Preparation method of glass micro-pore channel and use of it to separate alkali metal ions

An alkali metal ion, glass technology, applied in glass manufacturing equipment, glass forming, glass re-molding and other directions, can solve the problems of low promotion value, large size, poor sensitivity, etc. The effect of a short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

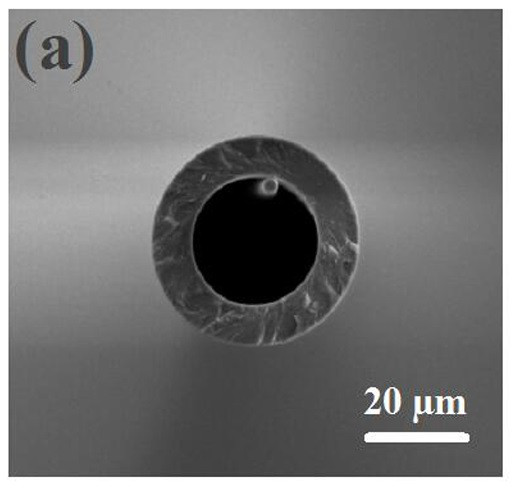

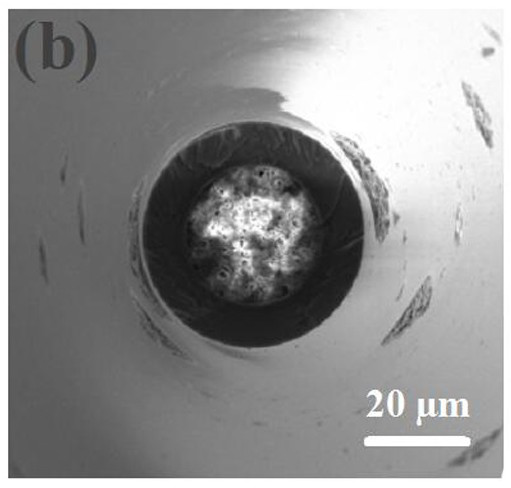

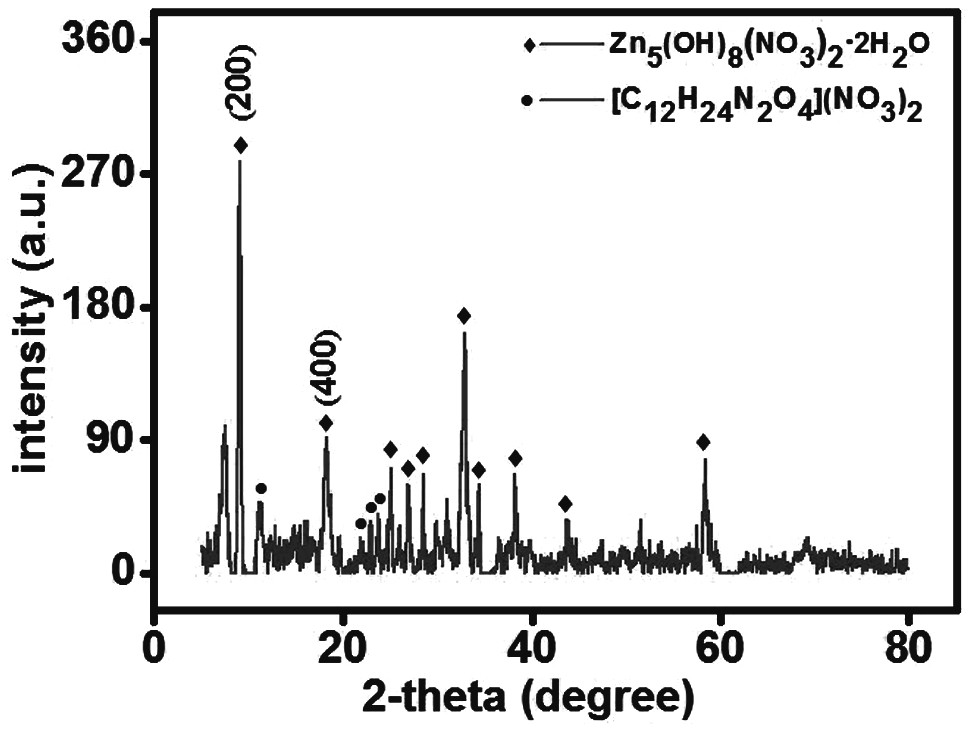

[0054] like Figure 1a , 1b shown, specific: Z 5 HN@DAC 12 N 4 O 10 The preparation method of composite-modified glass micro-channels and the method for separating alkali metal ions by using the same, comprising the following steps:

[0055] Step 1: Preparation of glass micro-channels;

[0056] Step 2: Prepared to react to generate Z 5 HN@DAC 12 N 4 O 10 A, B solution of the complex, wherein, A solution is a solution of 4,13-diaza-18-crown-6, B solution is a solution of zinc nitrate hexahydrate,

[0057] Step 3: Prepare Z 5 HN@DAC 12 N 4 O 10 Composite-modified glass microchannels;

[0058] A certain volume of solution A is injected into the tail of the glass micro-tube prepared in step 1 using an injection needle, then insert the glass micro-tube into which solution A has been injected into solution B, draw a certain amount of solution B, and let solutions A and B in the glass The tip of the microtube reacts to form Z 5 HN@DAC 12 N 4 O 10 composite to obtain...

Embodiment

[0065] see Figure 4 shown, based on Z 5 HN@DAC 12 N 4 O 10 Preparation method of composite-modified glass microchannels:

[0066] Step 1: Prepare glass micro-channels by P-97 glass drawing instrument;

[0067] Among them, the glass micro-channel drawing conditions parameters are shown in Table 1 below, and the nano-pore size obtained by SEM characterization is about 23 ± 3 μm.

[0068] Table 1. Drawing condition parameters of glass micro-channels

[0069]

[0070]

[0071] Step 2: Prepare Z that can react to form functional Z 5 HN@DAC 12 N 4 O 10 The compound, the operation method is as follows: firstly, 104.9 mg of 4,13-diaza-18-crown-6 was dissolved in 5 mL of dichloromethane and 5 mL of methanol solution and marked as solution A, followed by 185.8 mg of Zn(NO 3 ) 2 ·6H 2 O was dispersed in 10 mL methanol solution as B solution. Then, the A and B solutions were shaken up under an ultrasonic apparatus, and sealed with a sealing film before being placed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com