Softening-resistant copper alloy and method of forming sheet of the same

a technology of softening resistance and copper alloy, which is applied in the direction of metal rolling arrangements, etc., can solve the problems of inability to achieve the miniaturization, weight reduction and improvement of softening resistance of copper alloy parts, and the high softening resistance intended by the present invention cannot be guaranteed, so as to reduce the dimensional accuracy of parts, reduce the strength, and high softening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0035] Examples of the present invention and comparative examples will be described.

[0036] Copper alloys of chemical compositions shown in Table 1 were melted in a coreless low-frequency induction furnace and copper alloy ingots of 50 mm in thickness, 200 mm in width and 500 mm in length were produced by a semicontinuous casting process. Each of the ingots was heated and the thickness was reduced to 12 mm by hot rolling and the sheet was machined by facing. Then the ingot was processed by a plurality of working cycles each of a cold rolling process and an annealing process, and the sheet was rolled in a copper alloy sheet of about 0.2 mm in thickness by finish cold rolling.

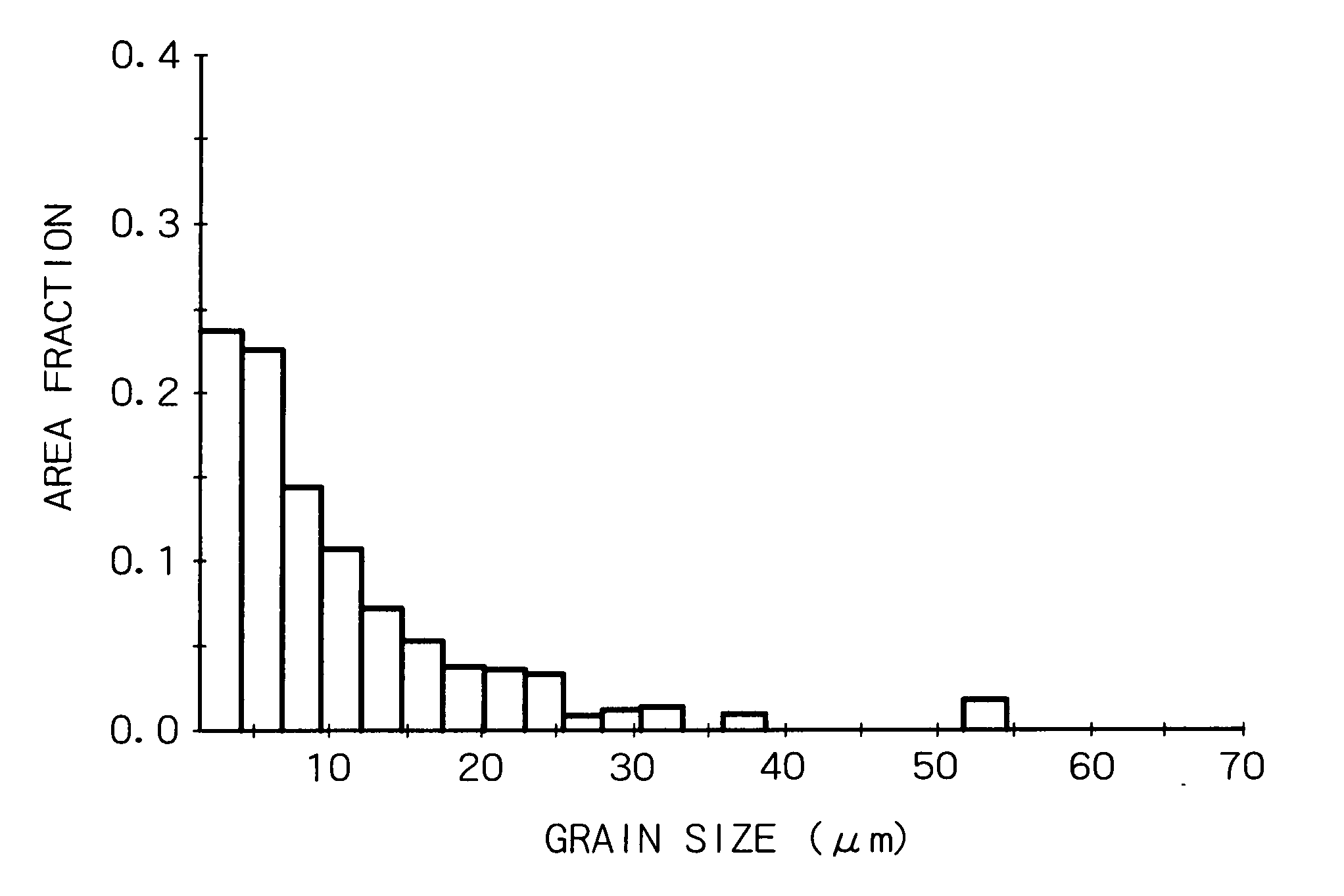

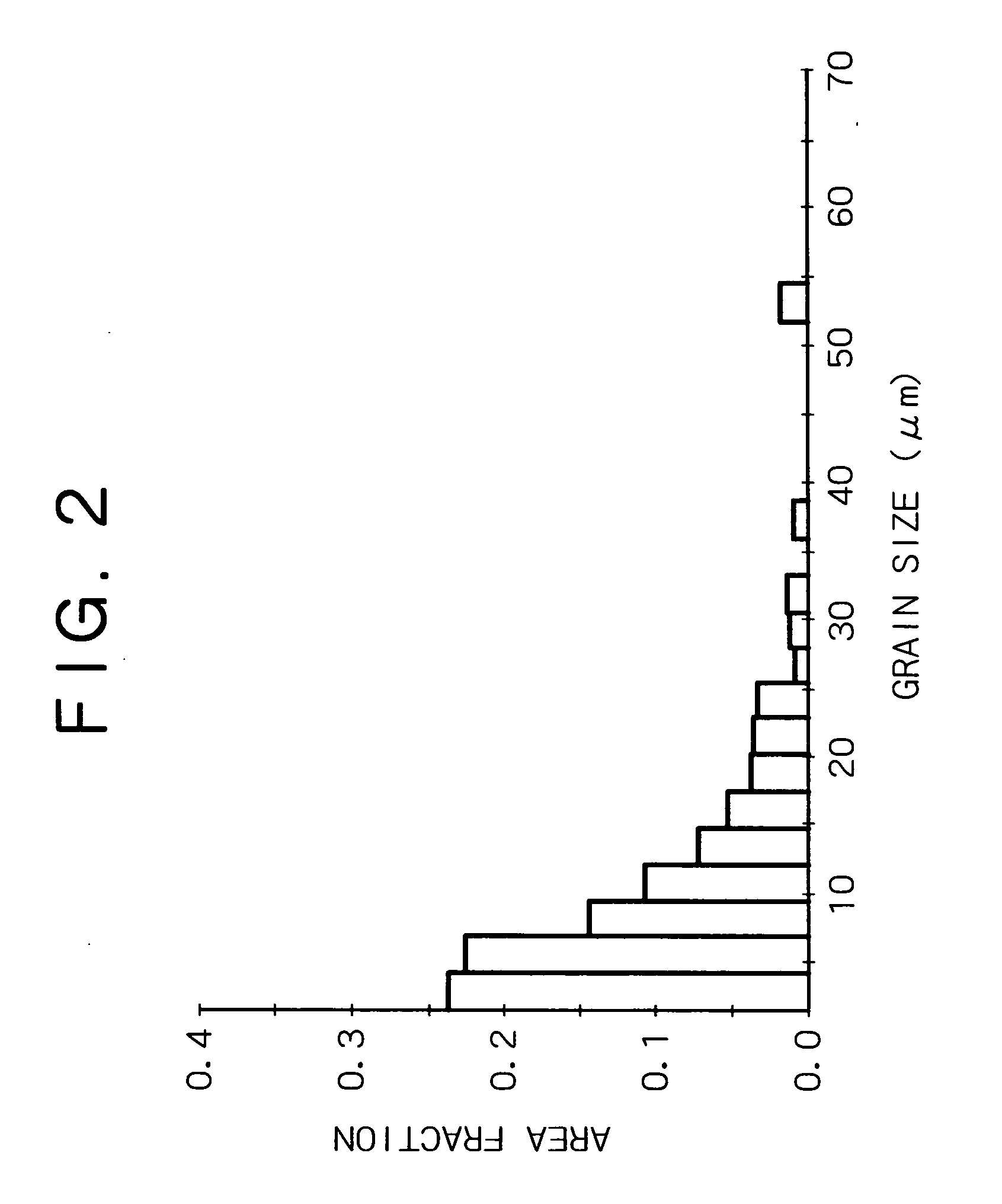

[0037] The copper alloy sheets were annealed at 500° C. fore 1 min in a salt bath. Specimens were sampled from the annealed copper alloy sheets. The specimens were ground and buffed. The surfaces of the specimens were finished by electrolytic polishing. A region of 500 μm×500 μm in the surface of each of the tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com