Biomorphic hierarchical porous La0.9K0.1CoO3 catalyst and preparation method thereof

A biomorphic, multi-level pore technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve catalyst shedding, specific surface area and catalytic activity reduction, Catalyst coating problems and other problems, to achieve the effect of complete pore channels, low preparation cost, and uniform pore shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

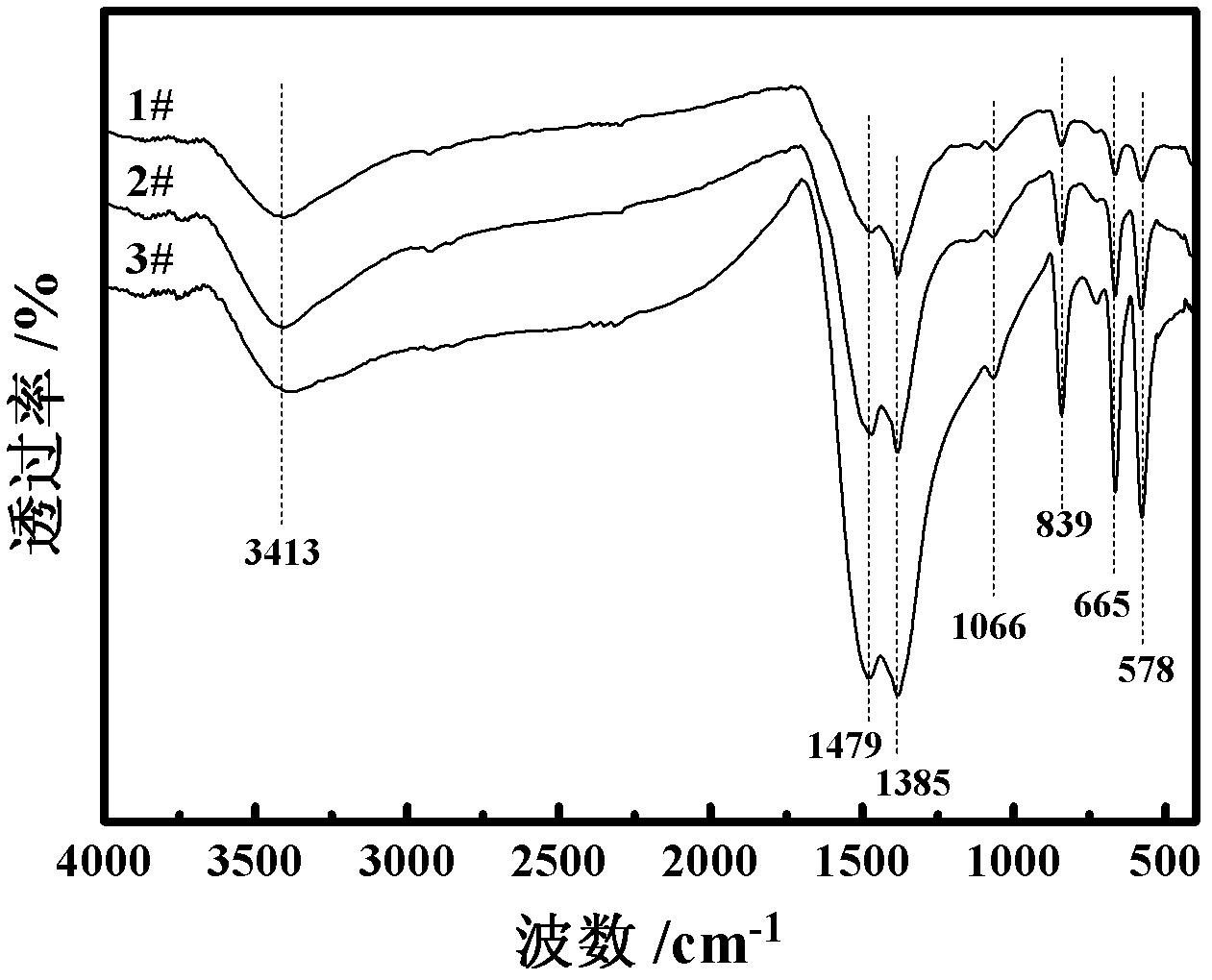

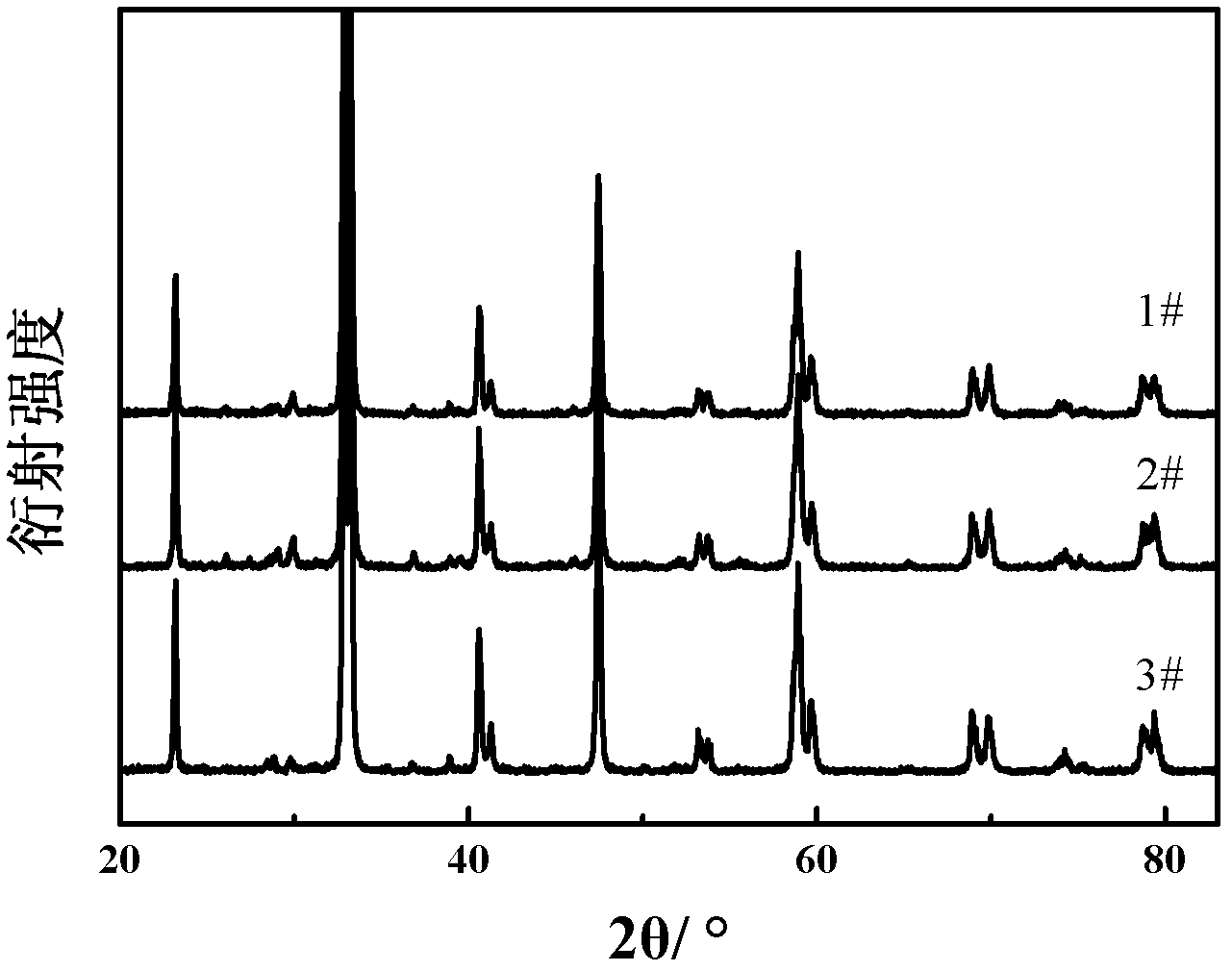

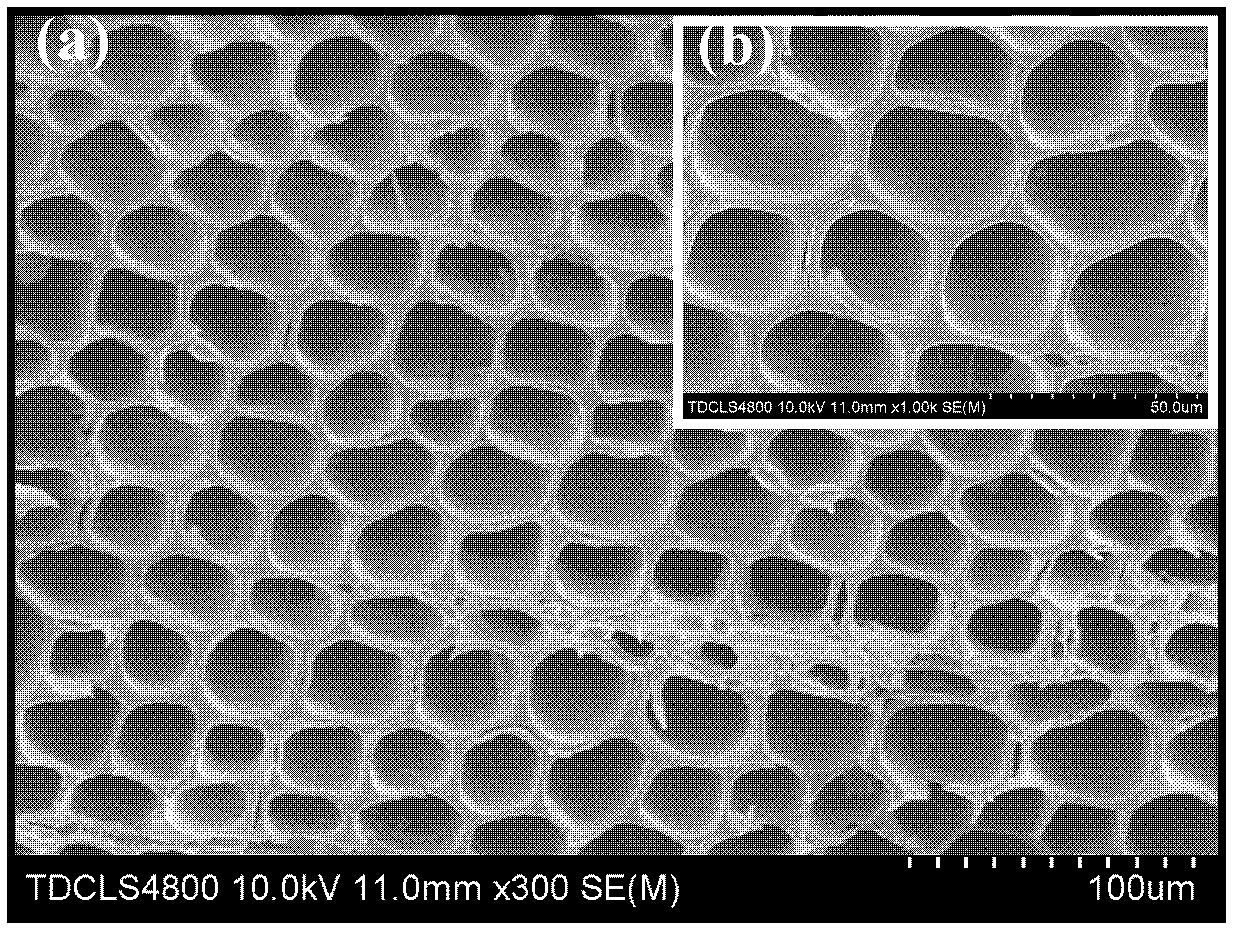

[0030] Weigh 12.9906g La(NO 3 )·6H 2 O, 0.3271g CH 3 COOK, 8.3030g Co(CH 3 COO) 2 4H 2 O and 13.2113 g of glucose were dissolved in 100 ml of deionized water. In a water bath at 60°C for 70h, after cooling, La 0.9 K 0.1 CoO 3 Sol.

[0031] The pine block is cut into length: width: height = 40mm: 30mm: 10mm, dried at 100°C for 24h, soaked in a mixed solution with acetone / ethanol volume ratio of 3 for 4 days, then dried at 80°C for 5 days; The pine blocks were continuously impregnated in La 0.9 K 0.1 CoO 3 After five days in the sol solution, the surface was cleaned with distilled water and dried at 60°C for three days.

