Transverse exchange-coupled magnetic information storage medium material and preparation method thereof

A technology of exchange coupling and storage media, which is applied to the manufacture of magnetic materials, magnetic layers, and disc carriers of record carriers, and can solve the problems of increased flip field distribution of information storage units and reduced stability of information recording, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

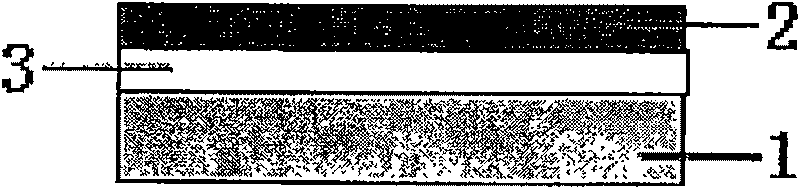

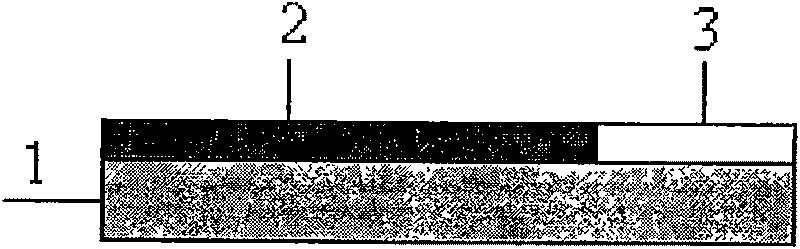

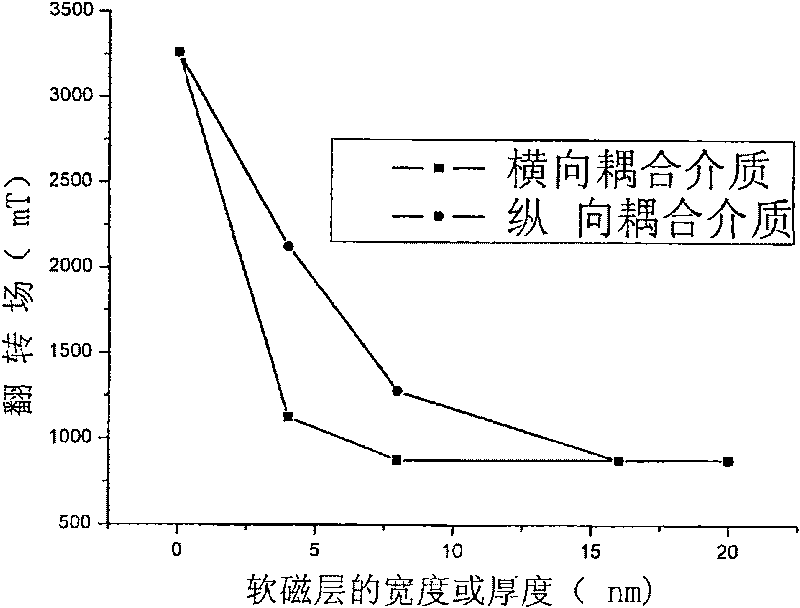

Method used

Image

Examples

specific Embodiment approach 1

[0018] (1) According to the requirements of surface density, the area of each magnetic information storage unit is determined to be 40nm×40nm, and the magnetic information storage material is FePt alloy with a thickness of 10nm;

[0019] (2) Prepare a FePt alloy thin film with a thickness of 10nm by DC magnetron sputtering process on the recording disc, wherein the sputtering target material is Fe50Pt50 (atomic ratio), the purity is 99.9%, and the sputtering process is background vacuum-7 mbar; argon sputtering pressure 5×10 -3 mbar with a power of 250W.

[0020] (3) Put the magnetic film-coated disk in the vacuum annealing furnace, and vacuumize to 1×10 -4 Below mbar, flush with hydrogen to a pressure of 2×10 -5 mbar, annealed at 580°C for 1 hour to make the magnetic film with L 10 A high anisotropy constant magnetic thin film 2 whose magnetic anisotropic easy axis of the phase structure is oriented along a direction perpendicular to the substrate.

[0021] (4) Place the...

specific Embodiment approach 2

[0022] Similar to Embodiment 1, only the ion beam implantation process is changed to the ion diffusion process.

specific Embodiment approach 3

[0023] Similar to Embodiment 1, only the FePt alloy material is changed to CoPt, SmCo or NdFeB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com