Biaxial fatigue test clamp

A biaxial fatigue test and fixture technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of high cost, increase the complexity of the test system, and poor versatility, and achieve The structure is simple, the structure is clear, and the effect of avoiding synchronization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

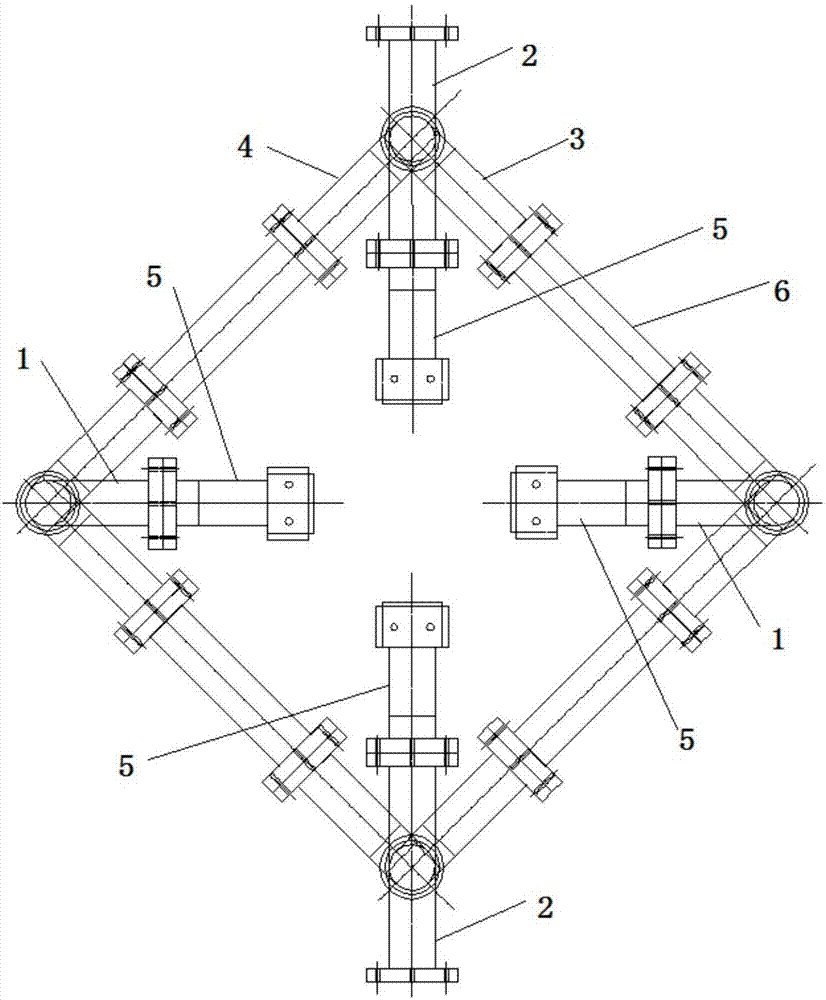

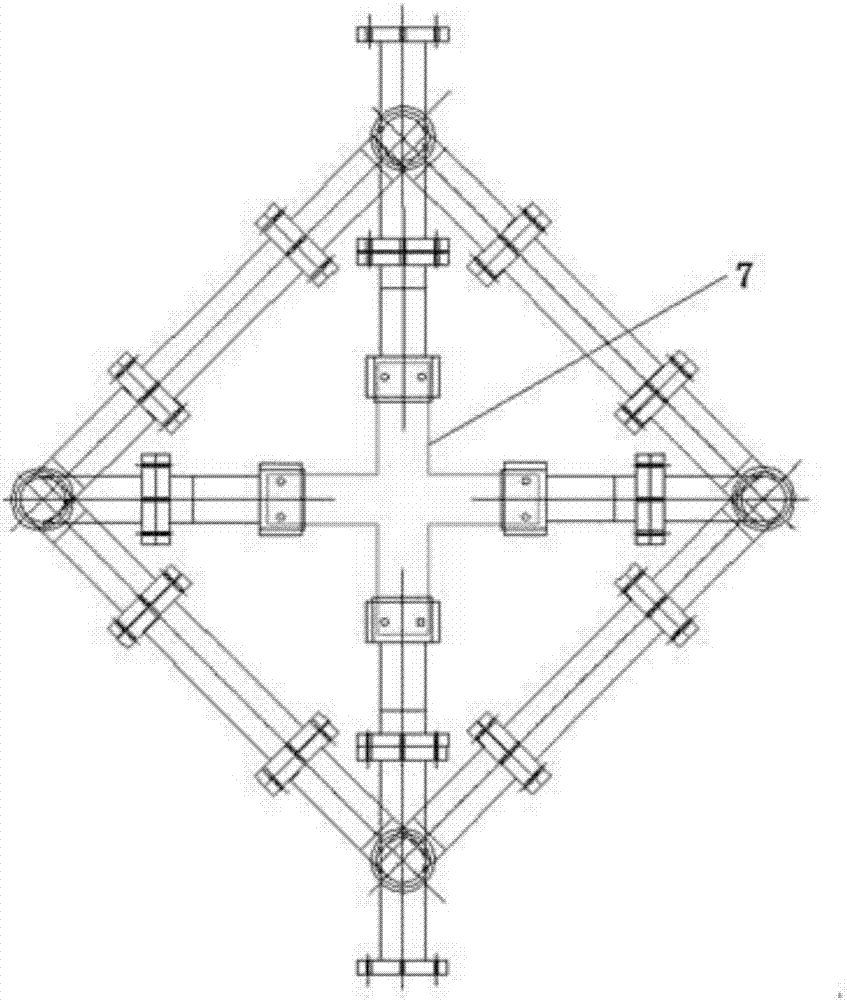

[0023] refer to Figure 1-Figure 2 , the present invention consists of two pivoting arms 3, 4 movably connected to a T-shaped bracket 1 or a cross-shaped bracket 2 to form a T-shaped clamp joint and a cross-shaped clamp joint, and two T-shaped clamp joints and two cross-shaped clamp joints The rotating arms are connected