Composite magnetic body and method for producing the same

A technology of composite magnetic body and metal magnetic powder, which can be used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., and can solve the problems of insufficient use of transformers and choke coils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

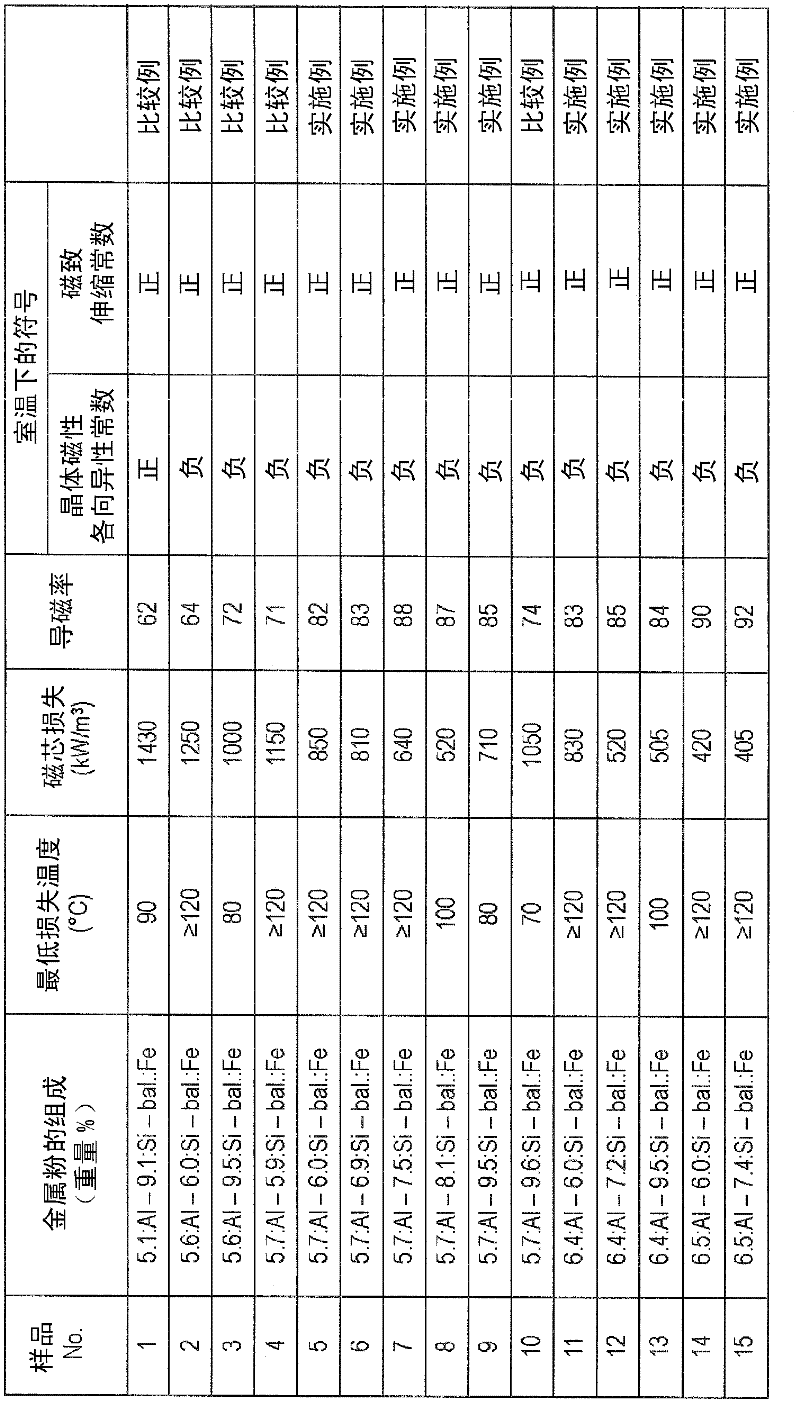

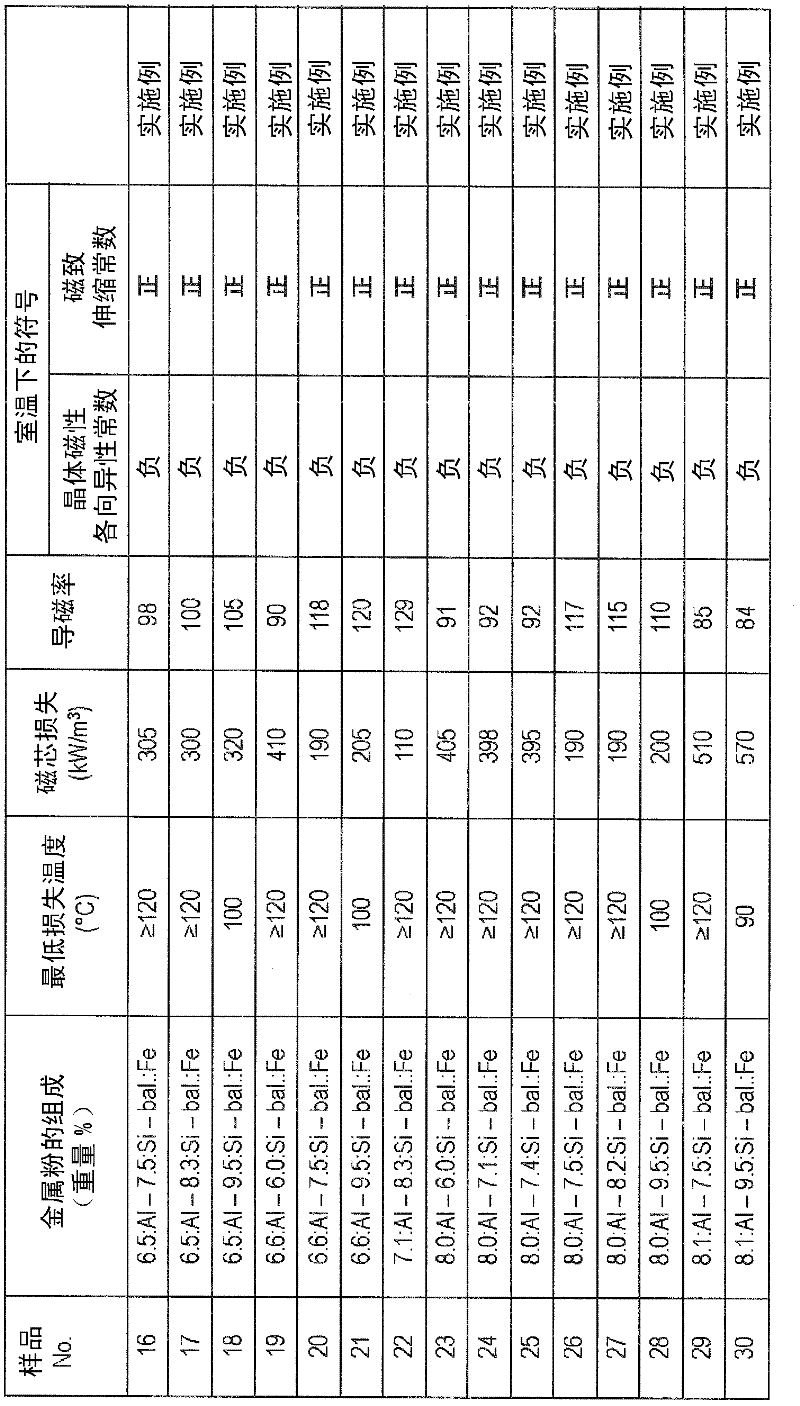

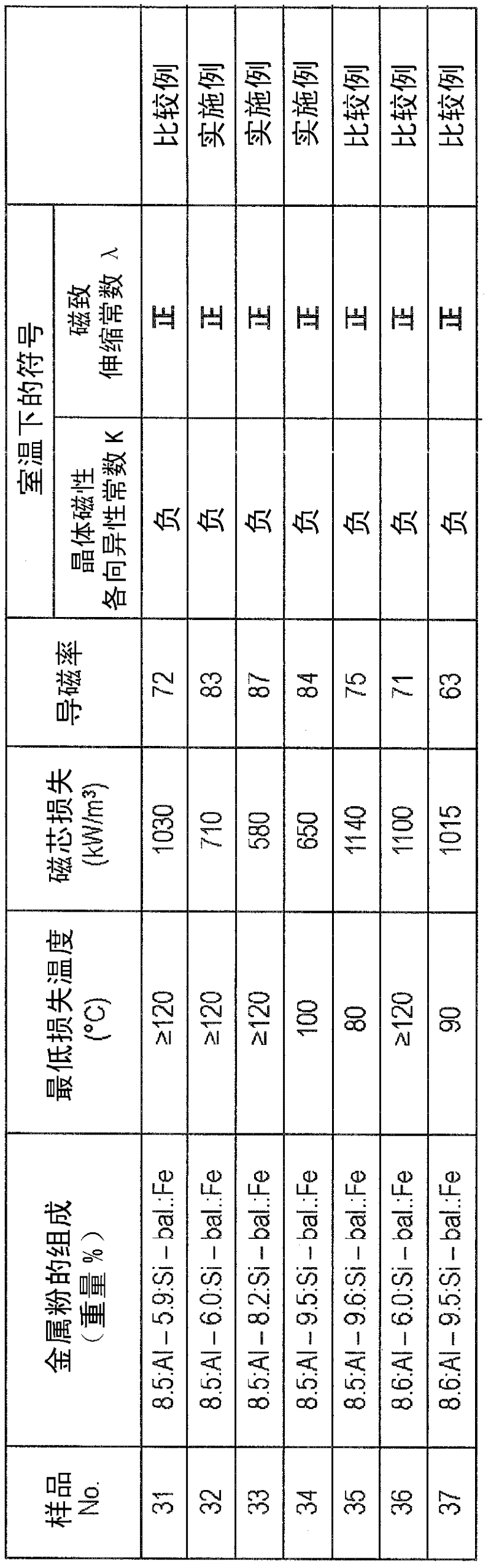

Embodiment 1

[0047] prepared with an average particle size of 15 μm Figure 1A ~ Figure 1C The metal magnetic powder of the composition described in. After adding 1.0 parts by weight of silicone resin as an insulating binder to 100 parts by weight of the prepared metal magnetic powder, and adding 1.0 parts by weight of butyral resin as a bonding aid, add a small amount of toluene to mix and disperse , thus making a mixture. For the resulting mixture at 12ton / cm 2 The pressure was press-molded, and heat-treated at 820°C for 60 minutes in a nitrogen atmosphere with a purity of 5N to prepare a sample. In addition, the produced sample is a toroidal core having an outer diameter of 14 mm, an inner diameter of 