[0032] The impregnated pine wood block was pyrolyzed under flowing argon. Firstly, the temperature was raised to 120°C at a rate of 3°C / min, and kept at a temperature of 30 minutes. Raise the temperature to 800 °C at a rate of 10 °C / min, keep it for 3 hours, and then cool to room temperature with the furnace to obtain the NO x The conversion effic...

Embodiment 2

[0034] Weigh 12.9906g La(NO 3 )·6H 2 O, 0.3271g CH 3 COOK, 8.3030g Co(CH 3 COO) 2 4H 2 O and 13.2113 g of glucose were dissolved in 100 ml of deionized water. In a water bath at 70°C for 50h, after cooling, La 0.9 K 0.1 CoO 3 Sol.

[0035] The pine block is cut into length: wide: high=40mm: 30mm: 10mm, dried at 120°C for 24h, boiled in 5wt.% ammonia solution for 8h, then dried the treated pine block at 50°C for 3 days; then Continuous impregnation of treated pine blocks in La 0.9 K 0.1 CoO 3 After 6 days in the sol solution, the surface was cleaned with distilled water and dried at 80°C for 2 days.

[0036] The impregnated pine wood block was pyrolyzed under flowing argon. Firstly, the temperature was raised to 110°C at a rate of 2°C / min, and kept at a temperature of 40 minutes. Then, the temperature was raised to 450°C at a rate of 3°C / min. Raise the temperature to 700 °C at a rate of 10 °C / min, keep it for 3 hours, and then cool to room temperature with the furn...

Embodiment 3

[0038] Weigh 12.9906g La(NO 3 )·6H 2 O, 0.3271g CH 3 COOK, 8.3030g Co(CH 3 COO) 2 4H 2 O and 13.2113 g of glucose were dissolved in 100 ml of deionized water. In a water bath at 50°C for 60h, after cooling, La 0.9 K 0.1 CoO 3 Sol.

[0039] The pine blocks were cut into length: width: height = 40mm: 30mm: 10mm, dried at 120°C for 24 hours, and the pine blocks without any pretreatment were continuously impregnated in La 0.9 K 0.1 CoO 3 Sol diluted solution for 3 days, the surface was cleaned with distilled water, and dried at 50°C for 4 days.

[0040] The impregnated pine wood block was pyrolyzed under flowing argon. First, the temperature was raised to 130°C at a rate of 4°C / min, and kept for 35 minutes, then raised to 350°C at a rate of 1°C / min, and kept for 3 hours. Raise the temperature to 900°C at a rate of 8°C / min, hold for 2 hours, and then cool to room temperature with the furnace to obtain the NO x The conversion efficiency of the hierarchically porous La w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com