Efficient smashing equipment of foamed plastic

A high-efficiency crushing and foaming plastic technology, which is applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of inability to clean blades conveniently and quickly, achieve long service life, not easy to deform, and improve practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

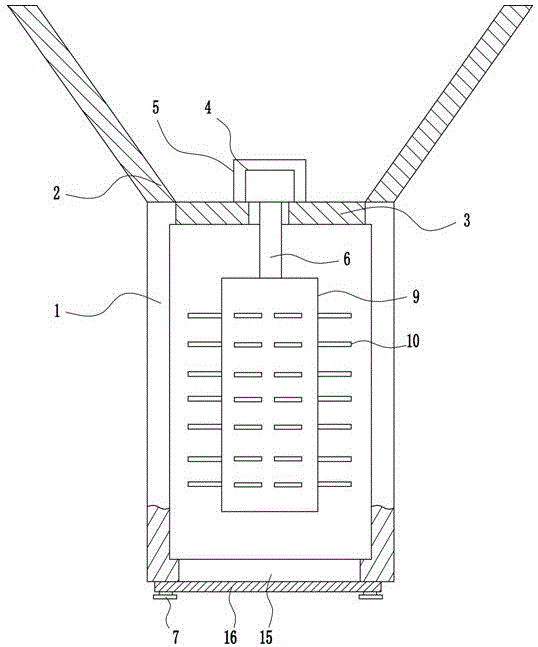

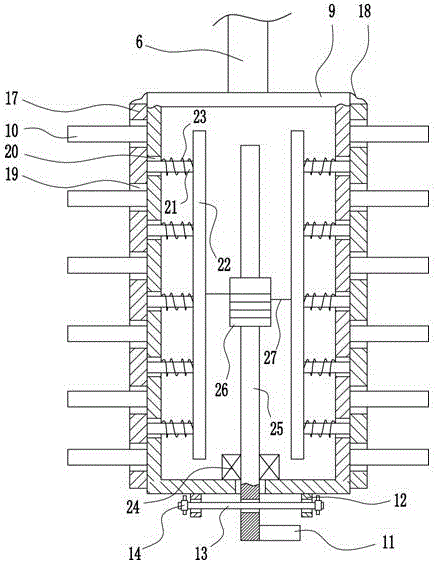

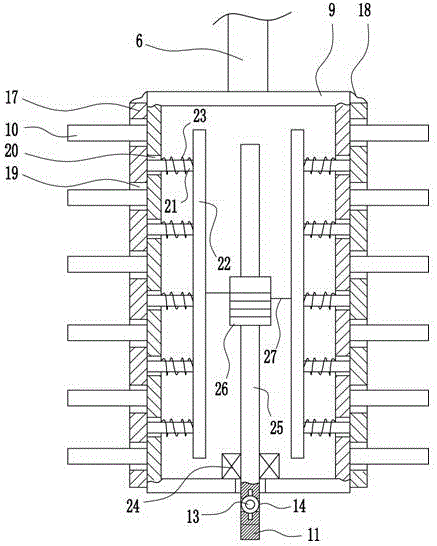

[0029] A foam plastic efficient crushing equipment, such as Figure 1-4 As shown, it includes a crushing box 1, a feeding hopper 2, a blocking rod 3, a rotating motor 4, a first protective cover 5, a first rotating rod 6, a screw 7, a cuboid crushing cylinder 9, a blade 10 and a baffle 16, crushing The top of the box 1 is connected with the feeding hopper 2 by means of bolts, and the upper part of the crushing box 1 is connected with the blocking rod 3 by means of bolts. There is a small hole in the middle of the blocking rod 3, and the middle of the top of the blocking rod 3 is connected by bolts. A first protective cover 5 is connected, and a rotating motor 4 is connected in the first protective cover 5 by means of bolt connection. Through the small hole in the middle of the blocking rod 3, the lower end of the first rotating rod 6 is welded with a cuboid crushing cylinder 9, the four sides of the cuboid crushing cylinder 9 are uniformly welded with blades 10, and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com