Nano-diamond coating cutting tool and application thereof to mouth rehabilitation ceramic machining

A nano-diamond and cutting tool technology, applied in the field of machining and manufacturing, can solve the problems of ceramic chipping, cutting edge sharpness reduction, ceramic cracking, etc., and achieve the effect of prolonging service life, low friction coefficient and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

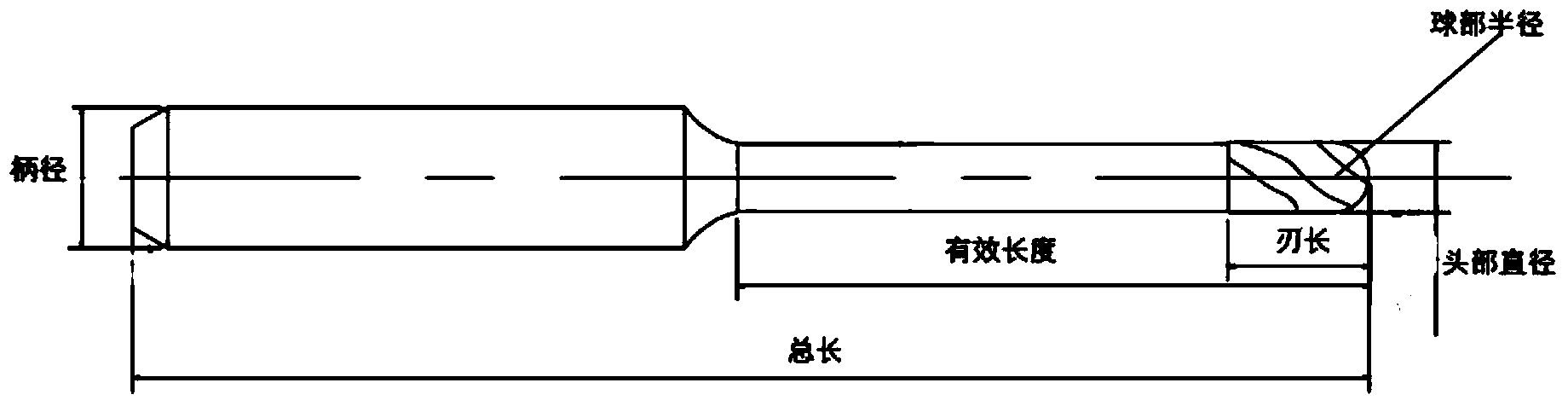

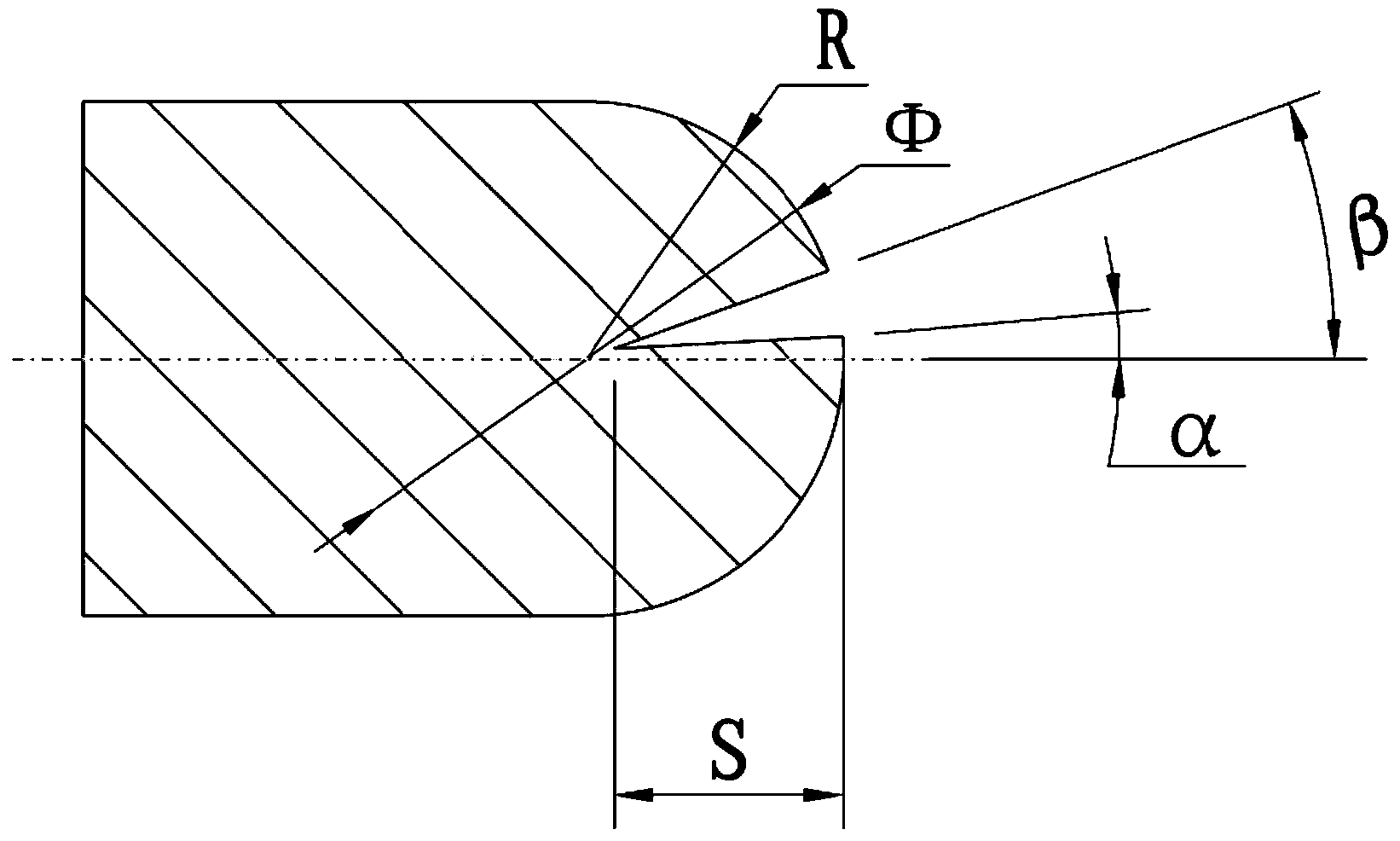

[0018] Embodiment 1 The nano-diamond coating tool provided by the present invention is made

[0019] Step 1: Select the appropriate cemented carbide substrate material

[0020] Since the coating process is carried out at a high temperature above 800°C, the selected base material should be cemented carbide. Before the coating process, selecting the appropriate cemented carbide substrate material for surface treatment has an important impact on the coating effect and the adhesion of the diamond coating. Because in cemented carbide materials, Co is an important binder of cemented carbide powder, and Co can enhance the toughness of materials, so Co is an important element of cemented carbide matrix materials. However, the presence of Co will have a negative impact on the film formation of diamond, so the content of Co should be controlled within a reasonable range. The mass percentage of Co in the selected cemented carbide base material is controlled within 6%, and the grain siz...

Embodiment 2

[0032] Using the nano-diamond-coated tool provided in Example 1, the tool travel is 1400mm / min and the spindle speed is 25000rpm when processing pre-sintered ceramics for dental restoration, and the service life is increased by 25-30% compared with ordinary diamond-coated tools.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com