Diamond grinding material sequential distributing system and process

A diamond and abrasive technology, which is applied in the field of diamond abrasive orderly arrangement system and arrangement technology, can solve the problems of short research time, high cutting resistance, and inability to ensure uniform distribution of diamond abrasive, achieving high efficiency and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

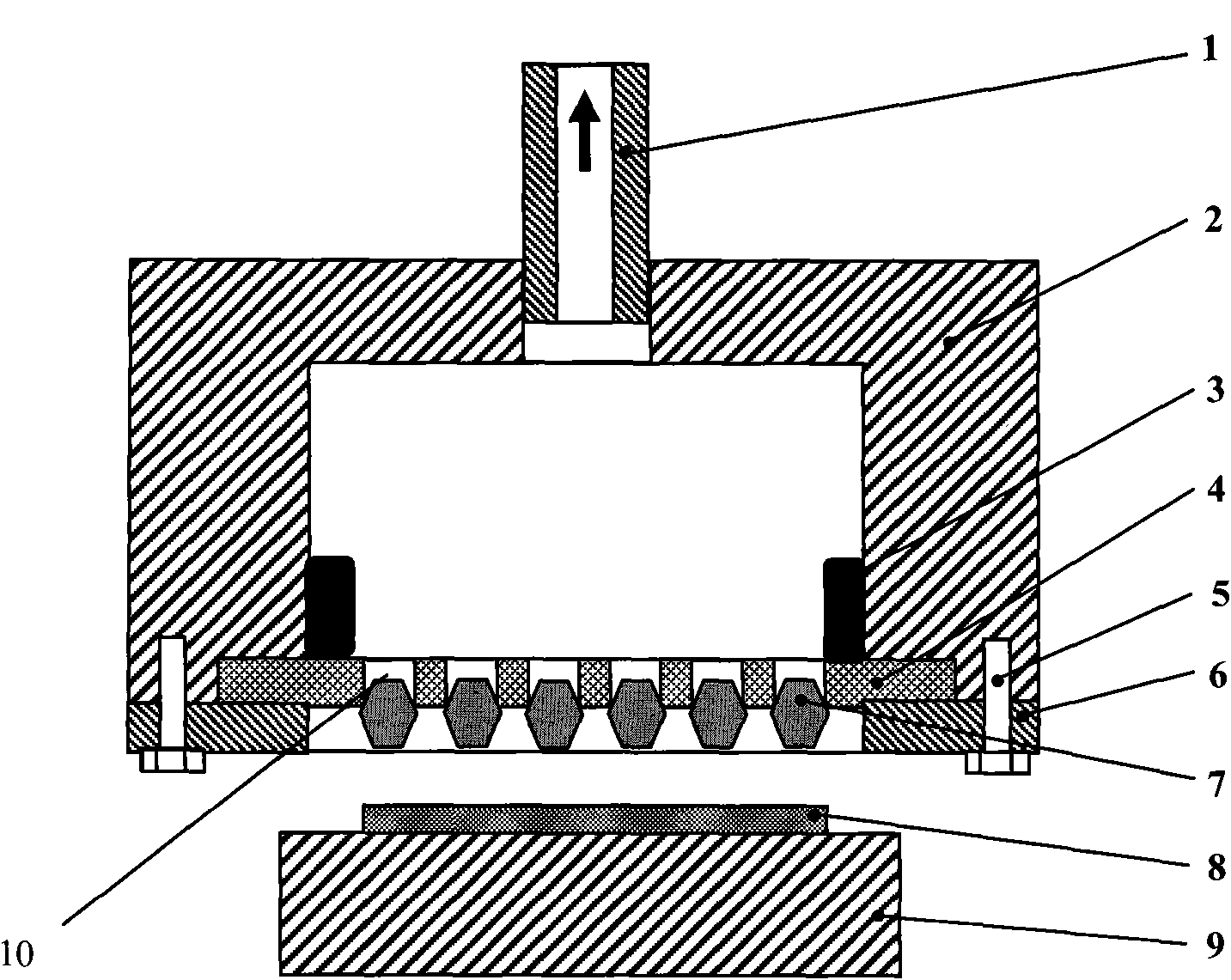

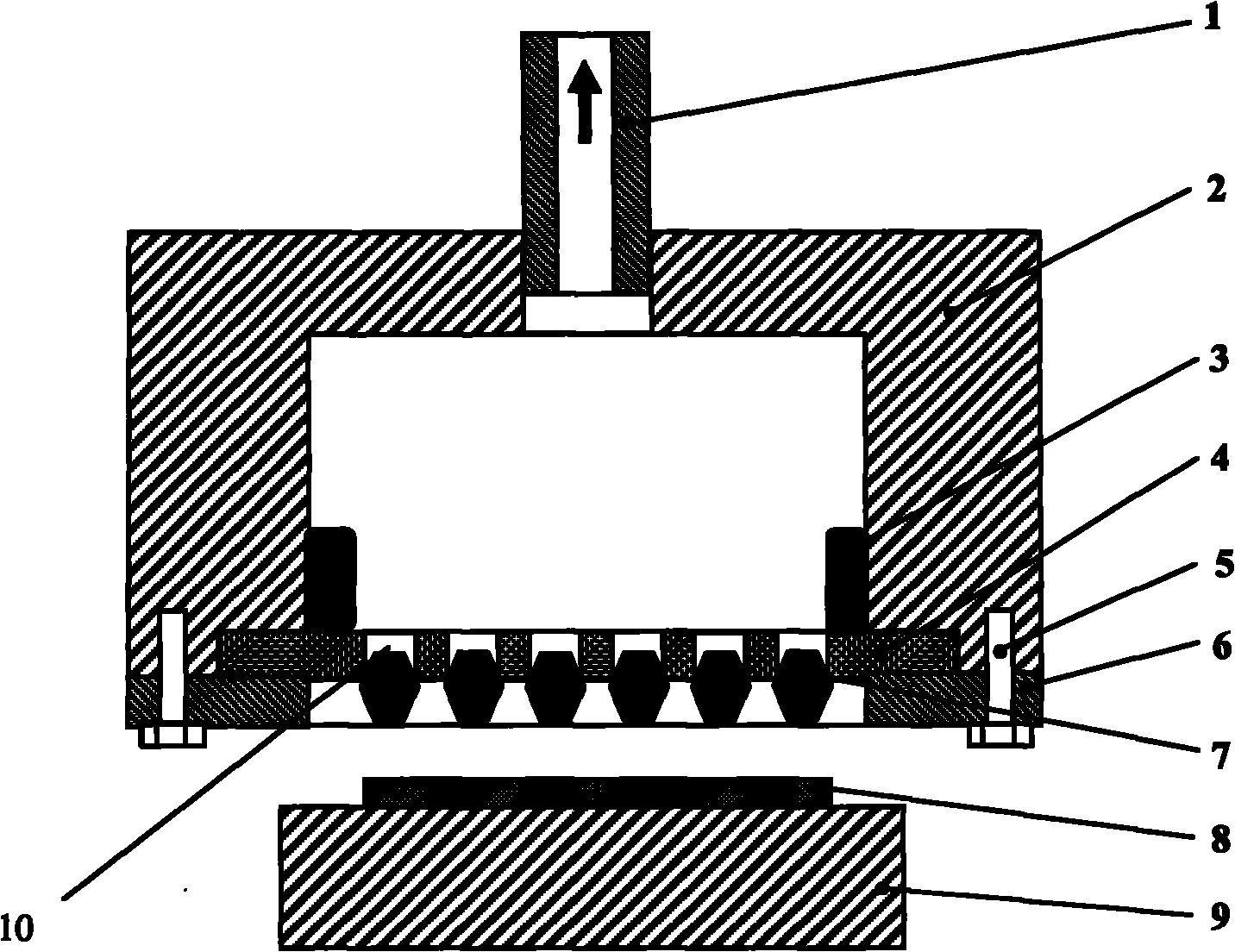

[0028] A new diamond abrasive orderly arrangement system, the system includes a vacuum pumping pipe (1), a vacuum chamber cylinder liner (2), and the lower end surface of the cylinder liner is fixed by screws (5) and pressure plates (6) to fix the orderly arrangement holes of abrasive materials plate (4), 1900 holes (10) are arranged in an orderly manner in the arrangement plate, which can absorb and fix diamond abrasives (7), and a vibrator (3) is fixed above the arrangement plate for vibration and blanking, and the magnetic workbench ( 9) A plurality of cold-pressed thin blanks (8) coated with glue on the surface can be adsorbed and fixed. Wherein, the diameter of the hole (10) on the abrasive arrangement plate (4) is 1 / 3 of the diameter of the diamond abrasive (7).

[0029] The orderly arrangement process of diamond abrasives includes the following steps:

[0030] ①Cold-press the matrix metal powder into a thin billet with a thickness of 0.2mm;

[0031] ②Arrange a plurali...

Embodiment 2

[0037] A new diamond abrasive orderly arrangement system, the system includes a vacuum pumping pipe (1), a vacuum chamber cylinder liner (2), and the lower end surface of the cylinder liner is fixed by screws (5) and pressure plates (6) to fix the orderly arrangement holes of abrasive materials plate (4), 2,500 holes (10) are arranged in an orderly manner in the arrangement plate, which can absorb and fix diamond abrasives (7), and a vibrator (3) is fixed above the arrangement plate for vibration blanking, and the magnetic workbench ( 9) A plurality of cold-pressed thin blanks (8) coated with glue on the surface can be adsorbed and fixed. Wherein, the diameter of the hole (10) on the abrasive arrangement plate (4) is 1 / 3 of the diameter of the diamond abrasive (7).

[0038] The orderly arrangement process of diamond abrasives includes the following steps:

[0039] ①Cold-press the matrix metal powder into a thin billet with a thickness of 1.5mm;

[0040] ②Arrange a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com