end to end to form a movable quadrilateral frame. The cross-shaped clamp joints are located at the upper and lower ends, and the T-shaped clamp joints are located at the left and right ends. The four clamp joints are respectively connected to a clamp chuck 5, and the other end of the cross-shaped clamp joint is connected to the single shaft. In the fatigue testing machine, sample 7 is connected to four clamps 2 respectively. An extension rod 6 is connected between the connecting arms on each frame of the quadrilateral frame to suit the size of different samples.

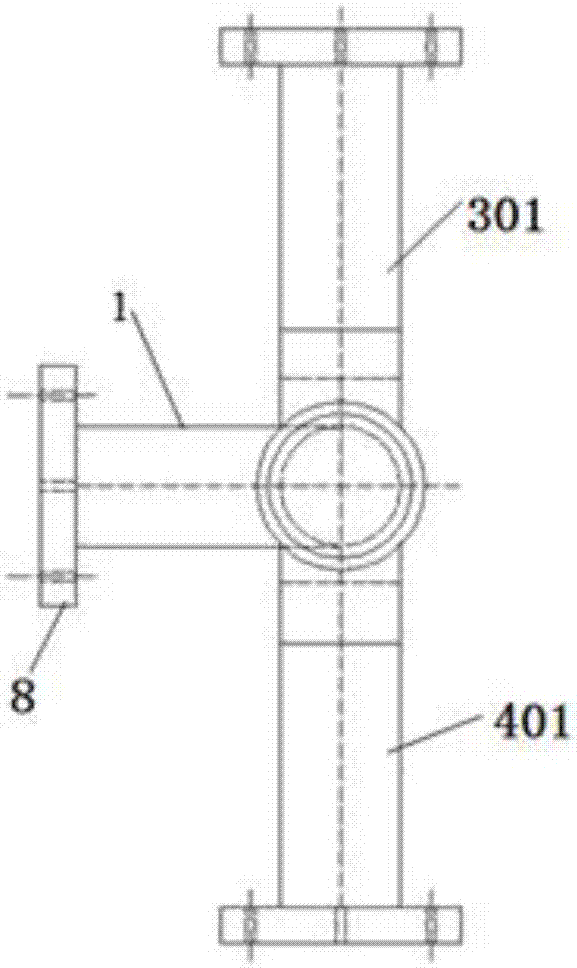

[0024] refer to image 3 , Figure 4 , the T-shaped fixture joint is composed of a T-shaped br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com