Rubber and plastic granulator

A technology of granulator and plastic, which is applied in the direction of metal processing, etc., and can solve problems such as defects in processed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

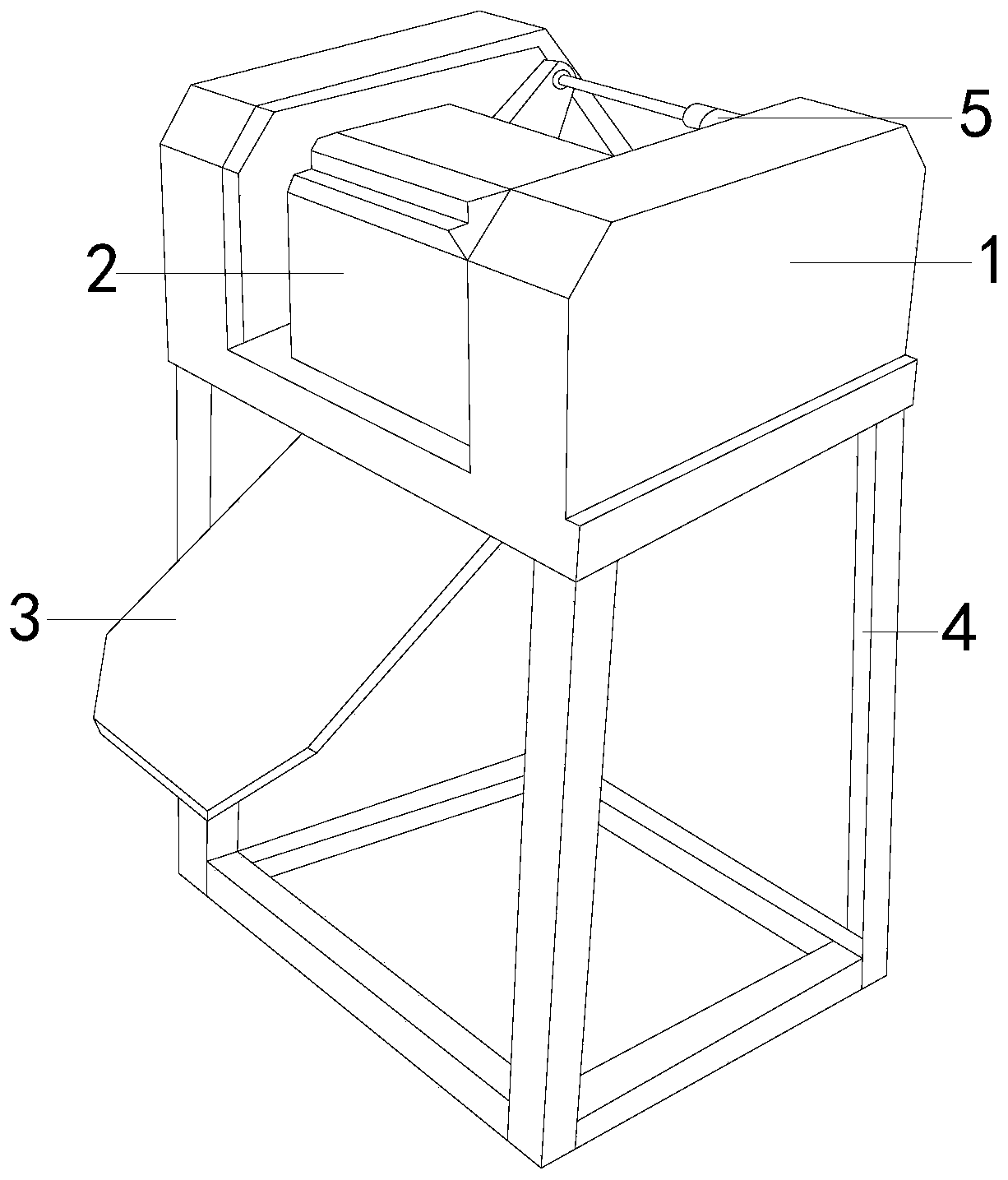

[0024] see figure 1 , the present invention provides a kind of rubber plastic granulator, its structure comprises: Drive case 1, granulation mechanism 2, feeding plate 3, frame 4, described drive case 1 side connects granulation mechanism 2, granulation mechanism 2 The bottom position is provided with a feeding plate 3 and communicates with it. The frame 4 is arranged on the bottom end surface of the drive case 1. The drive case 1 is the main structure of the upper part of the equipment. The conveying plate 3 is mainly used to convey the rubber and plastic particles that have been granulated. It has a certain arc-shaped structure as a whole, which can accelerate the rubber and plastic particles and prevent the vibration caused by excessive vibration on the smooth surface during the sliding process. The particles are ejected from the feeding plate 3, so that the feeding plate 3 has a certain particle gathering effect, and the frame 4 is the frame structure of the lower part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com