Rock-like material tension-shear and biaxial tension-compression testing device and use method thereof

A test device, rock technology, applied in the field of rock and soil mechanics, to achieve the effect of easy control, simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment discloses a rock material tension-shear and biaxial tension-compression test device, including frame I1, frame II2, upper platen 3, slider I4, slider II40, backing plate 6, testing machine loading head I91, testing machine Loading head II92, testing machine loading head III93 and testing machine loading head IV94.

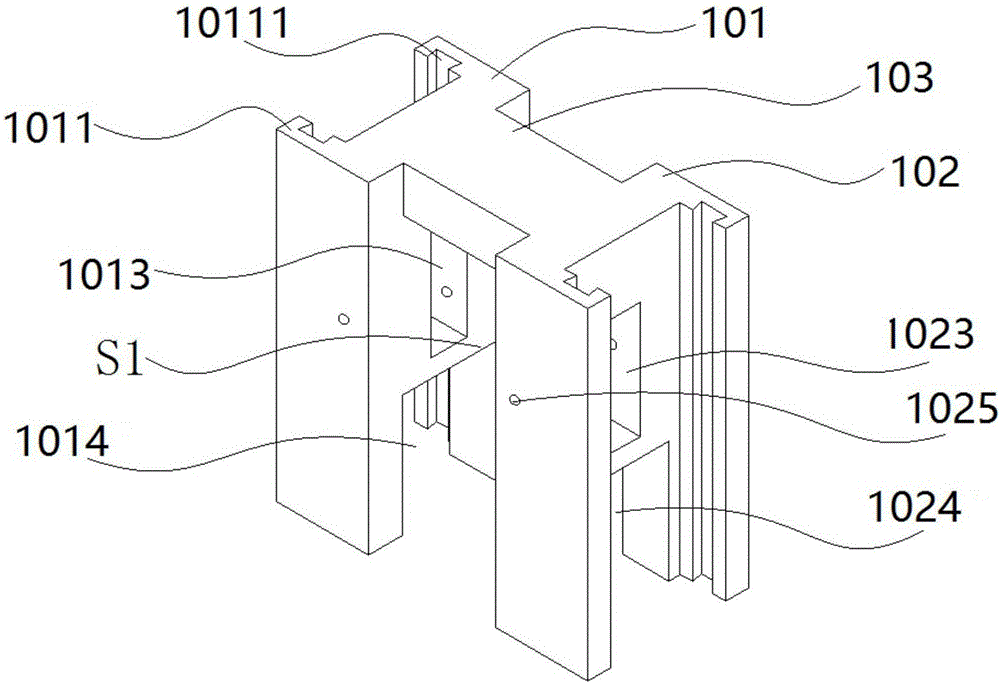

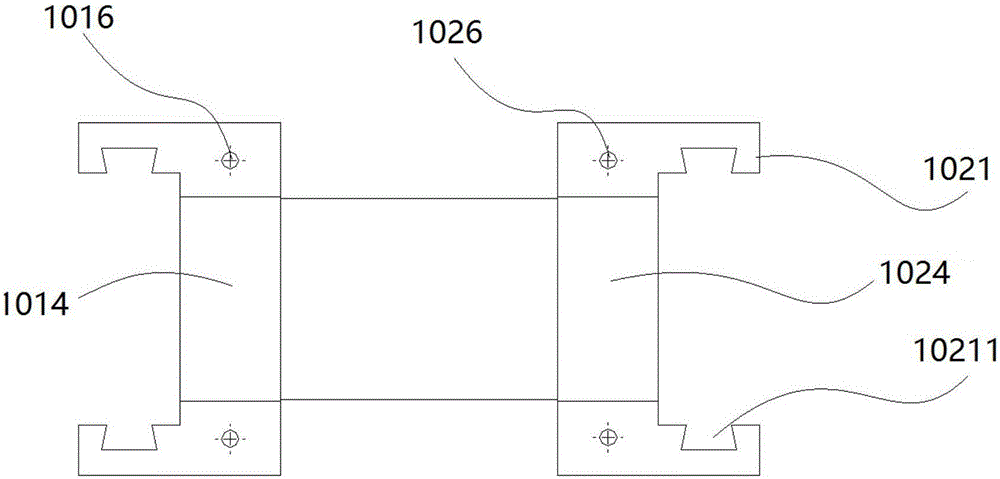

[0062] see image 3 and Figure 4 , the frame I1 includes a column I101, a column II102 and a beam I103. The beam I 103 is connected between the column I 101 and the column II 102, and the bottom surfaces of the three are flush. The column I101, column II102 and beam I103 enclose a semi-enclosed space IS1. The column I101, column II102 and beam I103 enclose shape. The column I 101, the column II 102 and the beam I 103 are integrated.

