Pre-coating film and preparation method for the same

A pre-coating, flexible coating technology, applied in chemical instruments and methods, film/flake adhesives, coatings, etc. problem, to achieve the effect of simple operation, lower cost and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

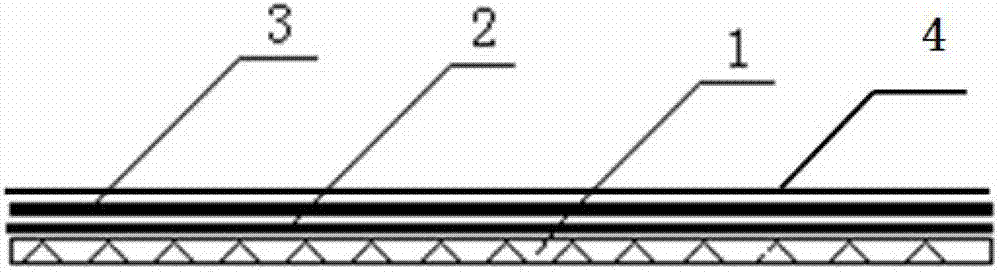

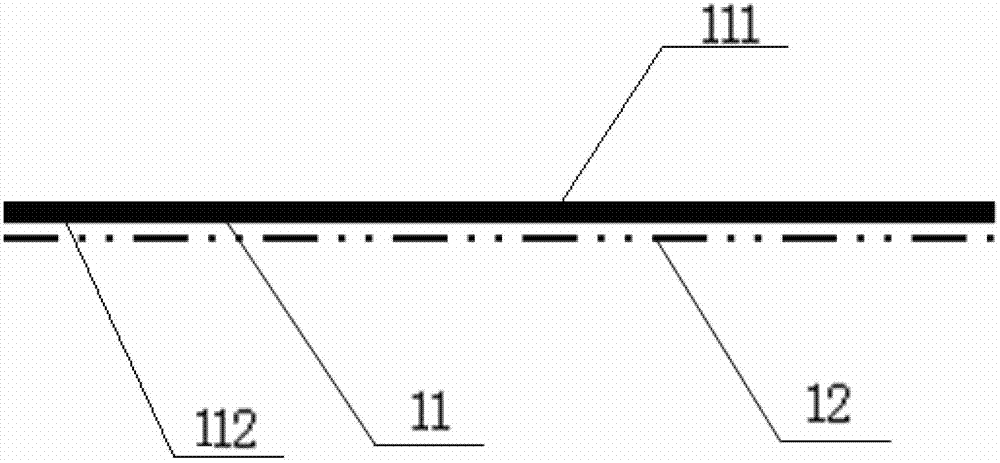

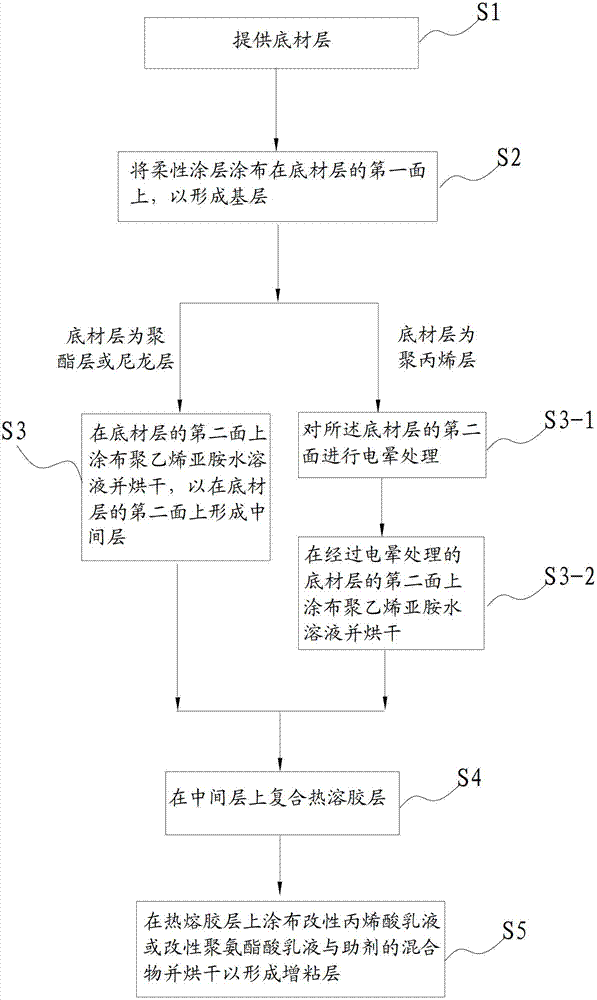

[0066] Such as image 3 As shown, Step 1: provide a biaxially stretched polyester layer or a biaxially stretched nylon layer as the substrate layer 11 .

[0067] Step 2: Coating the flexible coating 12 comprising a mixture of polyurethane dispersion and curing agent on the first surface 111 of the substrate layer 11 by using a coating device to form the substrate 1 .

[0068] Step 3: On the second surface 112 of the substrate layer 11, apply the polyethyleneimine aqueous solution prepared according to the above ratio and dry it with a drying device, so that the polyvinyl chloride imine is solidified on the substrate layer 11 to form the intermediate layer 2 on the second surface 112 of the

[0069] Since the polyester layer and the stretched nylon layer are all polar materials, the intermediate layer 2 can be directly coated on the second surface 112 of the substrate layer 11, and the gap between the second surface 112 and the intermediate layer 2 can be guaranteed after dryi...

Embodiment 2

[0079] The difference between Embodiment 2 of the present invention and Embodiment 1 is that the substrate layer 11 adopts a biaxially stretched polypropylene layer. Since polypropylene is a non-polar material, in order to improve its surface stickability, it can be

[0080] Before step three is implemented, the second surface of the substrate layer 11 is corona treated to obtain a certain amount of polar groups such as carbonyl groups. After the corona treatment, the dyne value of the surface of the second surface 112 of the substrate layer 11 can reach 36 or more.

[0081] The polyethyleneimine aqueous solution is coated on the second surface 112 of the corona-treated substrate layer 11 and dried, and the drying temperature is 85-95°C.

[0082] The other steps in Embodiment 2 are the same as the corresponding steps in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com