Method for manufacturing expanded polytetrafluoroethylene plate

A polytetrafluoroethylene plate and polytetrafluoroethylene technology, which is applied in the field of sealing materials, can solve problems such as no corresponding literature reports, and achieve the effects of being beneficial to civilian promotion, low cost, and low stress relaxation rate enhancement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

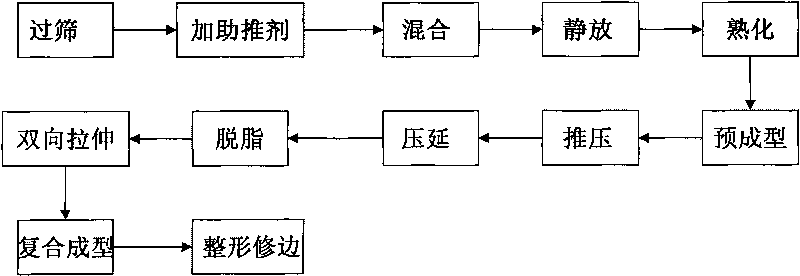

[0046] The manufacture method of expanded polytetrafluoroethylene (ePTFE) plate, its manufacture step is as follows:

[0047] (1) Put the polytetrafluoroethylene dispersed resin in a freezer to refrigerate at a temperature of 15° C. for 24 hours, and then sieve through an 8-mesh sieving machine.

[0048] (2) Mix the sieved polytetrafluoroethylene dispersion resin with the propellant, and let it stand for 2 hours; then stir for 14 minutes, and the mixing temperature is not higher than 19°C; let it stand for 24 hours; the polytetrafluoroethylene dispersion The parts by weight of the resin and the propellant are as follows: the polytetrafluoroethylene dispersion resin is 75-80, and the propellant is 18-22; the propellant can be one of kerosene solvent oil, sherwood oil or paraffin oil or Mix more than one.

[0049] (3) Carry out aging treatment; the aging treatment is carried out in the aging box, the aging temperature is 50-60° C., and the aging time is about 20-36 hours. Pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com