Method for machining rotor of screw compressor through formation CBN grinding wheel

A technology of a screw compressor and a processing method, which is applied to metal processing equipment, manufacturing tools, grinding devices, etc., can solve problems such as difficult promotion of the screw rolling method, complex profiles, and difficulties in the design and manufacture of hobs, achieving convenience and high efficiency Conversion, firm grip, huge time and costly savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for processing a screw compressor rotor forming a CBN grinding wheel, comprising the following steps:

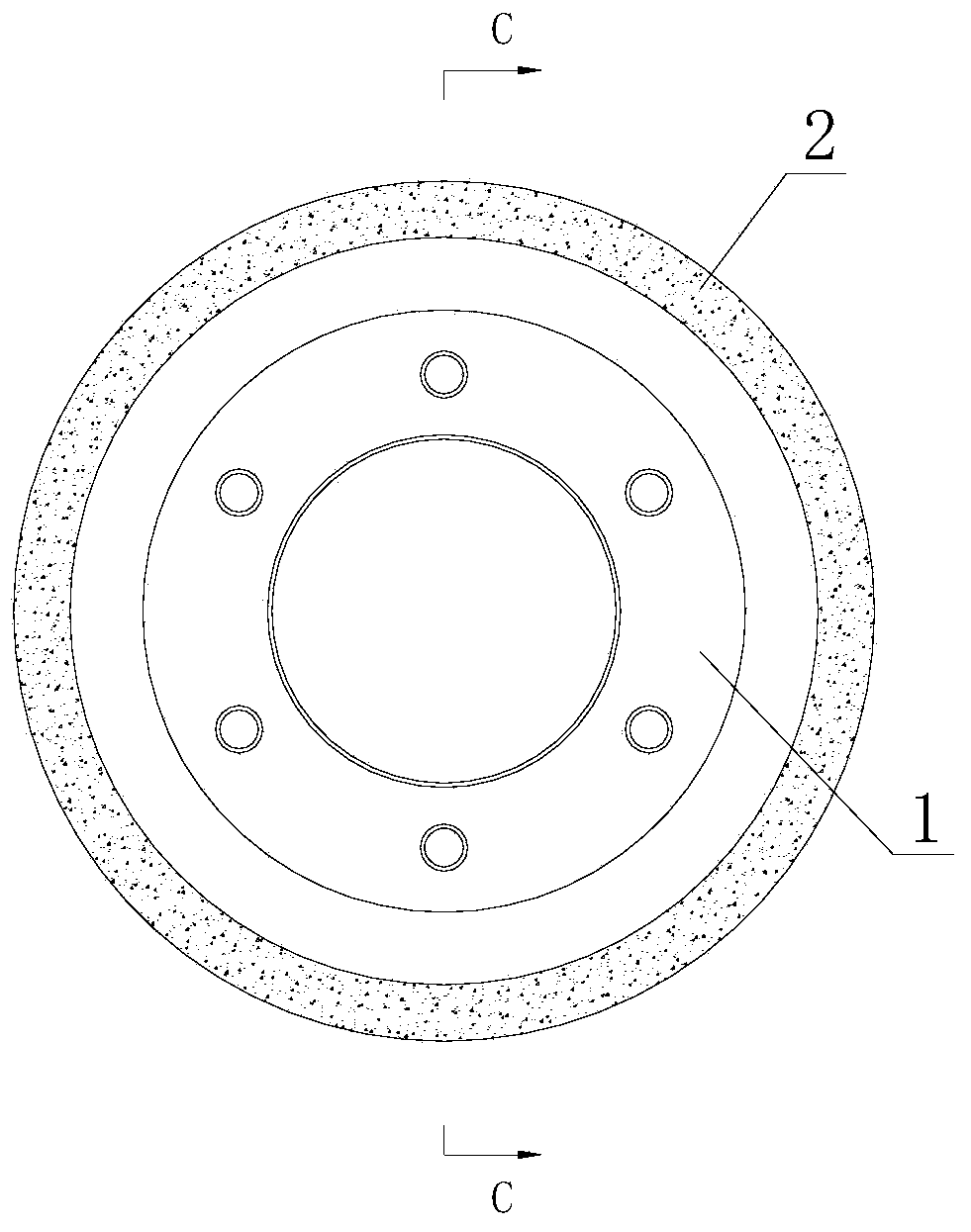

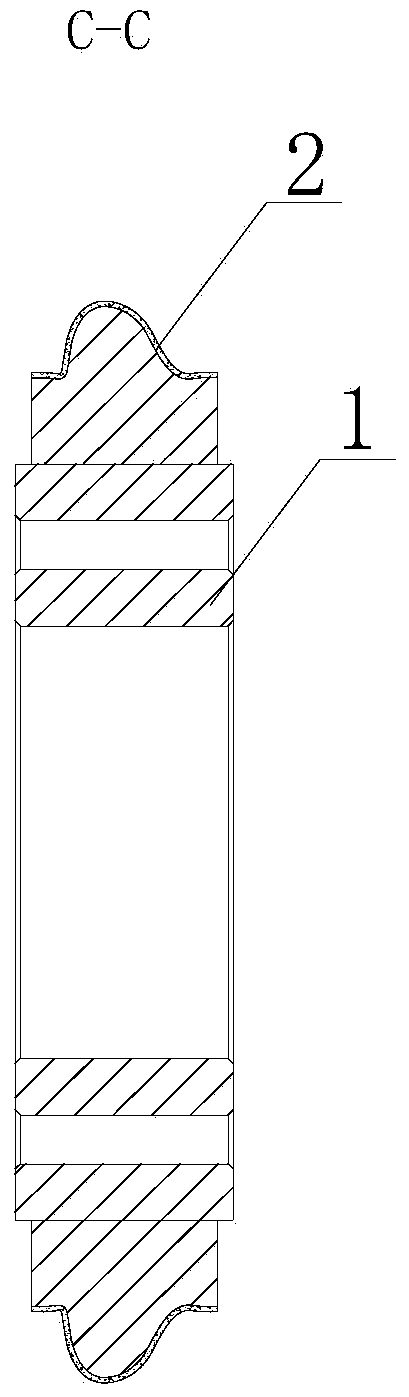

[0034] a. Grinding wheel substrate preparation: Grinding wheel substrate 1 is made of 45 steel forging, the quenched and tempered hardness is HRC28-32, after aging treatment, flaw detection is performed to ensure that there are no defects such as cracks and trachoma;

[0035] b. Semi-finishing of the grinding wheel base: After the semi-finishing of the forging part, according to the actual production situation, through holes are uniformly processed on both ends of the forging, and the two ends and inner holes are processed by the grinder. , the roughness Ra value is ≤0.8μm, the roundness requirement of the inner hole is ≤0.001mm, and the roughness Ra value is ≤0.4μm;

[0036] c. Finishing of the grinding wheel base: fasten the ground grinding wheel base 1 on the fixture of the high-precision CNC lathe, verify that the hole runout is ≤0.0015mm, and the end fac...

Embodiment 2

[0041] A method for processing a screw compressor rotor forming a CBN grinding wheel, comprising the following steps:

[0042] a. Grinding wheel base preparation: Grinding wheel base 1 is forged with 40Cr, the quenched and tempered hardness is HRC28-32, after aging treatment, flaw detection is performed to ensure that there are no defects such as cracks and trachoma;

