Evaluation method for auto sheet texture

An evaluation method, the technology of automotive sheets, applied in the direction of material analysis using radiation diffraction, etc., can solve the problems of improper texture options, lack of equipment and technology in the laboratory, complex measurement and calculation, etc., and achieve the effect of improving the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but these embodiments should not be construed as limiting the present invention.

[0020] 1. Sample:

[0021] 1# sample - WH180Y automobile plate;

[0022] 2# sample - WH180B automobile plate;

[0023] 3# sample-DC04 automobile plate;

[0024] 4# sample-DC06 automobile plate.

[0025] 2. Steps:

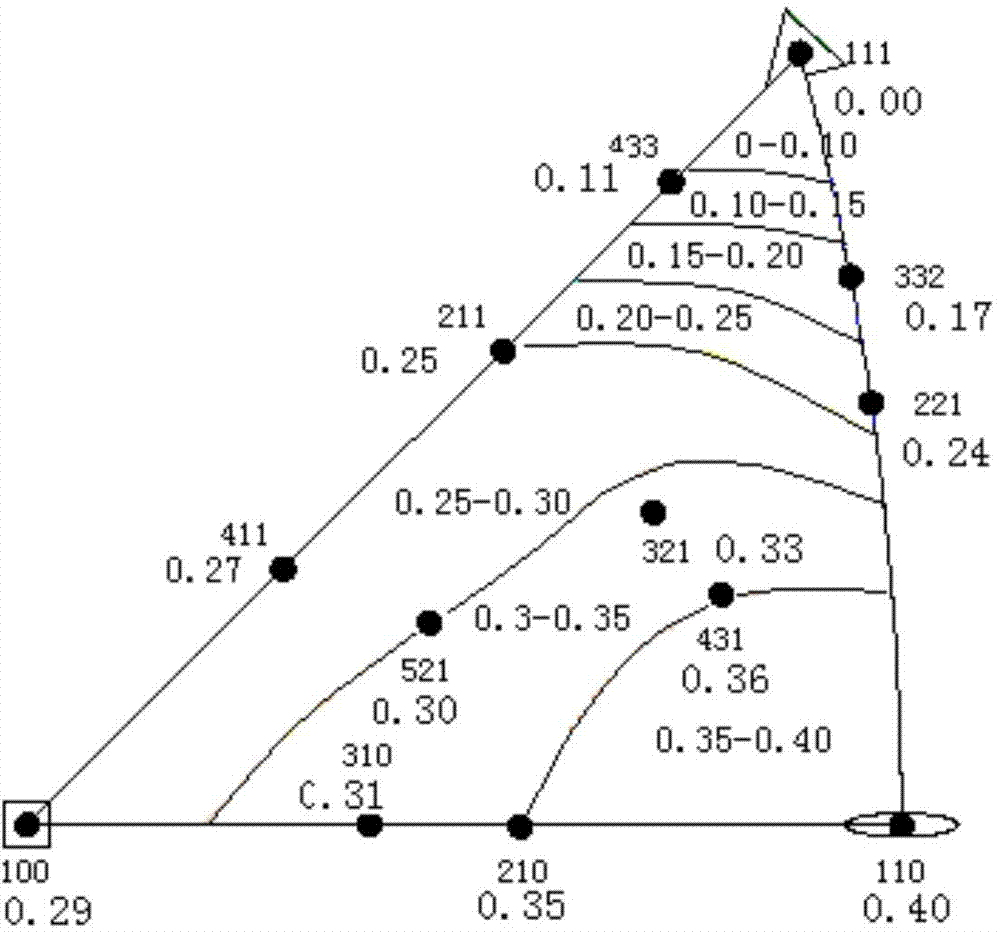

[0026] S1. Calculate the auricular index q of different crystal planes:

[0027] S11. Calculate the anisotropy constant m of each [uvw] in the {hkl} crystal plane with formula (1):

[0028] m = 1 - A 1 2 A 2 2 + A 2 2 A 3 2 + A 3 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com