A method for producing energy-saving cold-rolled threaded steel bars for construction

A technology of threaded steel bars and production methods, applied in the direction of metal rolling, etc., to achieve the effects of good market application prospects, reduced resource occupation, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

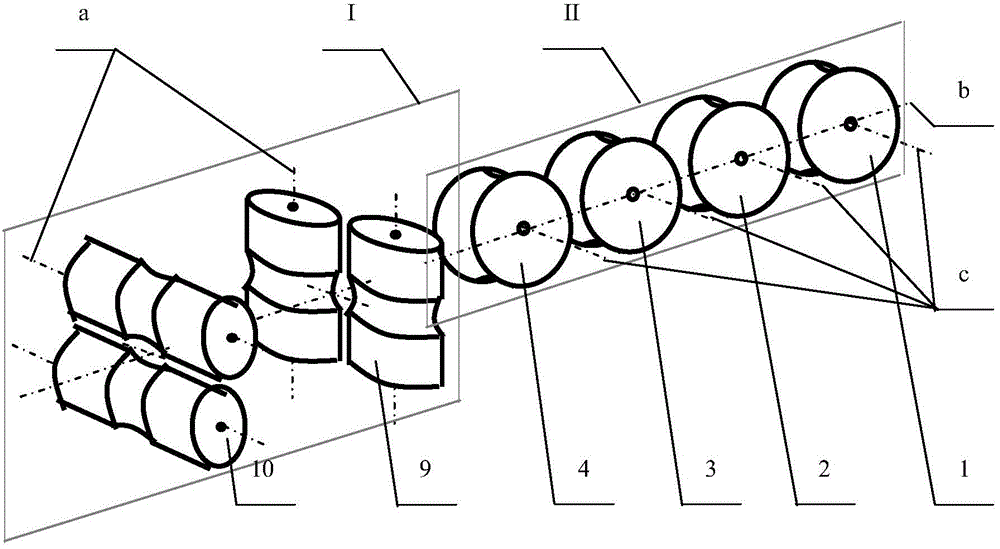

[0020] Taking the Q235 cold-rolled rebar with a diameter of 12mm as an example, the diameter of the round billet is 15.5mm, and the arrangement of the bending rolls is as follows: figure 1 Way. The performance of the rolled rebar was tested, and the results are shown in Table 1.