[0063] A cuboid A is removed from the bottom surface of the column I101 to form a gap I1014. The gap I1014 runs through both sides of the column I101. An outlet of the notch I1014 is in the semi-enclos...

Embodiment 2

[0083] This embodiment discloses a biaxial tension-compression test method using the rock material tension-shear and biaxial tension-compression test device described in Embodiment 1, comprising the following steps:

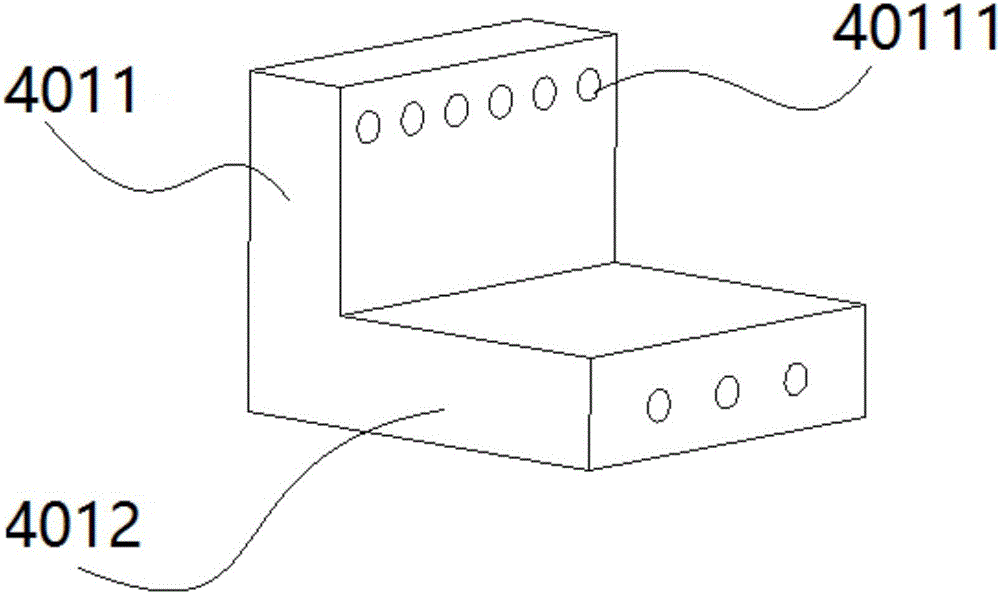

[0084] 1) Align the right-angle plate I401 and the right-angle plate II4001 with the sample 8, and use superglue to paste the horizontal plate I4012 and the horizontal plate II40012 respectively on the upper and lower surfaces of the sample 8 to form an assembly.

[0085] 2) After the superglue is completely solidified, place the assembly in the space IS. Install the slider I4 and the slider II40 on the beam I103 and the beam II203 respectively: install the roller shaft I404 first, and then connect the right-angle plate I401 and the side plate I402 with bolts and reducing bolts I403. Install the roller shaft II4004 first, and then connect the right-angle plate II4001 and the side plate II4002 with bolts and reducing bolts II4003.

[0086] 3) Install side pressur...

Embodiment 3

[0090] This embodiment discloses a tensile-shear test method using the rock material tensile-shear and biaxial tensile-compression test device described in Embodiment 1, comprising the following steps:

[0091] 1) Align the right-angle plate I (401) and right-angle plate II (4001) with the sample (8), and use super glue to paste the horizontal plate I (4012) and the horizontal plate II (40012) on the upper and lower surfaces of the sample (8). , forming an assembly;

[0092] 2) After the superglue is completely solidified, place the assembly in space I (S); install slider I (4) and slider II (40) on beam I (103) and beam II (203) respectively : Install the roller shaft I (404) first, then connect the right-angle plate I (401) and the side plate I (402) with bolts and reducing bolts I (403); install the roller shaft II (4004) first, then use bolts and variable diameter bolts The diameter bolt II (4003) connects the right-angle plate II (4001) and the side plate II (4002);

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com