Continuous polyethylene dissolving process in a double screw extructor to prepare lithium ion cell diaphragm

A technology of twin-screw extruder and lithium-ion battery, which is applied in the direction of secondary battery parts, etc., can solve the problems of uneven micropores and uneven dissolution of the diaphragm, and achieve the effect of uniform hole shape, good strength and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

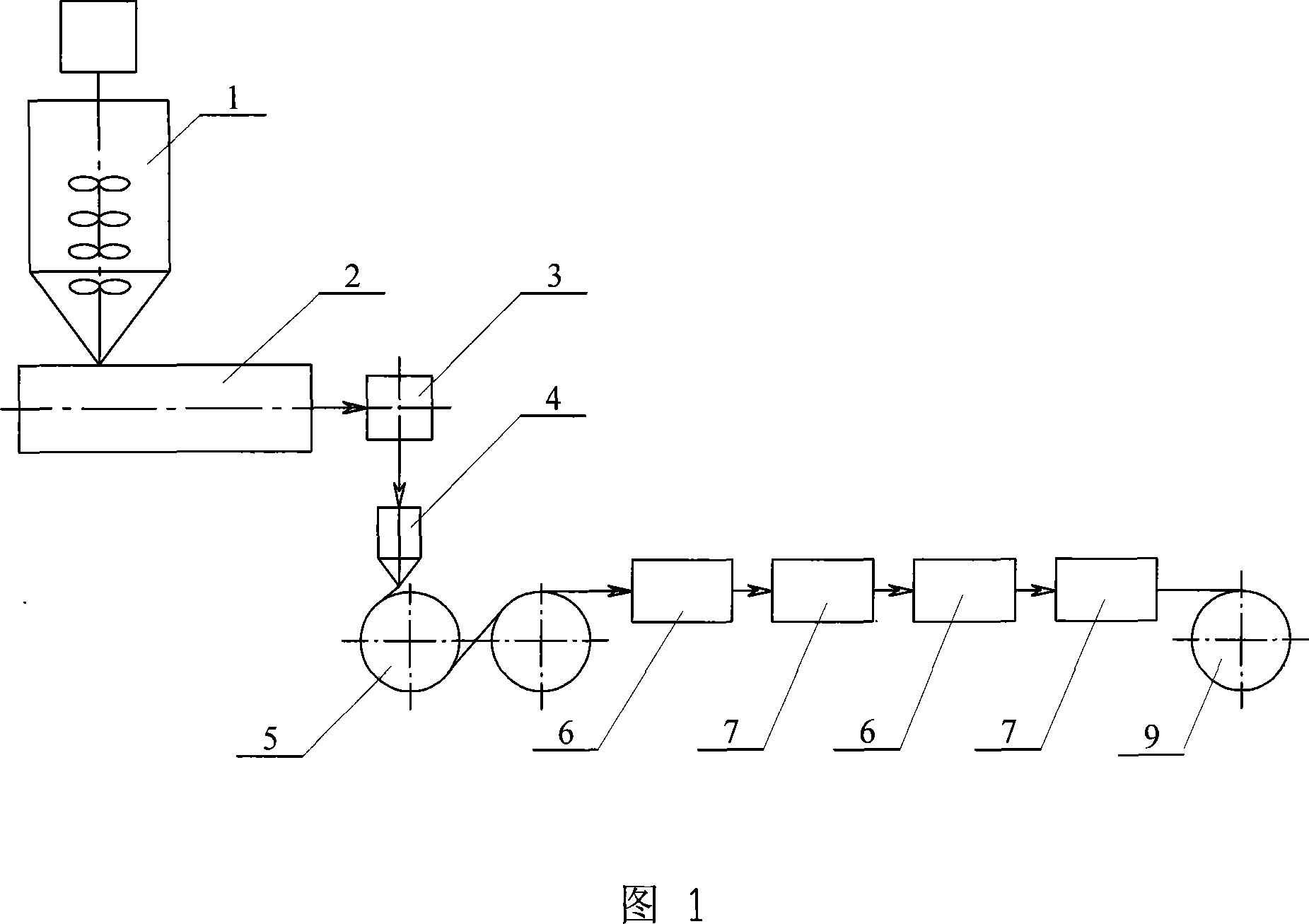

[0007] Specific Embodiment 1: The steps of the method for preparing lithium-ion battery separators in this embodiment are as follows: 1. Add ultra-high molecular weight polyethylene, high-density polyethylene and mineral oil together in the continuous batching and feeding kettle 1, at 10 to 60 rpm Mix the raw materials evenly, wherein the mass ratio of ultra-high molecular weight polyethylene and high-density polyethylene is 1:1-15, and the mass ratio of the total mass of ultra-high molecular weight polyethylene and high-density polyethylene to mineral oil 1:5-15; 2. The mixture is continuously added to the twin-screw extruder 2; under the condition of 40-240°C, the ultra-high molecular weight polyethylene and high-density polyethylene are continuously dissolved in the twin-screw extruder 2 Mineral oil, then continuously extruded by twin-screw extruder 2 at a speed of 50 to 250 rpm; 3. The mixture is 1 according to the mass ratio of the total mass of ultra-high molecular weight...

specific Embodiment approach 2

[0010] Specific embodiment 2: In this embodiment, in step 1, the molecular weight of the ultra-high molecular weight polyethylene is 1 million to 8 million. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: In this embodiment, in step one, the molecular weight of the ultra-high molecular weight polyethylene is 4.5 million. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com