Mold-picking material for dental denture and preparation method thereof

A technology for dentures and dentistry, applied in the field of dental denture moulding materials, can solve the problems of easily damaged plaster moulds, moulding time and moulding height, poor plaster strength and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

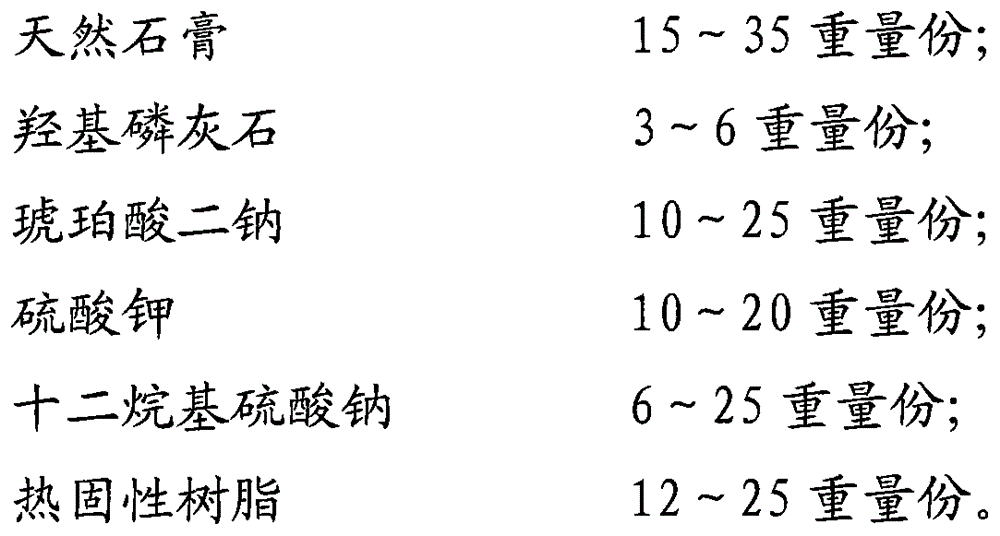

[0019] Embodiment 1 provides a kind of impression material that is used for dental denture, is made of the following components of weight ratio:

[0020]

[0021] A method for preparing an impression material for dental dentures, comprising the following steps:

[0022] Step 1, mixing step: mix and grind natural gypsum, hydroxyapatite, then add and mix disodium succinate;

[0023] Step 2, pressurized firing: pressurize and fire the mixture obtained by said mixing step; at 20Kg / cm 2 The mixture obtained through the mixing step was pressurized for 24 hours under pressure, and the mixture was fired at a temperature of 150°C.

[0024] Step 3, grinding: adding thermosetting resin, potassium sulfate and sodium lauryl sulfate to the product obtained through the pressure firing step, and grinding. Preferably, the size of the ground product in step 3 is 0.3mm-0.5mm.

[0025] The Young's modulus reflects the rigidity of the material. The larger the Young's modulus, the less prone ...

