High-precision non-water-based nano-diamond grinding fluid and preparation method and application thereof

A diamond and nano-level technology, applied in the field of high-precision grinding and polishing, can solve problems such as hydrolysis, deliquescence, and difficult polishing efficiency that cannot be completely eliminated, and achieve the effect of improving polishing efficiency and polishing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

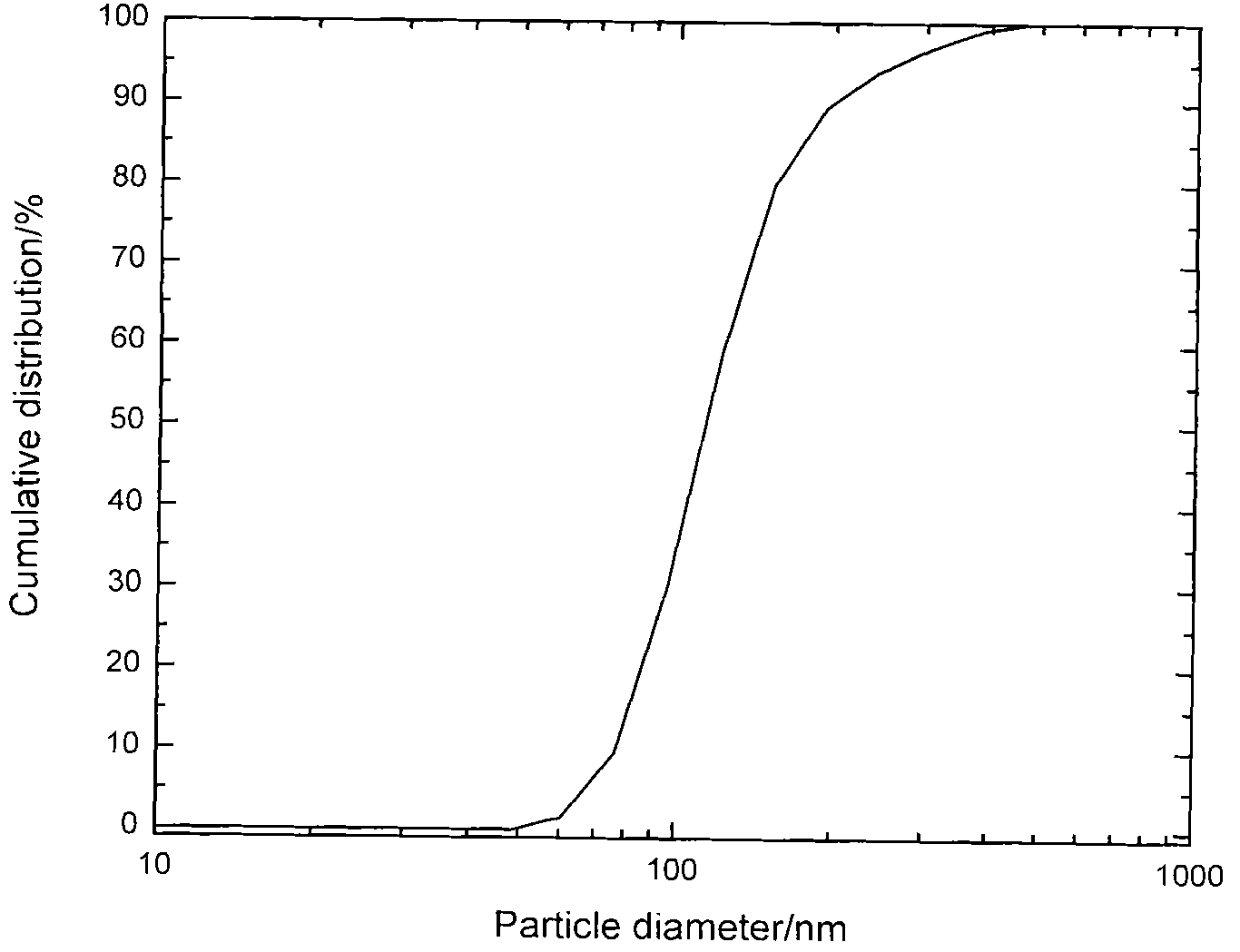

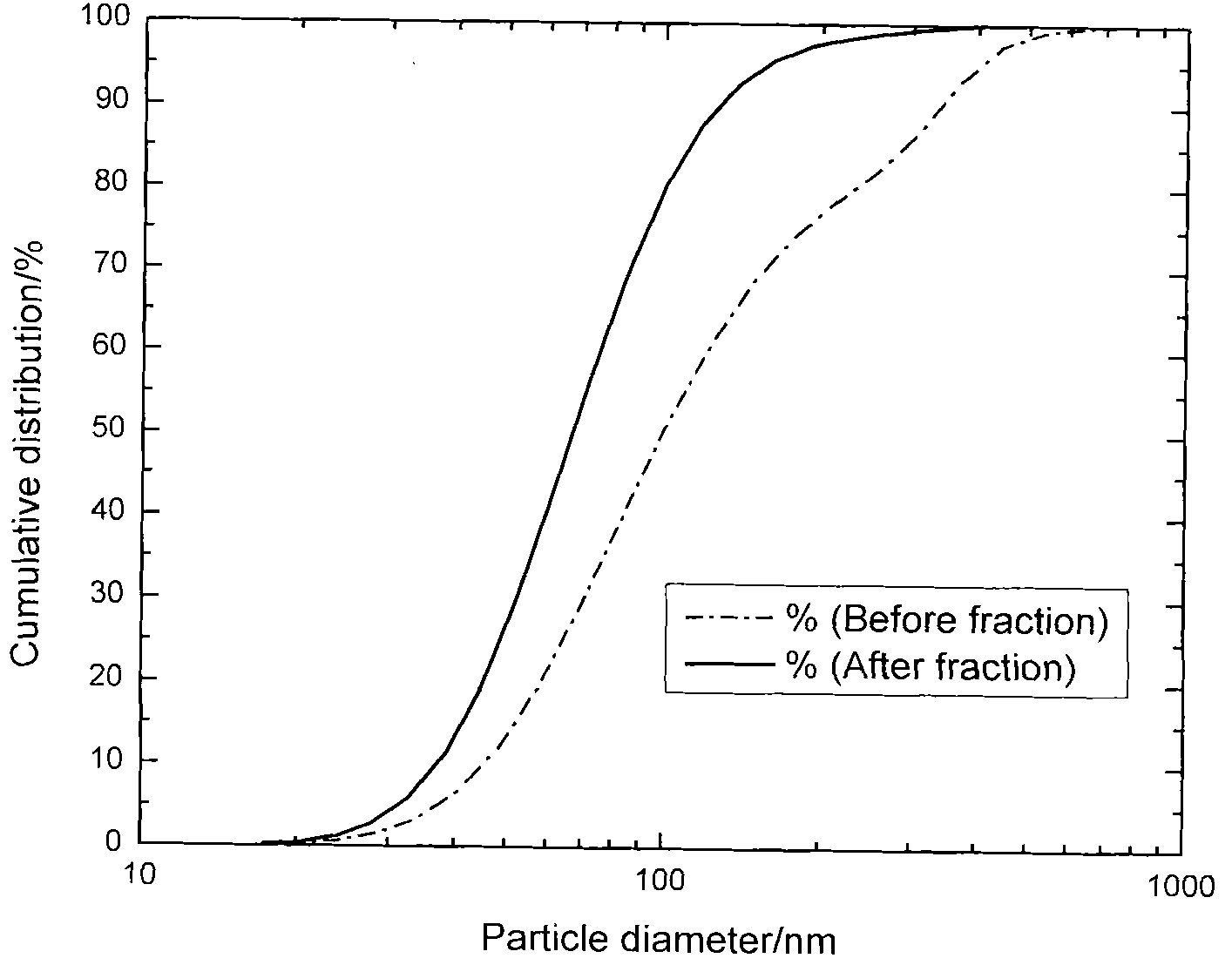

[0036] Adjust the pressure of the airflow crushing equipment to 1.2Mpa, and fully refine the blast-dried synthetic diamond raw materials until 60% of the diamond particle size is less than 200nm, then transfer it to a fluidized bed reactor, pass hydrogen, and heat-treat at a high temperature of 500°C for 8 hours. The gas flow rate is 120L / h. After completion, pour the diamond into the beaker, add nitric acid in a ratio of 1:1, supplement deionized water to keep the concentration of nitric acid in the solution greater than 1mol / L, heat the reaction until boiling, assist stirring, and keep boiling for 1 hour , after centrifugation, pour the diamond into the beaker, add potassium hydroxide in a ratio of 1:1, heat the reaction, assist stirring, and then overflow and elutriate, and then add the mixed solution of deionized water and glycerol / deionized water respectively (volume ratio is 1:5) in the hydrocyclone to separate and remove coarse particles with a particle size larger than ...

Embodiment 2

