Edging wheel and method for making it

A manufacturing method and a technology of edging wheels, which are applied to machine tools, grinders, and abrasives suitable for grinding the edge of workpieces, can solve problems such as high cost, complex structure, and unsatisfactory users, and achieve low manufacturing cost and high processing quality. Good, the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

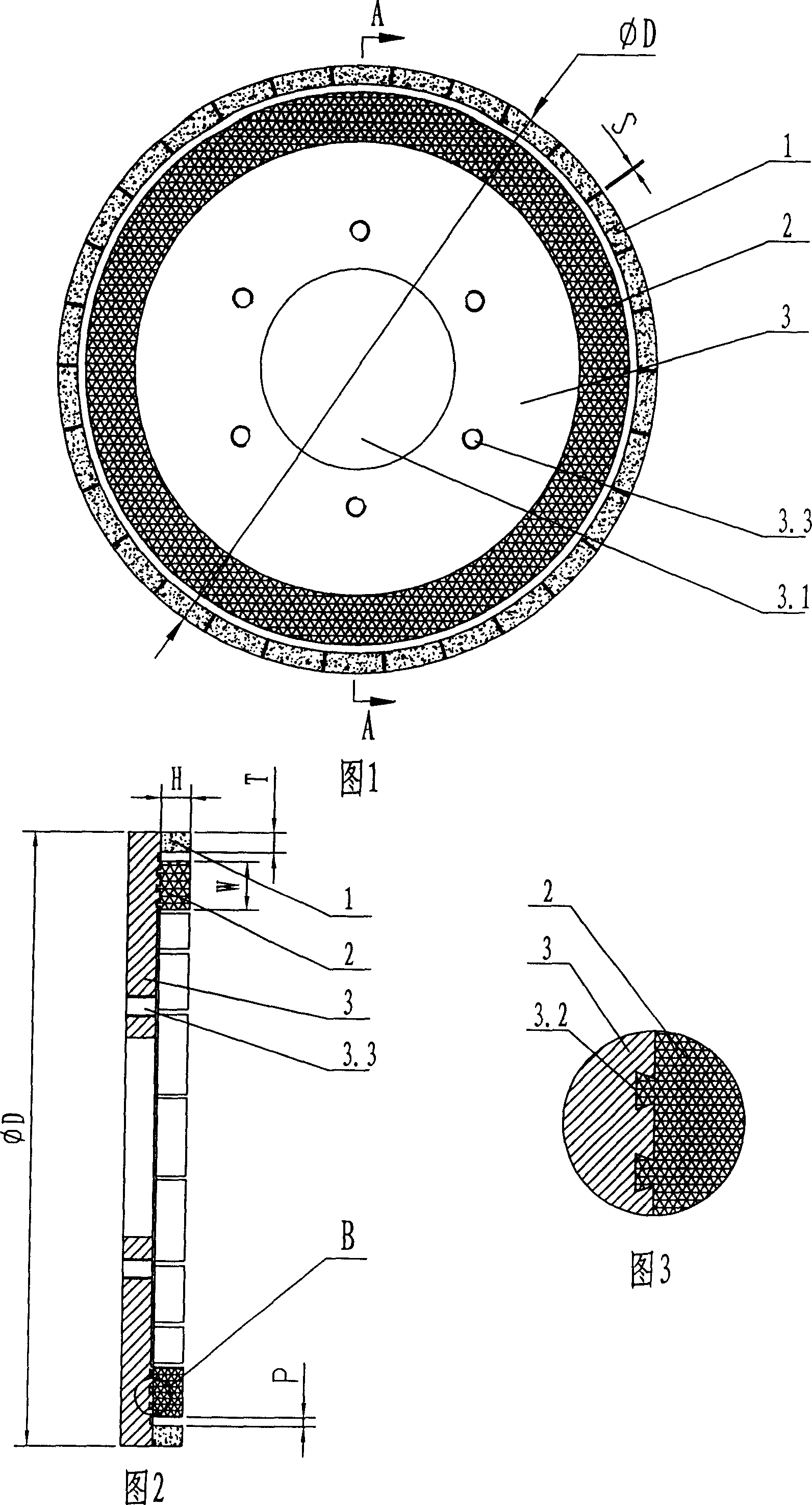

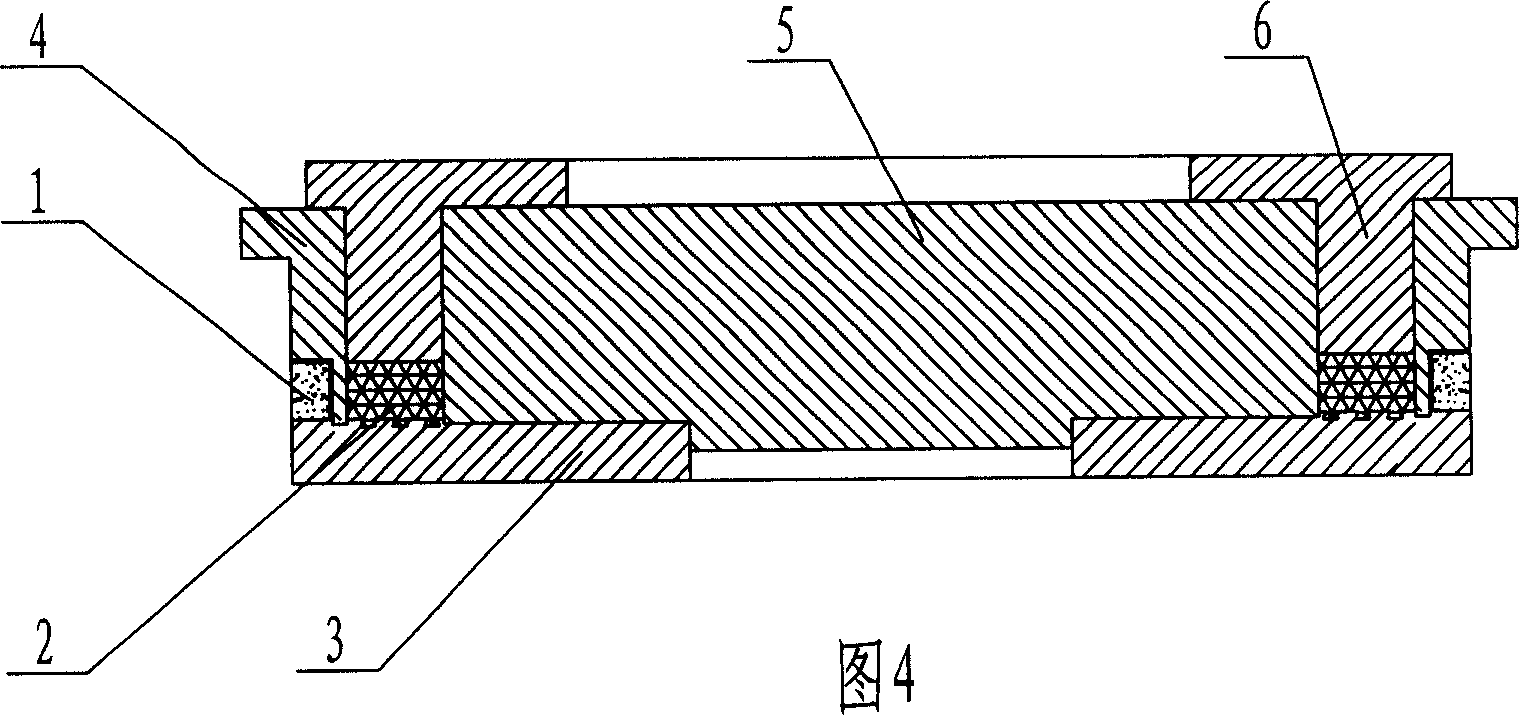

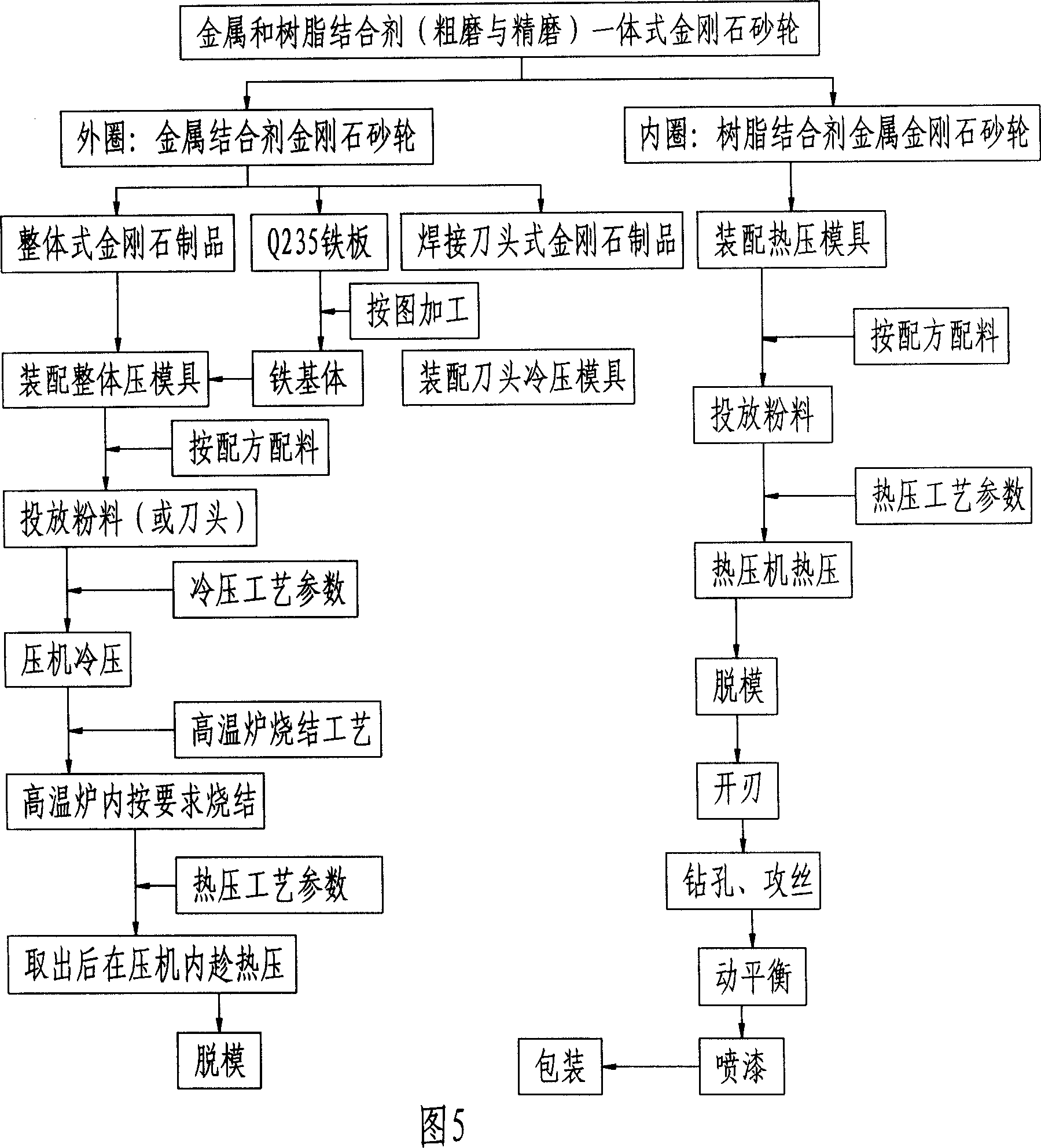

[0024] Referring to Fig. 1-Fig. 3, the edging wheel includes a grinding wheel arranged on the mounting base plate 3, the grinding wheel has two inner and outer layers, the inner layer grinding wheel 2 made of resin bonded diamond and the outer layer grinding wheel 1 made of metal bonded diamond are concentric layout. The inner grinding wheels 2 are continuously arranged in a ring shape, and the outer grinding wheels 1 are arranged in a ring shape continuously or evenly and intermittently. The structure of the continuous arrangement is shown in the figure. The cross sections of the inner grinding wheel 2 and the outer grinding wheel 1 are trapezoidal or rectangular or square. The figure shows a rectangular structure, and there is a gap between the inner grinding wheel 2 and the outer grinding wheel 1 . The mounting base plate 3 is provided with an annul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Section width | aaaaa | aaaaa |

| Section width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com