[0043] b. Semi-finishing of the grinding wheel base: After the semi-finishing of the forging part, according to the actual production situation, through holes are uniformly processed on both ends of the forging, and the two ends and inner holes are processed by the grinder. , the roughness Ra value is ≤0.8μm, the roundness requirement of the inner hole is ≤0.001mm, and the roughness Ra value is ≤0.4μm;

[0044] c. Finishing of the grinding wheel base: fasten the ground grinding wheel base 1 on the fixture of the high-precision CNC lathe, verify that the hole runout is ≤0.0015mm, and the end face runout is ≤0.002...

Embodiment 3

[0049] A method for processing a screw compressor rotor forming a CBN grinding wheel, comprising the following steps:

[0050] a. Grinding wheel base preparation: Grinding wheel base 1 is forged with 35CrMo, the quenched and tempered hardness is HRC28-32, after aging treatment, flaw detection is performed to ensure that there are no defects such as cracks and trachoma;

[0051] b. Semi-finishing of the grinding wheel base: After the semi-finishing of the forging part, according to the actual production situation, through holes are uniformly processed on both ends of the forging, and the two ends and inner holes are processed by the grinding machine. , the roughness Ra value is ≤0.8μm, the roundness requirement of the inner hole is ≤0.001mm, and the roughness Ra value is ≤0.4μm;

[0052] c. Finishing of the grinding wheel base: fasten the ground grinding wheel base 1 on the fixture of the high-precision CNC lathe, verify that the runout of the hole is ≤0.0015mm, and the runout ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roundness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com