[0038] Use ball milling to fully refine the explosive-dried synthetic diamond raw material until 60% of the diamond particle size is less than 200nm, then transfer it to a fluidized bed reactor, pass hydrogen, and heat-treat at 500°C for 8 hours at a high temperature cycle, with an air flow rate of 120L / h. After completion, pour the diamond into the beaker, add hydrochloric acid in a ratio of 1:2, add deionized water to keep the concentration of hydrochloric acid in the solution greater than 1mol / L, heat the reaction to boiling, assist stirring, keep boiling for 1 hour, and pour the diamond into the beaker after centrifugation Put it into a beaker, add potassium hydroxide in a ratio of 1:1, heat the reaction, assist stirring, and then overflow and elutriate, and then add the mixed solution of deionized water and ethylene glycol / deionized water (volume ratio is 1:3 ) in a hydrocyclone to separate and remove coarse particles with a particle size larger than 200nm and fine particl...

Embodiment 3

[0040] Adjust the pressure of the airflow crushing equipment to 1.2Mpa, fully refine the blast-dried synthetic diamond raw material until 60% of the diamond particle size is less than 200nm, then transfer it to a shaping ball mill, and shape it for 8 hours, and then pour the diamond into a beaker. Add nitric acid in a ratio of 1:2, add deionized water to keep the concentration of nitric acid in the solution greater than 1mol / L, heat the reaction until boiling, assist stirring, keep boiling for 1 hour, and pour the diamond into the beaker after centrifugation, press 1:1 Potassium hydroxide is added at a certain ratio, heated for reaction, assisted stirring, and then centrifuged, then transferred to deionized water and purified by ion exchange resin, and the purified diamond is chemically analyzed, and the impurity content is only 0.0368%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com