Low-loss YIG material and preparation method thereof

A low-loss, material-structured technology, applied in the field of electronic ceramic materials, can solve the problems of high dielectric loss, high raw material cost, and large ferromagnetic resonance line width, and achieve the effect of reducing dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment provides a preparation method of low-loss YIG material, comprising the following steps:

[0028] (1) Step 1, the preparation of pre-sintered material:

[0029] (1.1) Using iron oxide, calcium oxide, yttrium oxide and tin oxide as raw materials, according to Y 2.7 Ca 0.3 Fe (4.7-x) Sn 0.3 O 12 , 0≤x≤0.325 ratio to weigh the raw material, and then put it in a nylon tank and use deionized water as a medium for one ball milling for 6-9 hours; preferably, the ball milling time of one ball milling in the step (1.1) is 6h.

[0030] (1.2) After drying and sieving the primary ball abrasive obtained in step 1.1, it is pre-fired at 1200° C. for 4-5 hours, and then cooled to room temperature with the furnace; preferably, the holding time is 4 hours.

[0031] (2) Step 2, secondary ball milling:

[0032] The pre-sintered material obtained in step 1 is placed in a nylon tank, and deionized water is added to carry out secondary ball milling for 6-8h, and drying aft...

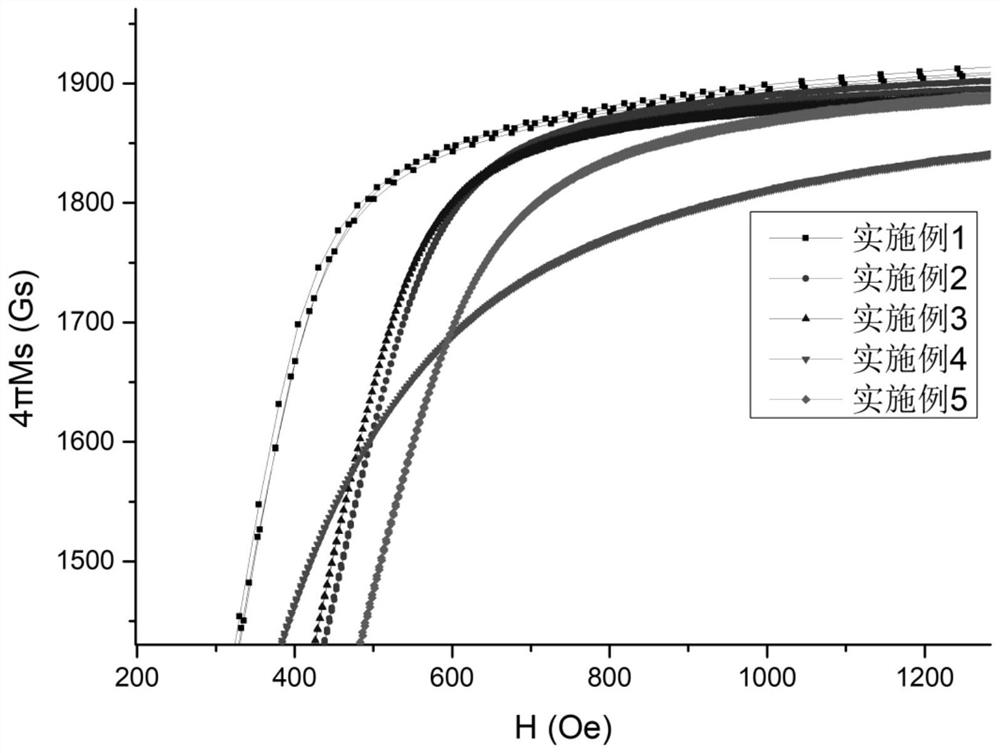

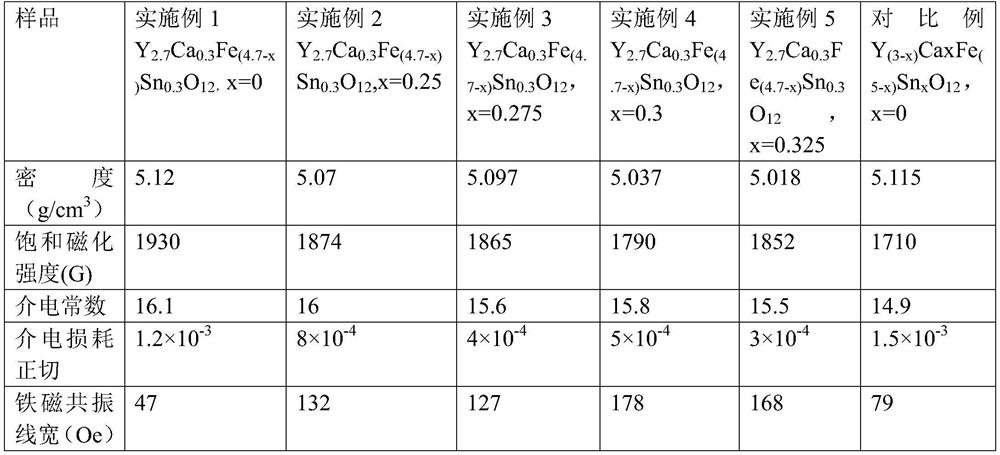

Embodiment 1

[0045] The present embodiment provides a method for preparing a low-loss YIG material, comprising the following steps:

[0046] (1) Step 1, the preparation of pre-sintered material:

[0047] (1.1) Using iron oxide, calcium oxide, yttrium oxide and tin oxide as raw materials, according to Y 2.7 Ca 0.3 Fe (4.7-x) Sn 0.3 O 12 , the ratio of x=0 is weighed and the raw material is weighed, and then placed in a nylon tank with deionized water as the medium for one-time ball milling for 6-9h; the rotating speed is 260r / min;

[0048] (1.2) After drying and sieving the primary ball abrasive obtained in step 1.1, pre-fire at 1200°C for 4-5h, and then cool to room temperature with the furnace;

[0049] (2) Step 2, secondary ball milling:

[0050] The pre-sintered material obtained in step 1 is placed in a nylon tank, and deionized water is added to carry out secondary ball milling for 6-8h, the rotating speed is 260r / min, and drying is completed after the ball milling;

[0051] (3) ...

Embodiment 2

[0057] The difference between this example and Example 1 is that x=0.25 in step 1.1, and the remaining steps are the same as those of Example 1.

[0058] The properties of the YIG ferrite material prepared in Example 2 are:

[0059] Saturation magnetization 1874Gs, dielectric constant 16, dielectric loss tangent 8×10 -4 , the ferromagnetic resonance linewidth is 132Oe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com