Low-saturation narrow-linewidth gyromagnetic material and preparation method thereof

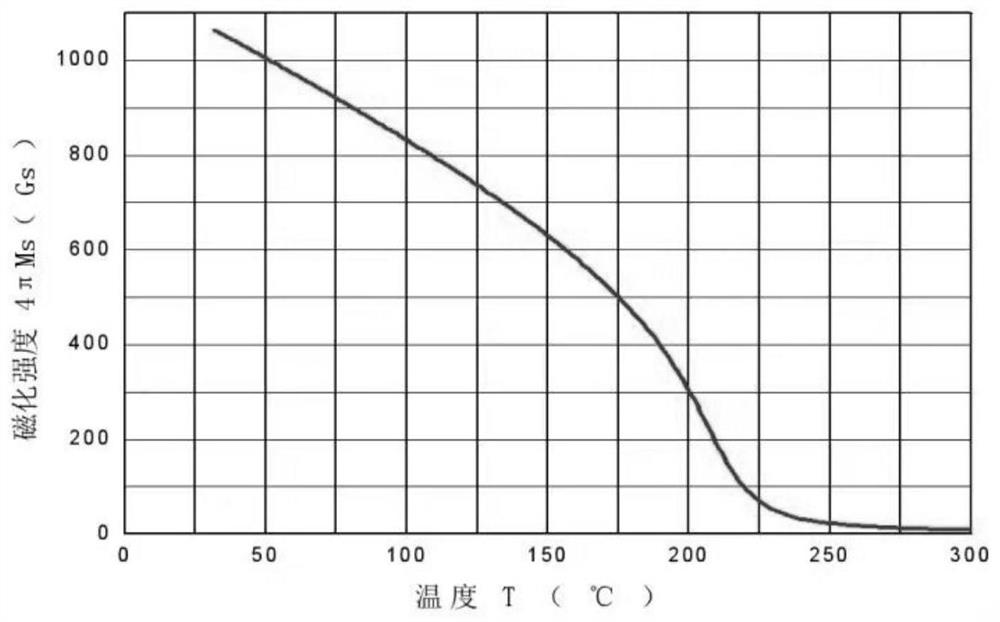

A technology of gyromagnetic material and narrow line width, which is applied in the fields of magnetic materials, inorganic material magnetism, inductance/transformer/magnet manufacturing, etc., can solve the problems of the dielectric constant, line width, and Curie temperature indicators that are not up to standard, etc. Achieving the effect of high dielectric constant at Curie temperature, high performance preparation, and no deterioration of Curie temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

