellent mechanical strength, ensure normal use, and improve safety Effects on Performance and Battery Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

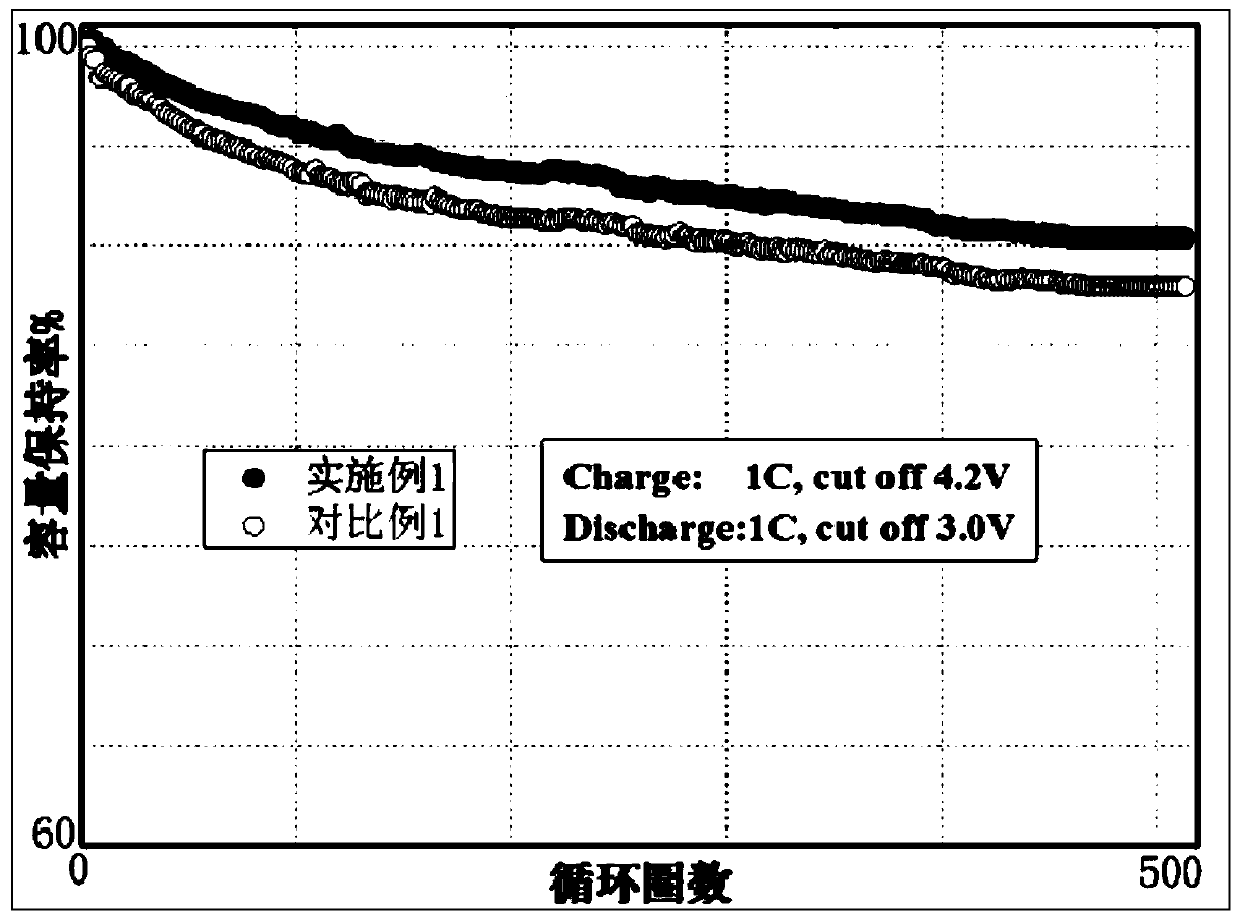

Embodiment 1

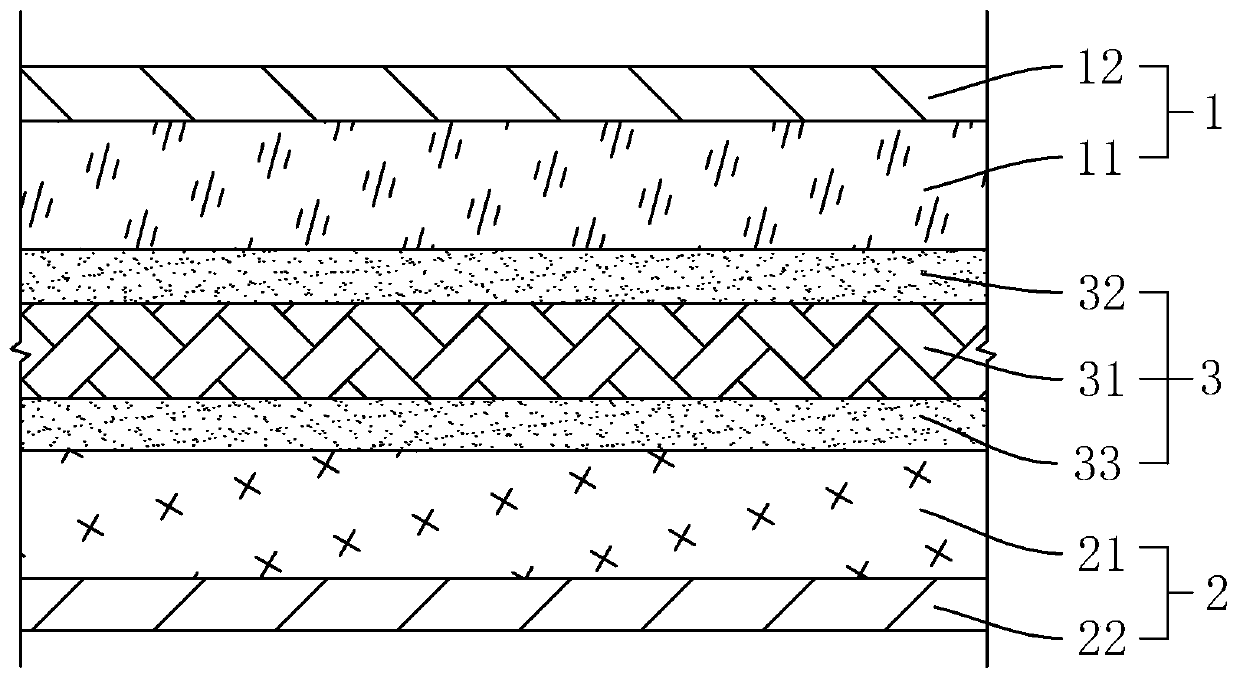

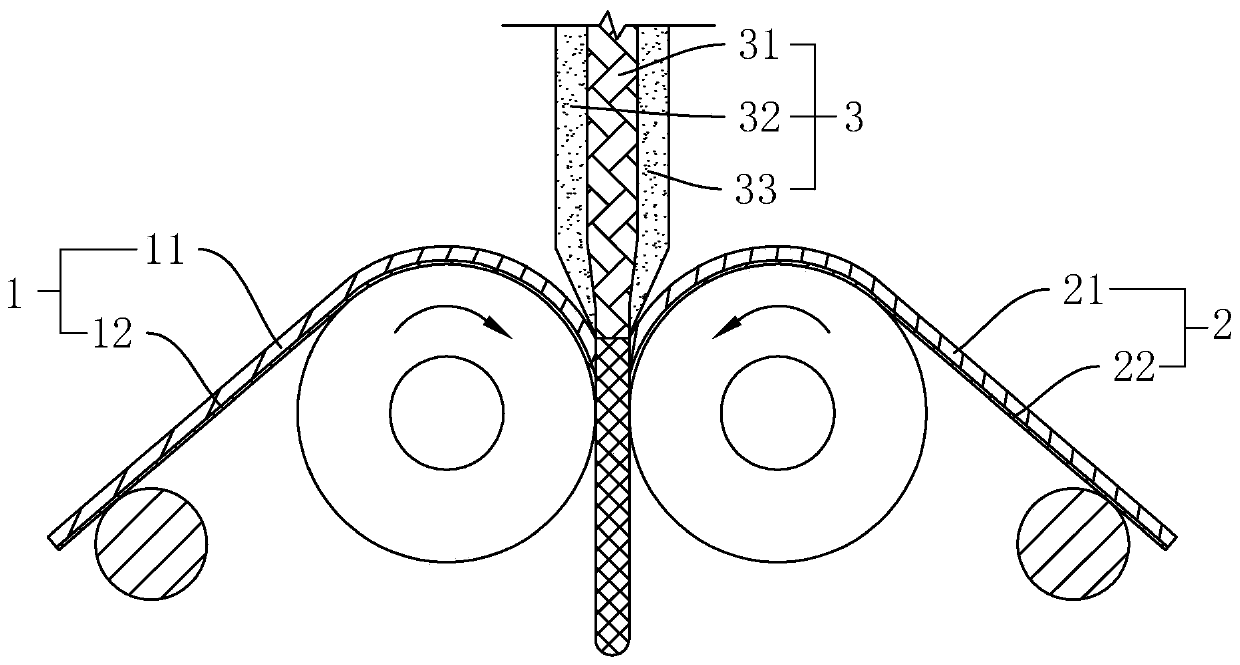

[0061] see figure 2 , a method for preparing a mixed solid-liquid electrolyte lithium storage battery, comprising the following steps:

[0062] ① Preparation of buffer gel

[0063] Prepare the buffer rubber for forming the first buffer rubber layer 32 and the second buffer rubber layer 33, and the composition of the first buffer rubber layer 32 and the second buffer rubber layer 33 is the same, specifically: weighed according to the weight ratio of 5:1 Take 5g of the buffer rubber layer lithium salt LiTFSI and 1g of the buffer rubber layer additive PEO, dissolve the two in 114g of acetonitrile to form an organic polymer electrolyte gel with a solid content of 5%, then add the buffer rubber layer inorganic solid electrolyte LLTO, mix and disperse Form corresponding buffer glue, wherein the weight of the inorganic solid electrolyte of the buffer glue layer respectively accounts for 40% of the weight of the corresponding electrolyte buffer glue.

