A method for preparing a material for orthodontic treatment, the material obtained therefrom and its use

An orthodontic and dental technology, applied in the field of orthodontic materials, can solve the problems of insufficient orthodontic stress, lack of high mechanical strength of polymer materials, and poor orthodontic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0140] 1) SiO 2 A was dried in a vacuum oven at 100°C for 2 hours, and the dried SiO 2 A Add to the absolute ethanol in the three-necked flask and stir for 15 minutes to disperse, then add to the ethanol solution containing 4% silane coupling agent KH-550 (produced by Henan Zhongbo Chemical Co., Ltd.), put the mixture in an ultrasonic cleaner After 60 minutes, it was transferred to another three-necked flask, heated and stirred at 78°C and refluxed for 2h, filtered with suction, washed with ethanol, dried in a vacuum oven at 80°C for 2h, ground and sieved. Take the surface-modified nano-silica with an average particle size of 5nm-60nm and dry it in a vacuum oven at 105°C for 2 hours to obtain surface-treated and dried SiO 2 a.

[0141] 2) The dried TPU A, surface treated and dried SiO 2 A. Antioxidant 1010 (Zibo Xiangdong Chemical Co., Ltd.) and Antioxidant 626 (Beijing Wanfuda Fine Chemical Factory) were stirred in a high-speed mixer at a ratio of 98 / 20 / 3 / 0.6 for 20 mi...

Embodiment 3

[0150] Repeat embodiment 1, the difference is: the SiO used in step 1) 2 Replace A with SiO 2 B; in step 2), the feeding ratio is changed to 98 / 5 / 3 / 0.6; in step 3), PETG A is replaced with PETG B; and in step 4), the feeding ratio is changed to 90 / 10.66;

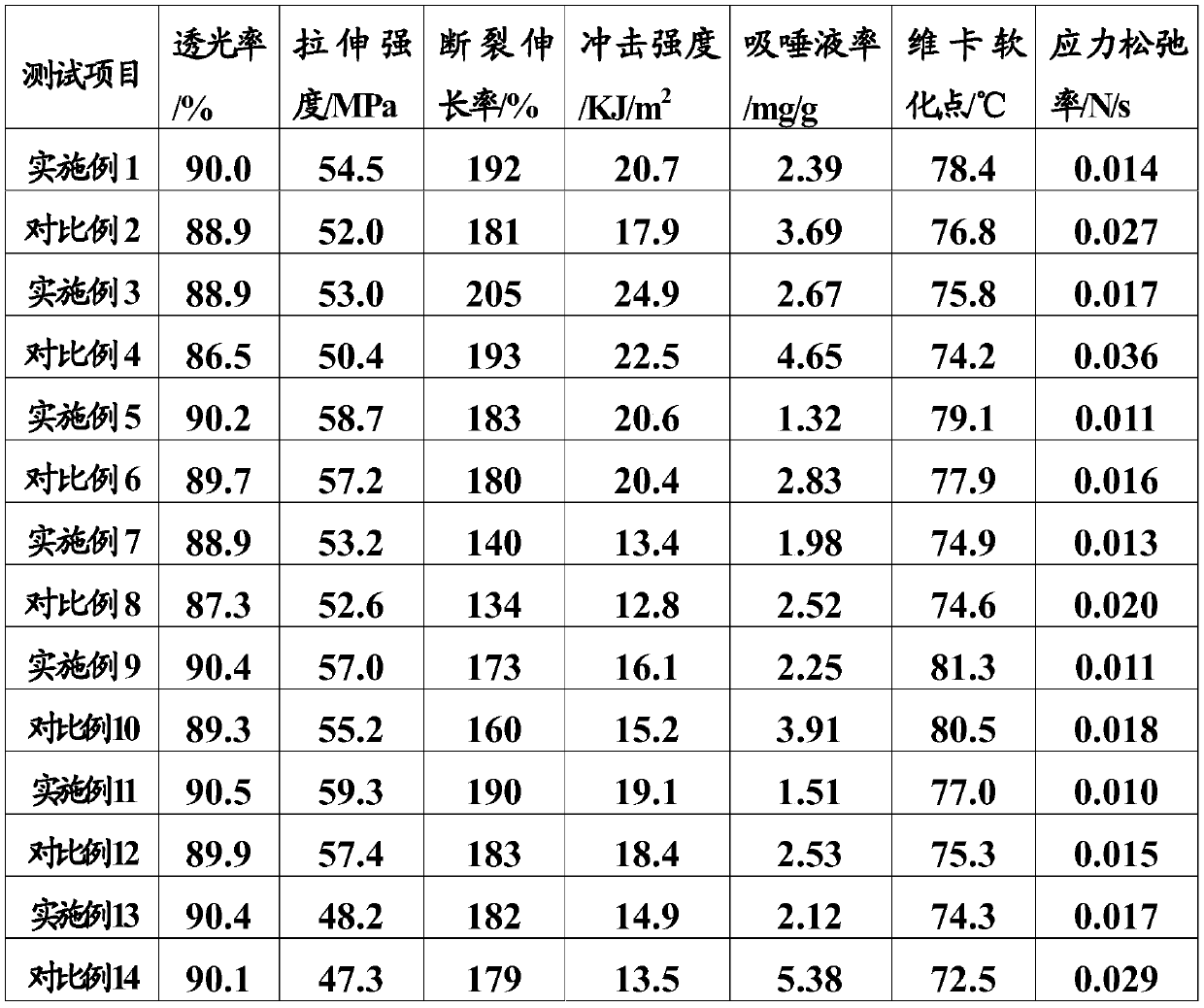

[0151] Various performance tests were performed on the obtained dried hot-pressed film, and the results are shown in Table 1.

Embodiment 5

[0156] Repeat embodiment 1, difference is: step 2) in feed ratio change 196 / 20 / 3 / 0.6; Step 3) in PETG A change PETG B, feed ratio change 68.6 / 9.8; And step 4) The medium feeding ratio is changed to 78.4 / 21.96.

[0157] Various performance tests were performed on the obtained dried hot-pressed film, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com