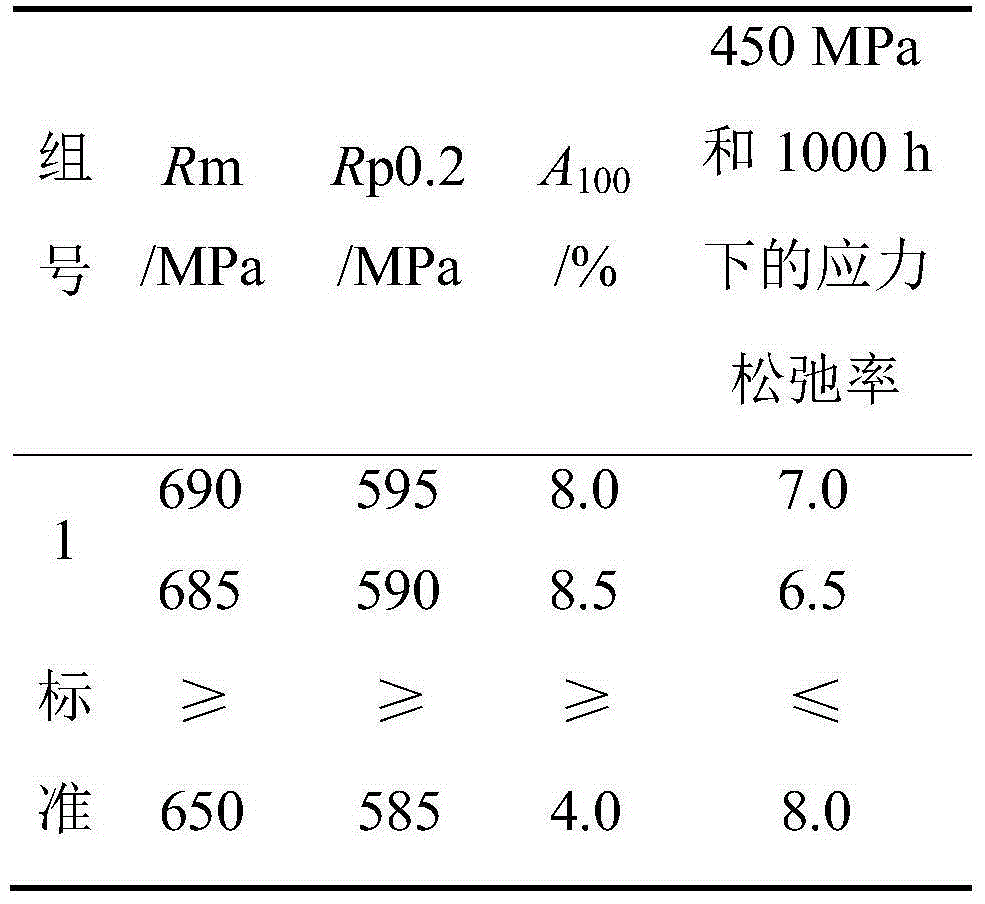

[0021] Table 1 Performance comparison of cold-rolled ribbed rebar with a diameter of 12 mm

[0022]

Embodiment 2

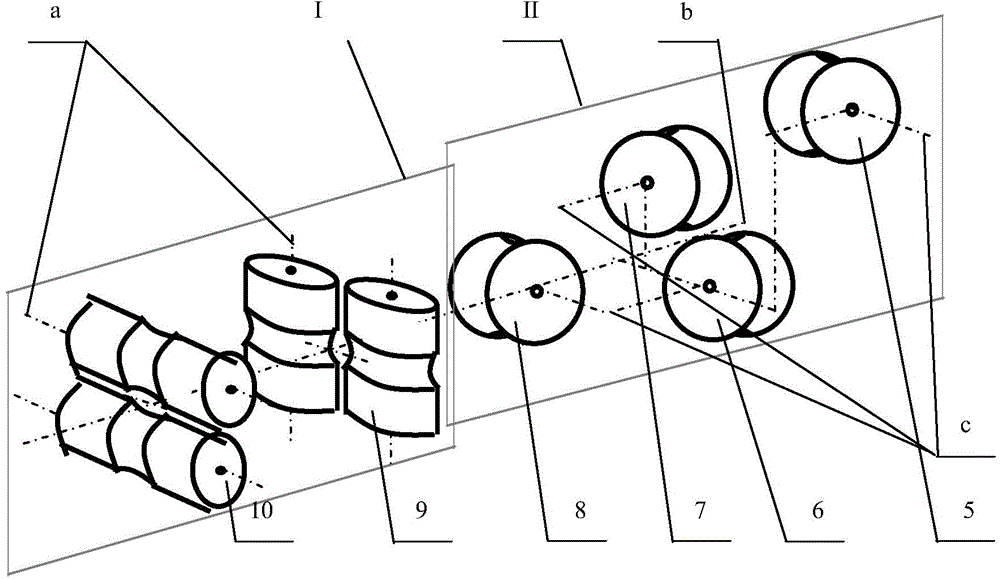

[0024] Taking the Q235 cold-rolled rebar with a diameter of 8mm as an example, the diameter of the round billet is 10.5mm, and the arrangement of the bending rolls is as follows: figure 2 Way. The performance of the rolled rebar was tested, and the results are shown in Table 2.

[0025] Table 2 Performance comparison of 8mm diameter cold-rolled ribbed rebar

[0026]

[0027] [Note] Group 1 in Table 1 is the cold-rolled threaded steel bar produced by this technology, and there is no similar product in the market. Group 1 in Table 2 is the cold-rolled rebar produced by this technology, and group 2 is the cold-rolled ribbed rebar of the same specification in the market. Table 2 Since the tensile strength of products of the same specification on the market has not reached above 650MPa, the stress relaxation rate test under 450MPa and 1000h was not carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com