Copper alloy plate having excellent anti-stress relaxation properties

A copper alloy plate, stress-resistant technology, applied in the direction of coupling devices, parts of connecting devices, electrical components, etc., can solve the problem that the stress relaxation rate has not been fully improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

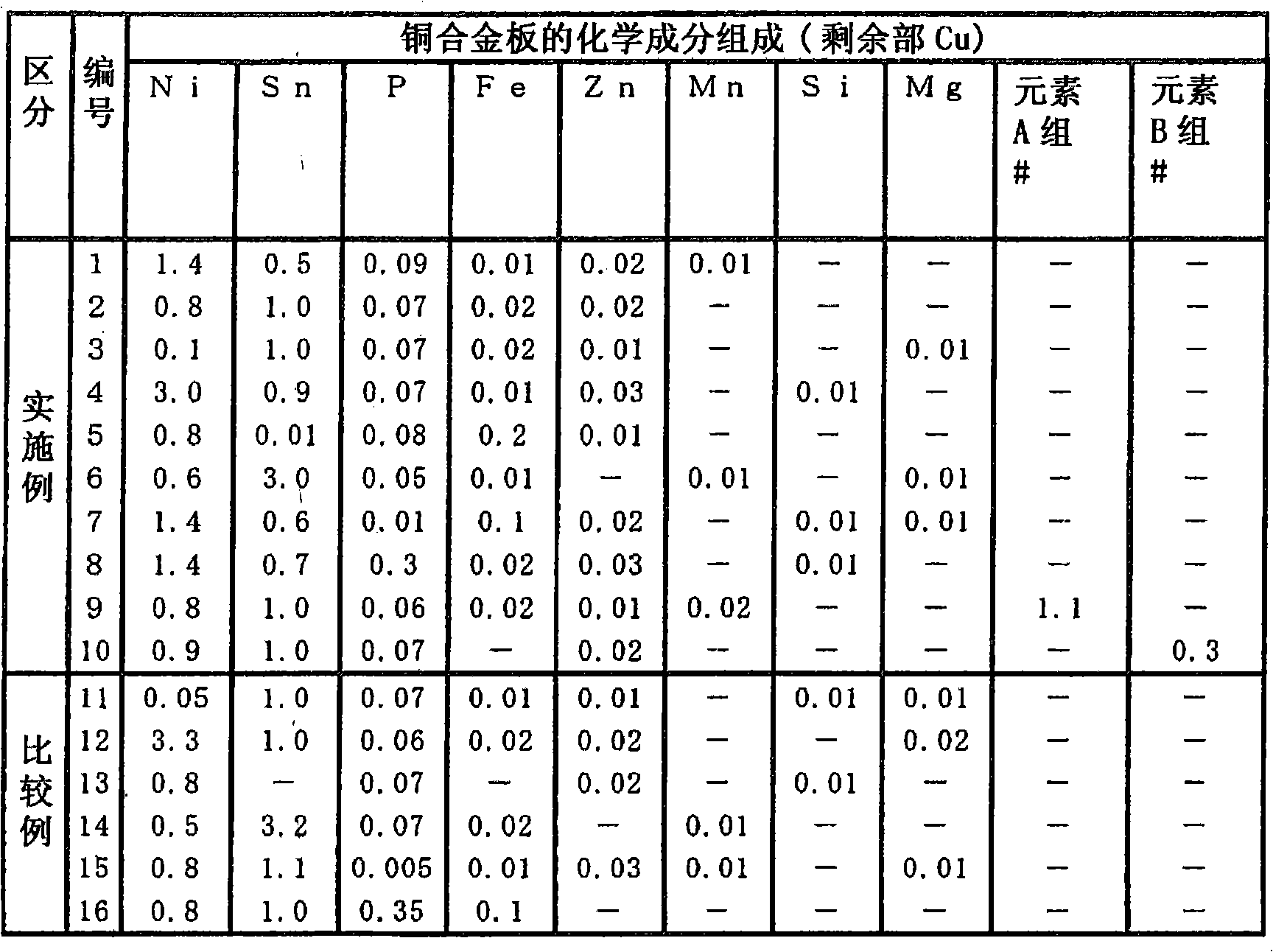

[0097] Embodiments of the present invention will be described below. Copper alloy thin plates having various densities of aggregates of atoms composed of 15 or more and less than 100 atoms specified in the present invention can be produced under the above-mentioned preferred production conditions. Furthermore, various properties such as electrical conductivity, tensile strength, 0.2% proof strength, and stress relaxation resistance of each of these copper alloy thin plates were evaluated.

[0098] Specifically, the copper alloys of the chemical composition shown in Table 1 (the remainder of the element amount is Cu) were melted in a centerless furnace, and then were melted in a semi-continuous casting method (the cooling and solidification speed of casting 2° C. / sec) to obtain an ingot having a thickness of 70 mm×width 200 mm×length 500 mm. These respective ingots were jointly rolled under the following conditions to manufacture copper alloy thin plates. That is, after face-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Endurance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com