Intelligent crushing treatment equipment for household garbage

A technology for domestic waste and processing equipment, which is applied in grain processing, chemical instruments and methods, and solid waste removal. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

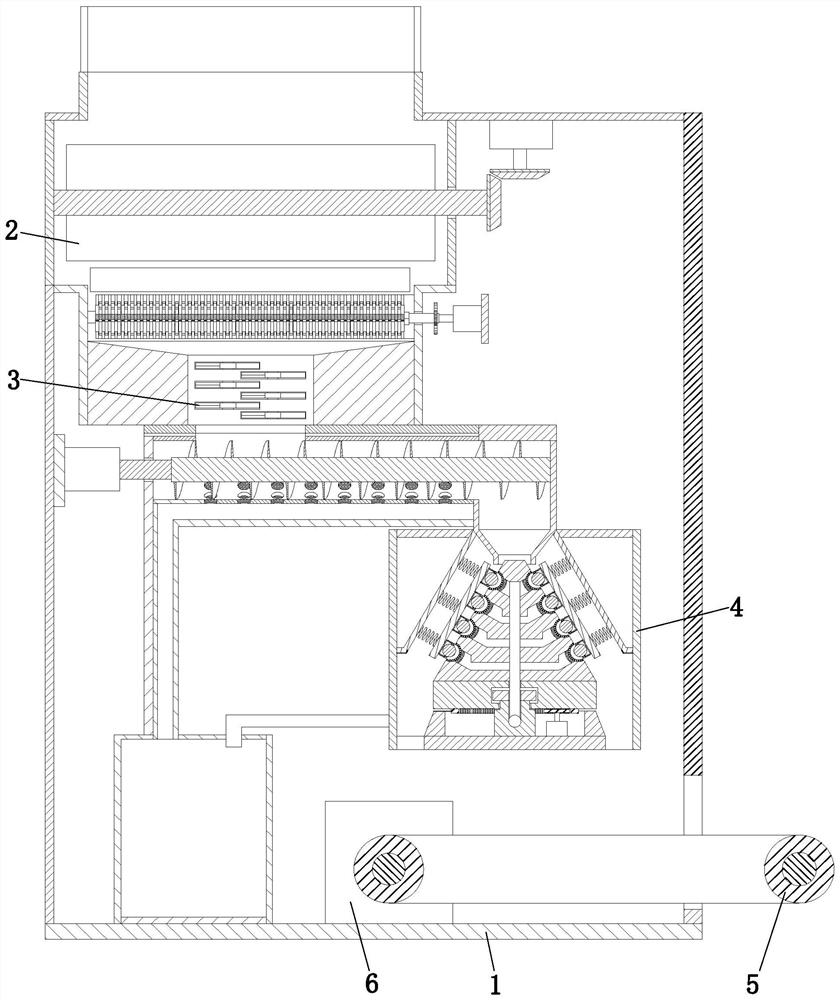

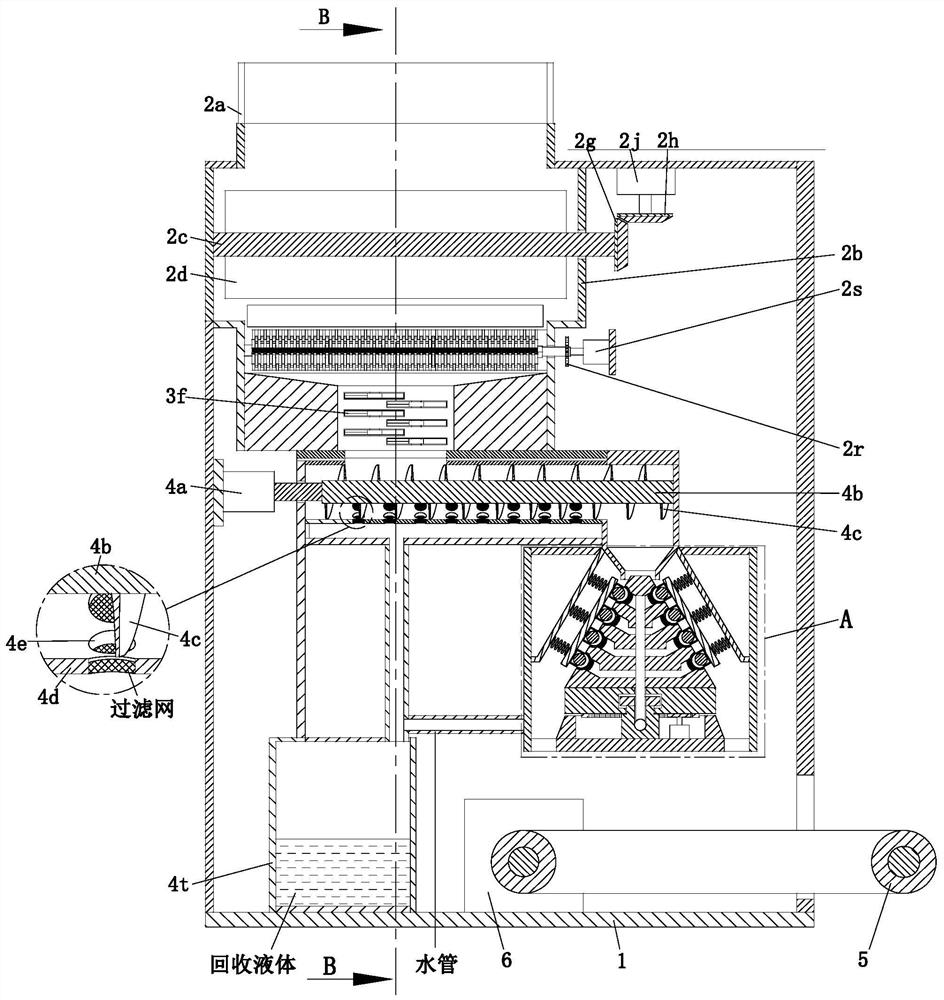

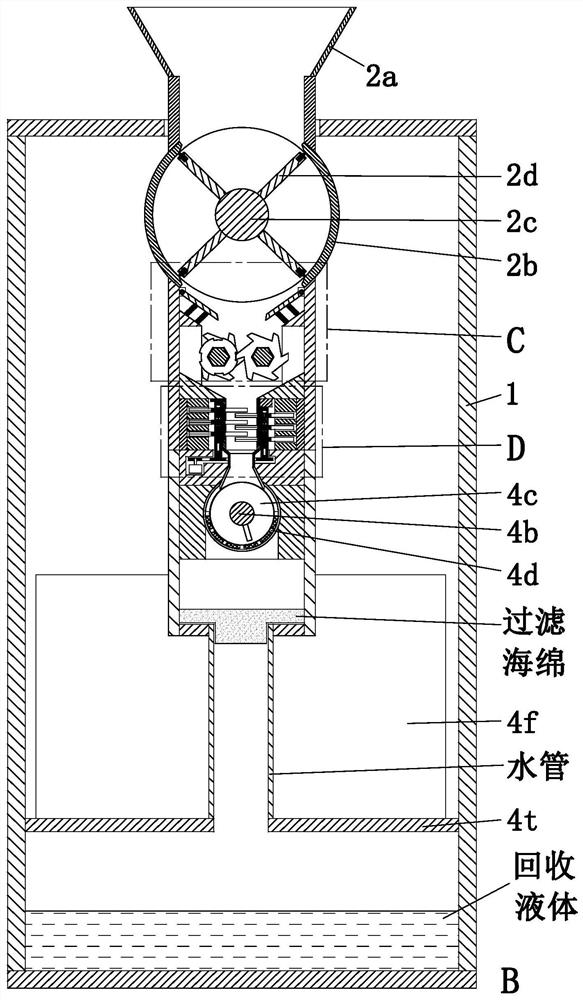

[0025] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0026] An intelligent pulverization processing equipment for domestic waste, comprising a crushing box 1, a feeding mechanism 2, a crushing mechanism 3, a sewage collection mechanism 4, a material return conveyor belt 5 and a material return motor 6, and the upper end of the crushing box 1 is installed with The conveying mechanism 2 is located below the conveying mechanism 2 and is equipped with a crushing mechanism 3 through rotation and fit, and a sewage collection mechanism 4 is installed under the crushing mechanism 3, and a material return is installed in the crushing box 1 below the sewage collection mechanism 4 through rotation and fit. The conveyor belt 5 is equipped with a material return motor 6 through a motor base in the crushing box 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com