Back panel of solar cell and preparation method thereof

A technology for solar cells and back sheets, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problems of easily fluctuating adhesive layer thickness, difficult PVF bonding, long operating cycle, etc., and is suitable for large-scale promotion. Application, simplified molding process, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

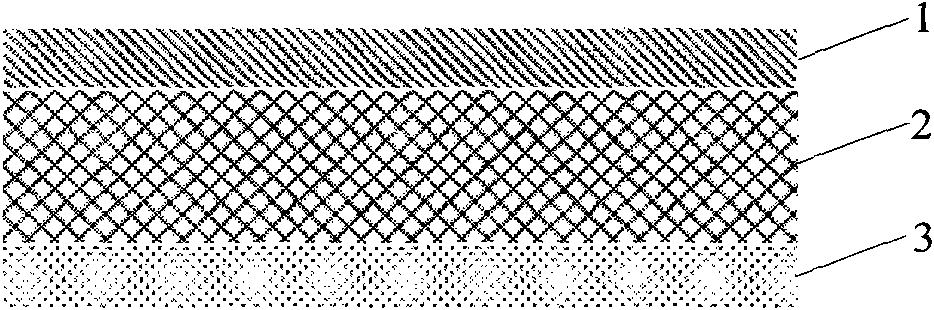

[0040] The structure of the solar cell backplane is as figure 1 shown. Wherein, 1 layer is bonding weather-resistant layer, and thickness is 25 microns, and the weight ratio of main raw material PVDF resin and EVA resin is 75: 25, accounts for 85% of bonding weather-resistant layer gross weight, adds mixing aid I: 13% by weight Titanium dioxide, 0.5% by weight of UV absorber UVP-327, 1% by weight of 2,2'-methylene-bis-(4-methyl-6-tert-butylphenol) and 0.5% by weight of peroxide Hydrogen dicumyl, said weight ratio is based on the weight of the bonding weather-resistant layer 1. The 2nd layer is the adhesion enhancement layer, the thickness is 250 microns, the weight ratio of main raw materials PET resin and PMMA resin is 70: 30, accounts for 90% of the total weight of the adhesion enhancement layer, adds mixing auxiliary agent II: titanium dioxide of 8.5% by weight , 0.5% by weight of UV absorber UVP-327 and 1% by weight of 2,2'-methylene-bis-(4-methyl-6-tert-butylphenol), th...

Embodiment 2

[0046] The structure of the solar cell backplane is as figure 1 shown. Wherein, 1 layer is bonding weather-resistant layer, and thickness is 35 microns, and the weight ratio of main raw material PVDF resin and EVA resin is 70: 30, accounts for 80% of the total weight of blended gold layer, adds the titanium dioxide of 17% weight, 1 % weight of light stabilizer GW-540, 1.2% weight of two (3,5-tertiary butyl-4-hydroxyl phenyl) sulfide and 0.8% weight of dicumyl oxide (DCP), the weight It is based on the weight of the adhesive weather-resistant layer 1. The 2 layers are the bonding enhancement layer, the thickness is 180 microns, the weight ratio of the main raw materials PET resin and PMMA resin is 80:20, accounting for 90% of the total weight of the blended gold layer, adding 8% by weight of titanium dioxide, 1% by weight of Light stabilizer GW-540 and 1% by weight of bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, the weight being based on the weight of the adhesion-enhanci...

Embodiment 3

[0049] The structure of the solar cell backplane is as figure 1 shown. Among them, one layer is a bonding weather-resistant layer with a thickness of 15 microns. The weight ratio of the main raw material PVDF resin to EVA resin is 90:10, accounting for 91% of the total weight of the blended gold layer, adding 6% by weight of titanium dioxide, 1.5 % by weight of UV absorber UV-9, 1.2% by weight of 2,6-tertiary butyl-4-methylphenol and 0.3% by weight of benzoyl peroxide (BPO), said weight is based on bond weathering Weight meter for layer 1. The 2 layers are the bonding enhancement layer, the thickness is 300 microns, the weight ratio of the main raw materials PET resin and PMMA resin is 60:40, accounting for 80% of the total weight of the blended gold layer, adding 17% by weight of titanium dioxide, 1.5% by weight of UV absorber UV-9 and 1.5% by weight of 2,6-tertiary butyl-4-methylphenol based on the weight of the adhesion enhancing layer 2. The third layer is a bonding moi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com