Embodiment 2

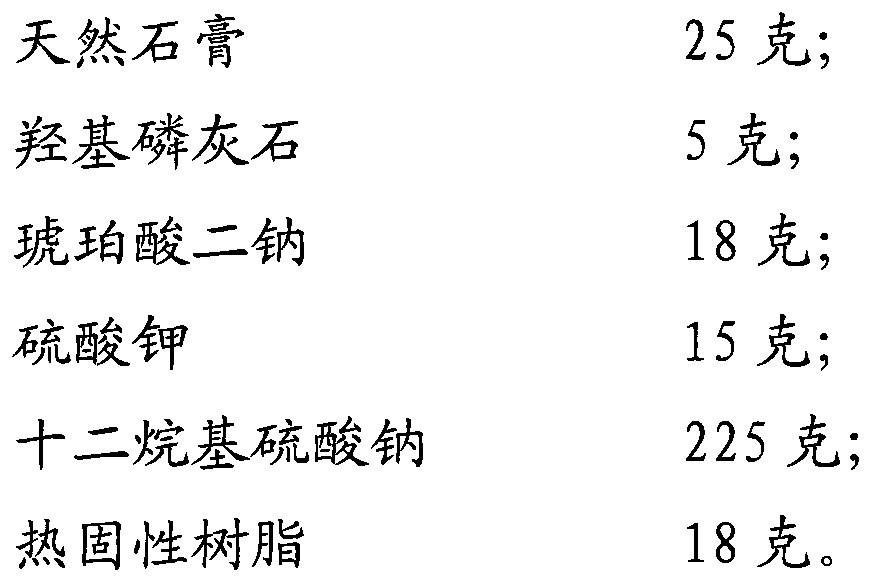

[0027] Embodiment 2 provides a kind of impression material that is used for dental denture, is made of the following components of weight ratio:

[0028]

[0029] A method for preparing an impression material for dental dentures, comprising the following steps:

[0030] Step 1, mixing step: mix and grind natural gypsum, hydroxyapatite, then add and mix disodium succinate;

[0031] Step 2, pressurized firing: pressurize and fire the mixture obtained by said mixing step; at 15Kg / cm 2 The mixture obtained through the mixing step was pressurized for 24 hours under pressure, and the mixture was fired at a temperature of 100°C.

[0032] Step 3, grinding: adding thermosetting resin, potassium sulfate and sodium lauryl sulfate to the product obtained through the pressure firing step, and grinding. Preferably, the size of the ground product in step 3 is 0.3mm-0.5mm.

[0033] The Young's modulus reflects the rigidity of the material. The larger the Young's modulus, the less prone ...

Embodiment 3

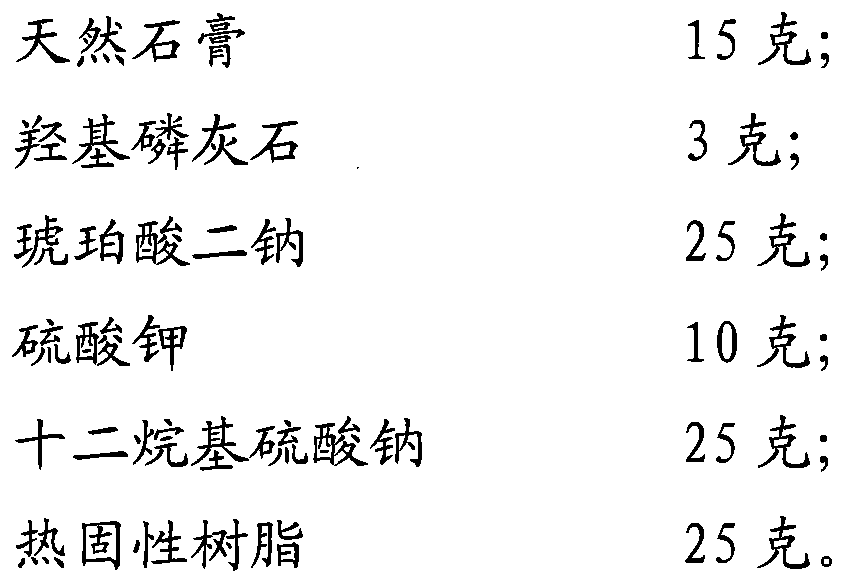

[0035] Embodiment 3 provides a kind of impression material that is used for dental denture, is made of the following components of weight ratio:

[0036]

[0037] A method for preparing an impression material for dental dentures, comprising the following steps:

[0038] Step 1, mixing step: mix and grind natural gypsum, hydroxyapatite, then add and mix disodium succinate;

[0039] Step 2, pressurized firing: pressurize and fire the mixture obtained by said mixing step; at 30Kg / cm 2 The mixture obtained through the mixing step was pressurized for 24 hours under pressure, and the mixture was fired at a temperature of 200°C.

[0040] Step 3, grinding: adding thermosetting resin, potassium sulfate and sodium lauryl sulfate to the product obtained through the pressure firing step, and grinding. Preferably, the size of the ground product in step 3 is 0.3mm-0.5mm.

[0041] The Young's modulus reflects the rigidity of the material. The larger the Young's modulus, the less prone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com