10 mm, and a height of about 2 mm. figure 2 It is a perspective view of the molded body of the composite magnetic body in embodiment. The shape of the molded body is not limited to a ring shape, and there are shapes with magnetic cores of various shapes. Figure 1A ~ Figure 1C The co...

Embodiment 2

[0053] A metal magnetic powder having an average particle diameter of 30 μm and having a composition of 6.7% by weight of Al, 8.4% by weight of Si, and the remainder of Fe was prepared. After adding 0.9 parts by weight of silicone resin as an insulating binder to 100 parts by weight of the prepared metal magnetic powder, and adding 1.0 parts by weight of butyral resin as a bonding aid, add a small amount of toluene to mix and disperse , thus making a mixture. For the resulting mixture, use 5 to 15 ton / cm 2 The pressure is press-molded, and heat-treated in the range of 500-820°C for 30-60 minutes in a nitrogen atmosphere with a purity of 6N, and impregnated in epoxy resin. Figure 4 The retention force of the prepared samples is shown. In addition, the shape of the produced sample is a toroidal core having an outer diameter of 14 mm, an inner diameter of 10 mm, and a height of about 2 mm.

[0054] Magnetic permeability and core loss were evaluated for the obtained samples. ...

Embodiment 3

[0057] Prepared with a composition of 8.0% by weight Al, 8.2% by weight Si, and the rest Fe Figure 5 The metal magnetic powder with the average particle size. After adding 1.0 parts by weight of silicone resin as an insulating binder to 100 parts by weight of the prepared metal magnetic powder, and adding 1.0 parts by weight of butyral resin as a bonding aid, add a small amount of toluene to mix and disperse , thus making a mixture. For the resulting mixture at 10 ton / cm 2 After degreasing by heating at 350°C in the air for 3 hours, heat treatment was performed at 780°C for 30 minutes in a nitrogen atmosphere with a purity of 5N. In addition, the produced sample is a toroidal core having an outer diameter of 14 mm, an inner diameter of 10 mm, and a height of about 2 mm.

[0058] Magnetic permeability and core loss were evaluated for the obtained samples. The magnetic permeability is measured with an LCR measuring instrument at a frequency of 120KHz. In addition, the core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com