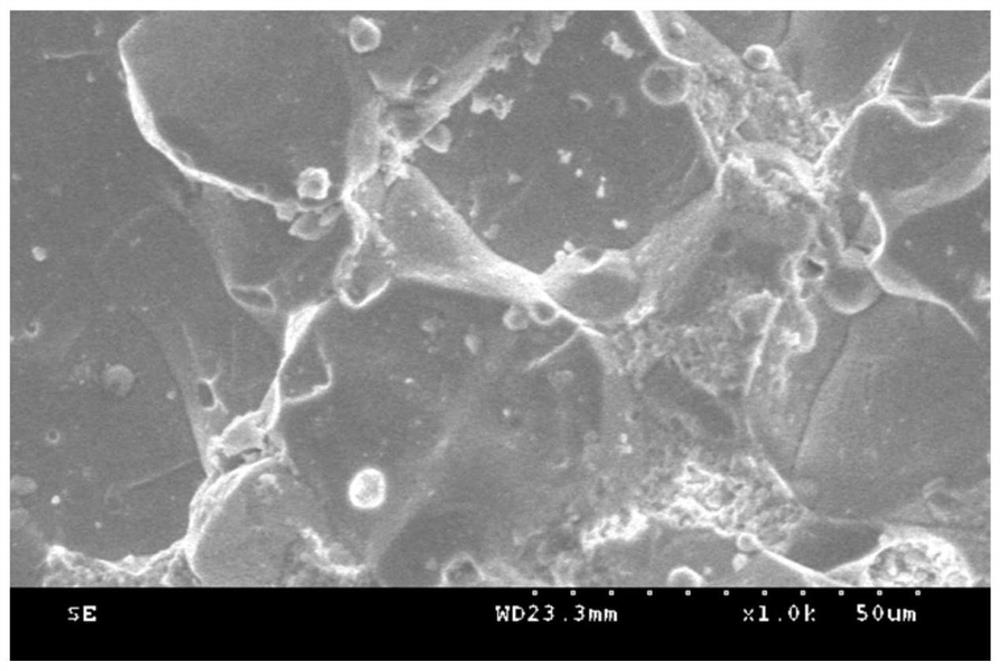

Image

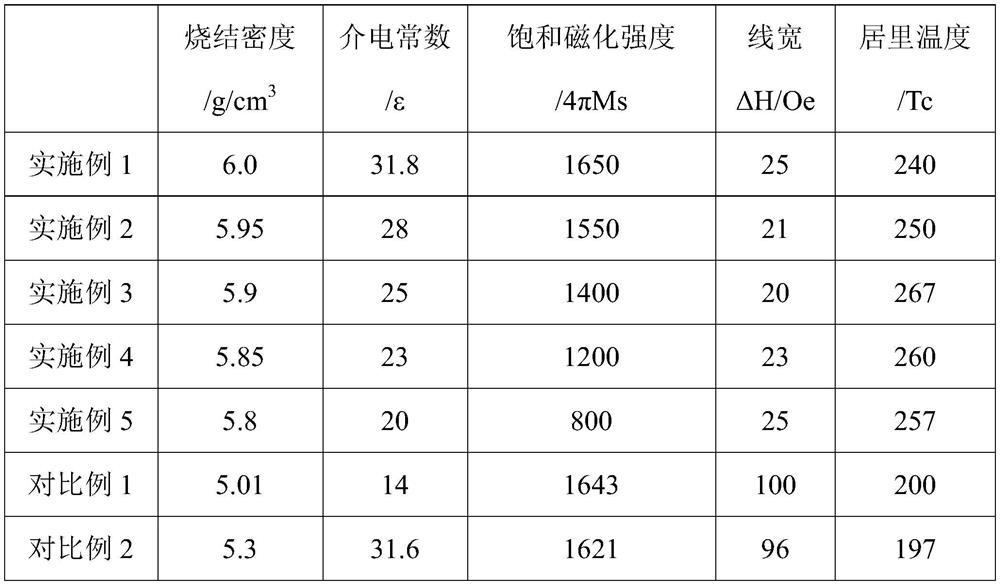

Examples

Embodiment 1

[0081] This embodiment provides a kind of gyromagnetic material and preparation method thereof, the composition of gyromagnetic material is Bi 1.40 Y 0.3 Gd 0.24 Ca 1.06 Fe 3.67 V 0.225 Nb 0.055 Zr 0.5 In 0.5 mn 0.05 o 12

[0082] Prepared as follows:

[0083] ①One-time ball milling: According to the formula, pre-mix all raw materials first, and after mixing evenly, put these raw materials into a stainless steel ball mill tank, and add zirconium balls in a mass ratio of 1:1:1 according to the material, balls and medium and deionized water, add dispersant ammonium citrate (addition is 0.3% of powder quality in the ball mill) and carry out a wet ball mill simultaneously, and the ball mill time is 10h, and the ball mill rotating speed is set as 40r / min, and the ball mill product particle size is controlled as D50 1.57μm, D90 2.34μm; D993.08μm, the ratio of volume to surface area is 0.98μm.

[0084] ②Drying: Dry the slurry obtained from the primary ball milled slurry i...

Embodiment 2

[0093] This embodiment provides a kind of gyromagnetic material and preparation method thereof, the composition of gyromagnetic material is Bi 1.30 Y 0.3 Gd 0.05 Ca 1.35 Fe 4.025 V 0.425 Nb 0.1 Zr 0.15 In 0.15 sn 0.15 o 12

[0094] Prepared as follows:

[0095] ①Primary ball milling: Pre-mix all raw materials according to the formula, and after mixing evenly, put these raw materials into a stainless steel ball mill tank, add powder, balls and medium in a mass ratio of 1:1:1 to zirconium balls and Deionized water, adding dispersant (addition amount is 2% of powder quality in ball milling) carries out wet ball milling once, ball milling time is 10h, and ball mill rotating speed is set as 40r / min, and the particle size of solid particles in ball milling gained material is controlled as : D50 1.57 μm, D90 2.34 μm, D99 3.08 μm, the ratio of volume to surface area is 0.98 μm.

[0096] ②Drying: Dry the slurry from primary ball milling in an oven at 100°C. After the dryin...

Embodiment 3

[0105] This embodiment provides a kind of gyromagnetic material and preparation method thereof, the composition of gyromagnetic material is Bi 1.20 Y 0.2 Gd 0.2 Ca 1. 4 Fe 4 V 0.5 Nb 0.1 Zr 0.2 In 0.15 mn 0.05 o 12 ;

[0106] Prepared as follows:

[0107] ①Primary ball milling: Pre-mix all raw materials according to the formula, and after mixing evenly, put these raw materials into a stainless steel ball mill tank, add powder, balls and medium at a mass ratio of 1:1.2:1.5 into zirconium balls and Deionized water, adding dispersant (addition amount is 3% of powder mass in ball milling) carries out wet ball milling once, ball milling time is 18h, and ball mill rotating speed is set as 60r / min, the particle size control of solid particles in the slurry obtained by ball milling D50 is 0.5 μm, D90 is 1.3 μm, D99 is 1.5 μm, and the ratio of volume to specific surface area is 0.67 μm.

[0108] ②Drying: Dry the slurry from primary ball milling in an oven at 100°C. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com