A kind of nanocrystalline alloy and preparation method thereof

A nanocrystalline alloy, a fast technology, used in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of insensitivity to service temperature and low loss, and achieve stable performance, safety and reliability, low high frequency loss, and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

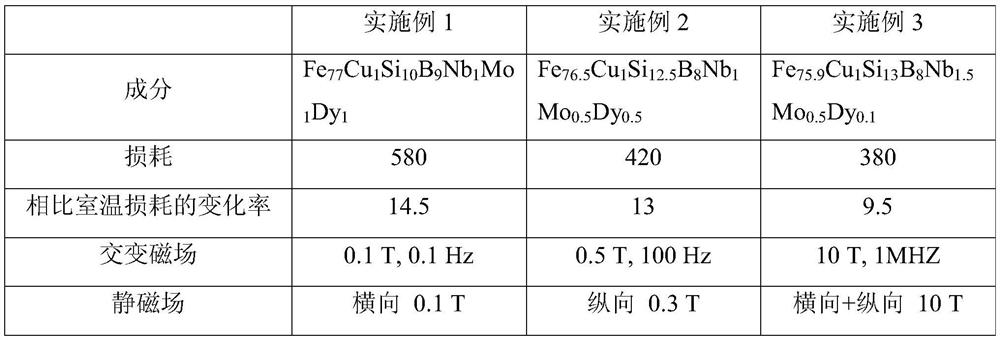

Embodiment 1

[0046] (1) Obtain Fe by smelting 77 Cu 1 Si 10 B 9 Nb 1 Mo 1 Dy 1 Alloy strip, the alloy strip is placed in a heat treatment furnace;

[0047] (2) Slowly raise the temperature to 350°C at a heating rate of 0.01°C / min under the amplitude of the alternating magnetic field of 0.1T and the frequency of 0.1Hz; remove the alternating magnetic field and keep it warm for 0.1min;

[0048] (3) Rapidly raise the temperature to 480°C at a heating rate of 300°C / min, and hold for 1s;

[0049] (4) Increase the transverse static magnetic field with an amplitude of 0.1T, rapidly cool down to 380°C at a rate of 300°C / min, and keep warm for 1s;

[0050] (5) Under the transverse static magnetic field, slowly drop to 260°C at a rate of 0.01°C / min and hold for 0.1min, then quickly drop to room temperature at 300°C / min to obtain a nanocrystalline alloy.

Embodiment 2

[0052] (1) Obtain Fe by smelting 76.5 Cu 1 Si 12.5 B 8 Nb 1 Mo 0.5 Dy 0.5 Alloy strip, the alloy strip is placed in a heat treatment furnace;

[0053] (2) Under the amplitude of the alternating magnetic field of 0.5T and the frequency of 100Hz, the temperature was slowly raised to 400°C at a heating rate of 0.5°C / min; the alternating magnetic field was removed and kept for 10h;

[0054] (3) Rapidly raise the temperature to 590°C at a heating rate of 800°C / min, and hold for 30 minutes;

[0055] (4) Increase the longitudinal static magnetic field with an amplitude of 0.3T, rapidly cool down to 400°C at a rate of 800°C / min, and keep warm for 60 minutes;

[0056] (5) Slowly drop to 320°C at a rate of 1°C / min and keep warm for 100 minutes, then quickly drop to room temperature at 800°C / min to obtain a nanocrystalline alloy.

Embodiment 3

[0058] (1) Obtain Fe by smelting 75.9 Cu 1 Si 13 B 8 Nb 1.5 Mo 0.5 Dy 0.1 Alloy strip, the alloy strip is placed in a heat treatment furnace;

[0059] (2) Slowly raise the temperature to 430°C at a heating rate of 3°C / min at an alternating magnetic field amplitude of 10T and a frequency of 1MHz; remove the alternating magnetic field and keep it warm for 120h;

[0060] (3) Rapidly raise the temperature to 620°C at a heating rate of 1000°C / min, and hold for 60 minutes;

[0061] (4) Increase the transverse and longitudinal static magnetic field with an amplitude of 10T, rapidly cool down to 420°C at a rate of 1000°C / min, and keep warm for 60min;

[0062] (5) Under the transverse and longitudinal static magnetic field, slowly lower the rate of 3°C / min to 340°C for 120h, and then rapidly drop to room temperature at 1000°C / min to obtain a nanocrystalline alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com