Preparation method of high resilience chlorine-resistant spandex fiber and its application in diapers

A technology of spandex fiber and high resilience, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, and single-component synthetic polymer rayon. Effect of improving creep resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

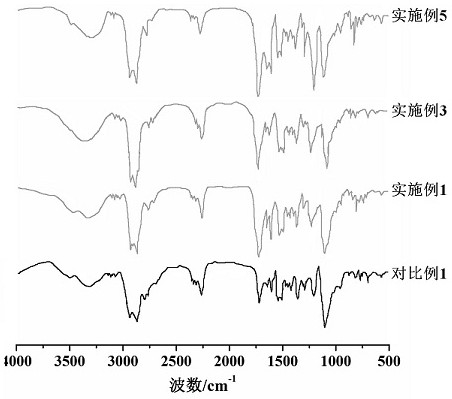

Image

Examples

Embodiment 1

[0037] A kind of preparation of high resilience chlorine-resistant spandex fiber:

[0038] Heat and melt polyester polyol and isocyanate, degassing treatment at 85°C and vacuum degree -0.10MPa respectively, after mixing, put them into a twin-screw extruder under the protection of nitrogen, control the temperature at 123°C, and react for 40 minutes to obtain the pre- Polymer;

[0039] Then add chain extender and additives, control the temperature at 195°C, react for 1min, then pelletize, dry, and ripen at 95°C to obtain polyurethane slices;

[0040] The above-mentioned dried polyurethane chips are melted and mixed evenly with a chlorine-resistant crosslinking agent, melt-extruded, spun and formed, and then aged at 95°C for 52 hours to obtain a high-resilience chlorine-resistant spandex fiber.

[0041] Among them, the molar ratio of polyester polyol, isocyanate and chain extender is 4.7:1:0.29; the amount of additive added is 1.3wt% of the total amount of polyester polyol, isoc...

Embodiment 2

[0045] The difference between the preparation of a kind of high resilience chlorine-resistant spandex fiber and embodiment 1 is:

[0046] The molar ratio of polyester polyol, isocyanate and chain extender is 5.6:1:0.38; the amount of additive added is 1.6wt% of the total amount of polyester polyol, isocyanate and chain extender; the amount of chlorine-resistant crosslinking agent added It is 4.1wt% of polyurethane chips; ethylenediamine, ethanolamine and 4,11-diamino-2-(3-methoxypropyl)-1H-naphtho[2,3-F]isoindol in the chain extender The molar ratio of indole-1,3,5,10(2H)-tetraketone is 7.3:0.77:2.1; the additives are titanium dioxide, antioxidant Tinuvin 622, UV stabilizer Tinuvin 234 and magnesium stearate, and the mass ratio of the four is 1:1.2:1:0.25.

[0047] The preparation of chlorine-resistant cross-linking agent is the same as in Example 1.

Embodiment 3

[0049] The difference between the preparation of a kind of high resilience chlorine-resistant spandex fiber and embodiment 1 is:

[0050] 4,11-diamino-2-(3-methoxypropyl)-1H-naphtho[2, 3-F]isoindole-1,3,5,10(2H)-tetraone.

[0051] The preparation of chlorine-resistant cross-linking agent is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com