[0064] ② Preparation of solid...

Embodiment 2

[0077] The difference from Example 1 is that in the preparation of the buffer glue in this embodiment, the buffer glue layer additive is PEO, only the buffer glue layer lithium salt is added in the second buffer glue layer 33, and the buffer glue layer lithium salt For LiTFSI, weigh 5g of the buffer rubber layer lithium salt LiTFSI and 10g of the buffer rubber layer additive PEO in acetonitrile according to a weight ratio of 5:10 to form an organic polymer electrolyte gel with a solid content of 10%; the buffer rubber layer inorganic solid electrolyte For LAGP, in the formed electrolyte buffer gel, the weight of the inorganic solid electrolyte of the buffer gel layer accounts for 60% of the weight of the corresponding electrolyte buffer gel.

[0078] In the preparation of the solid electrolyte masterbatch, the core layer inorganic solid electrolyte is LAGP, the electrolyte polymer is PAA, and the electrolyte additive is stearic acid, and the weight of the core layer inorganic s...

Embodiment 3

[0084] The difference from Example 1 is that in the preparation of the buffer glue in this embodiment, the buffer glue layer additive is PEC, and the buffer glue layer lithium salt is LiBOB, which weighs 10g of the buffer glue layer lithium in a weight ratio of 1:1. The salt LiBOB and the buffer layer additive PEC are dissolved in water to form an organic polymer electrolyte gel with a solid content of 10%. The buffer layer inorganic solid electrolyte is LATP. In the formed electrolyte buffer gel, the weight of the buffer layer inorganic solid electrolyte is respectively Accounting for 20% of the weight of the corresponding electrolyte buffer gel.

[0085] In the preparation of solid electrolyte masterbatch, the core layer inorganic solid electrolyte is a mixture of LATP and LLTO with a weight ratio of 1:1, the electrolyte polymer is PMMA, the electrolyte additive is paraffin, and the core layer inorganic solid electrolyte LATP, electrolyte polymer PMMA The weight ratio of par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com