Preparation method of polyimide film and polyimide film

A technology of polyimide film and polyamic acid resin, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of unfavorable popularization and application, mechanical and thermal performance decline, rough surface of the film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The application provides a kind of preparation method of polyimide film, comprises the following steps:

[0026] S1: Prepare a thermally conductive filler dispersion, mix the clay treated with the first silane coupling agent and the nano-scale inorganic filler treated with the second silane coupling agent in a solvent to form a thermally conductive filler dispersion, and the particle size of the clay is Micron;

[0027] S2: Add diamine monomer and dianhydride monomer to the thermally conductive filler dispersion to generate a polyamic acid resin solution; the thermally conductive filler dispersion forms a thermally conductive filler structure with a three-dimensional network structure in the polyamic acid resin solution ;

[0028] S3: Casting the polyamic acid resin solution to obtain a polyimide film through imidization and biaxial stretching.

[0029] Another object of the present application is to provide a polyimide film, which is prepared using the above-mentione...

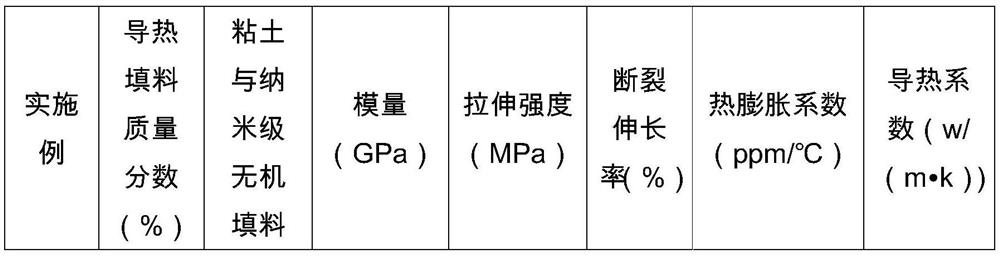

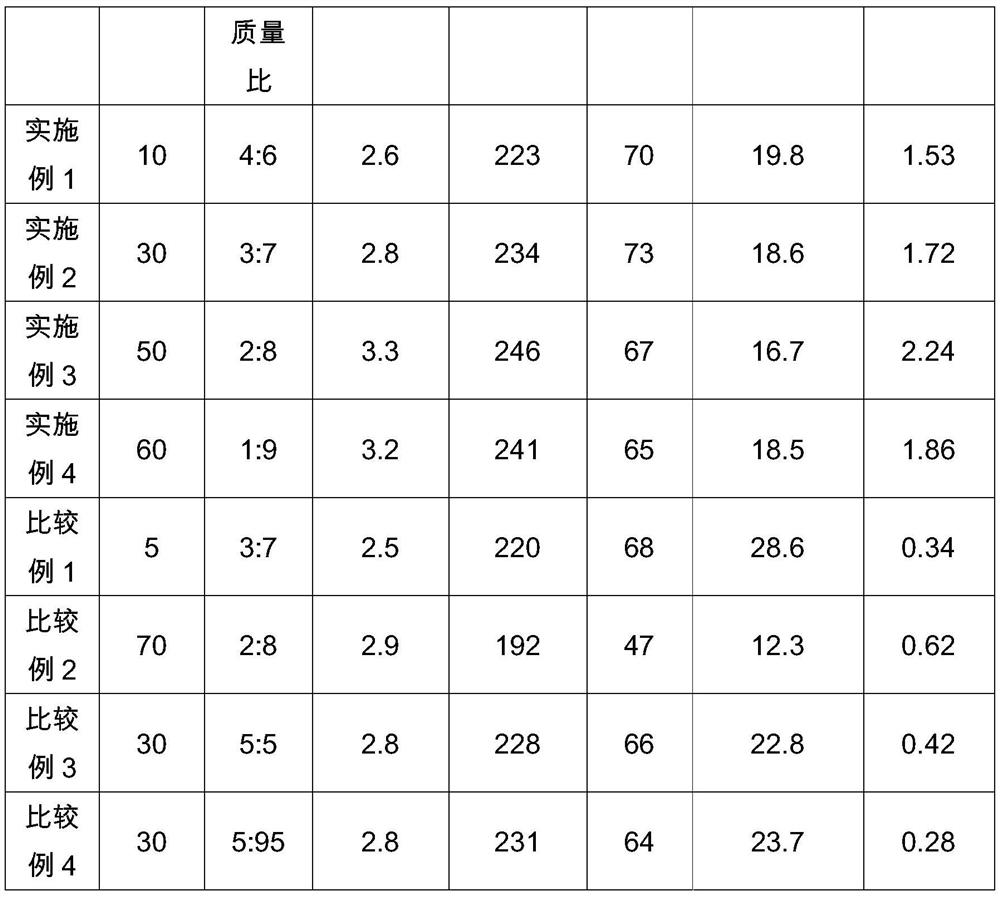

Embodiment 1

[0050] Take a total of 41.8 g of montmorillonite treated with a silane coupling agent and aluminum nitride nanoscale inorganic fillers modified by a silane coupling agent, wherein the particle size of the montmorillonite is 10 μm, and the nanoscale inorganic filler The particle size is 300nm, and the mass ratio of montmorillonite and aluminum nitride is 4:6, and montmorillonite and aluminum nitride nanoscale inorganic filler are added to 2.1kg of N,N-dimethylformamide at the same time , and after ultrasonic dispersion for 1 h, a uniform and stable thermally conductive filler dispersion was obtained.

[0051] 200.2 g of 4,4'-diaminodiphenyl ether and 218 g of pyromellitic dianhydride were added to the thermally conductive filler dispersion, and a polyamic acid resin solution was obtained after 2 hours of reaction.

[0052] After the polyamic acid resin solution is degassed in vacuum, 204.2g of acetic anhydride and 25.8g of isoquinoline are added thereto, and the polyamic acid r...

Embodiment 2

[0054] A total of 125.5 g of mica treated with a silane coupling agent and boron nitride nano-scale inorganic fillers modified with a silane coupling agent were used, wherein the particle diameter of the mica was 10 μm, and the particle size of the boron nitride nano-scale inorganic fillers was The diameter is 300nm, and the mass ratio of mica and boron nitride is 3:7. Add mica and boron nitride nano-scale inorganic fillers to 2.1kg of N,N-dimethylformamide at the same time, and disperse them by ultrasonic for 1h , to obtain a uniform and stable dispersion of thermally conductive fillers.

[0055] 200.2 g of 4,4'-diaminodiphenyl ether and 218 g of pyromellitic dianhydride were added to the thermally conductive filler dispersion, and a polyamic acid resin solution was obtained after 2 hours of reaction.

[0056] After the polyamic acid resin solution is degassed in vacuum, 204.2g of acetic anhydride and 25.8g of isoquinoline are added thereto, and the polyamic acid resin soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com